Explosion-proof valve capable of rotating by 360 degrees

A valve and valve body technology, applied in the field of explosion-proof valves, can solve problems such as breakpoints and valve collapse, and achieve the effect of reducing product risks and avoiding large-scale leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

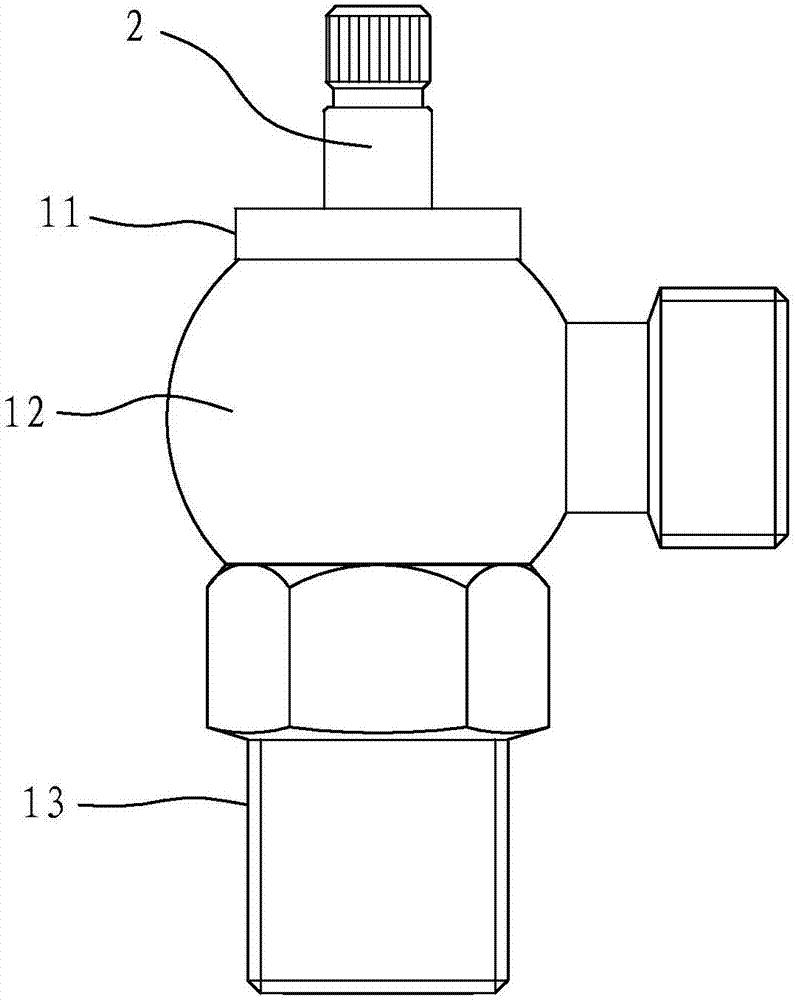

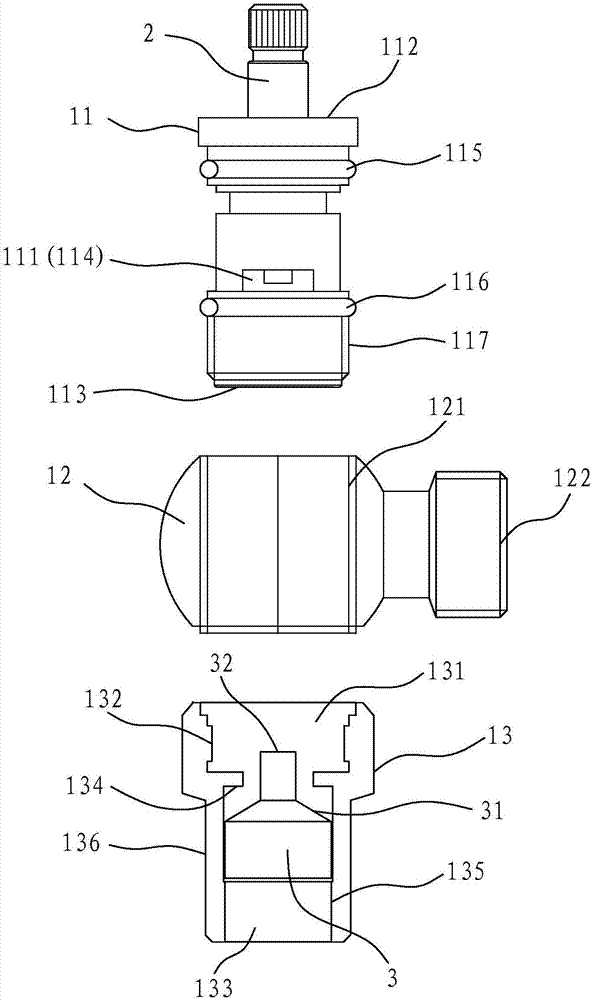

[0034] Such as Figure 1 to Figure 3 As shown, the invention relates to a 360-degree rotatable explosion-proof valve, including a valve body, a water inlet, a water outlet, a control valve core 2 and a water flow channel.

[0035] Such as figure 2 As shown, the innovation of the present invention is that the valve body is divided into a first valve body 11 , a second valve body 12 and a third valve body 13 .

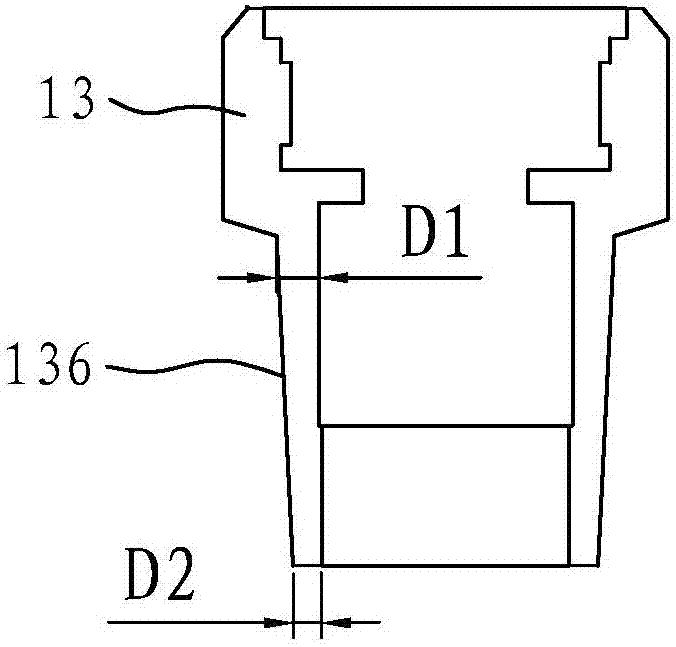

[0036] Wherein, the first valve body 11 has an accommodating chamber 111, the accommodating chamber 111 is formed with a first opening 112 and a second opening 113 in the axial direction of the first valve body 11, and the control valve core 2 is inserted through the first opening 112 The accommodating chamber 111 closes the first opening 112 , the accommodating chamber 111 forms a third opening 114 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com