Gas turbine combustor

A technology of gas turbines and combustion chambers, applied in the direction of combustion chambers, continuous combustion chambers, combustion methods, etc., can solve problems such as flame tube damage, achieve the effect of increasing output power and reducing the probability of oscillating combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to improve the combustion state of the combustion chamber, reduce the probability of oscillating combustion in the combustion chamber, and thereby improve the output power, output stability and service life of the gas turbine, an embodiment of the present invention provides a gas turbine combustion chamber. In order to make the purpose, technical solution and advantages of the present invention clearer, the following examples are given to further describe the present invention in detail.

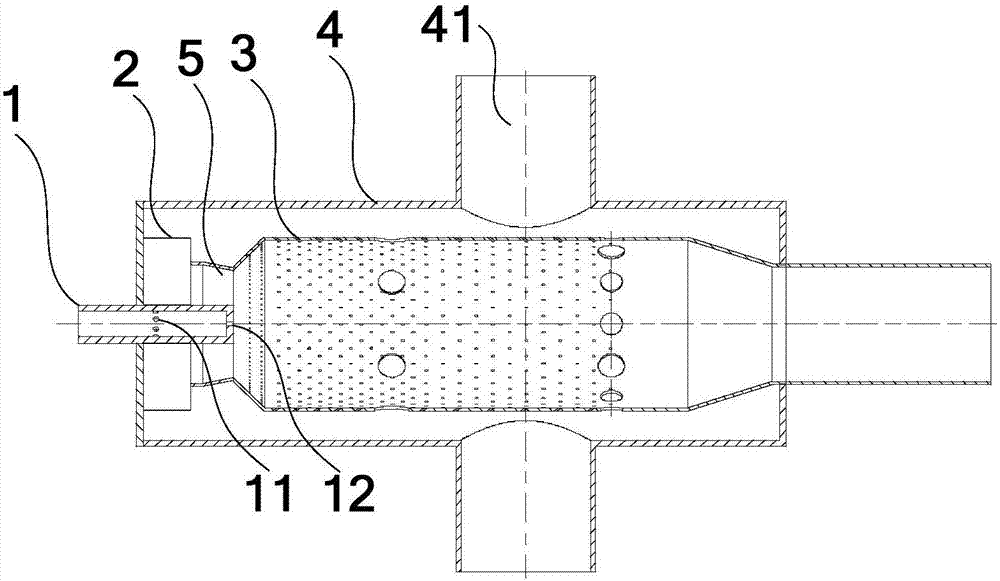

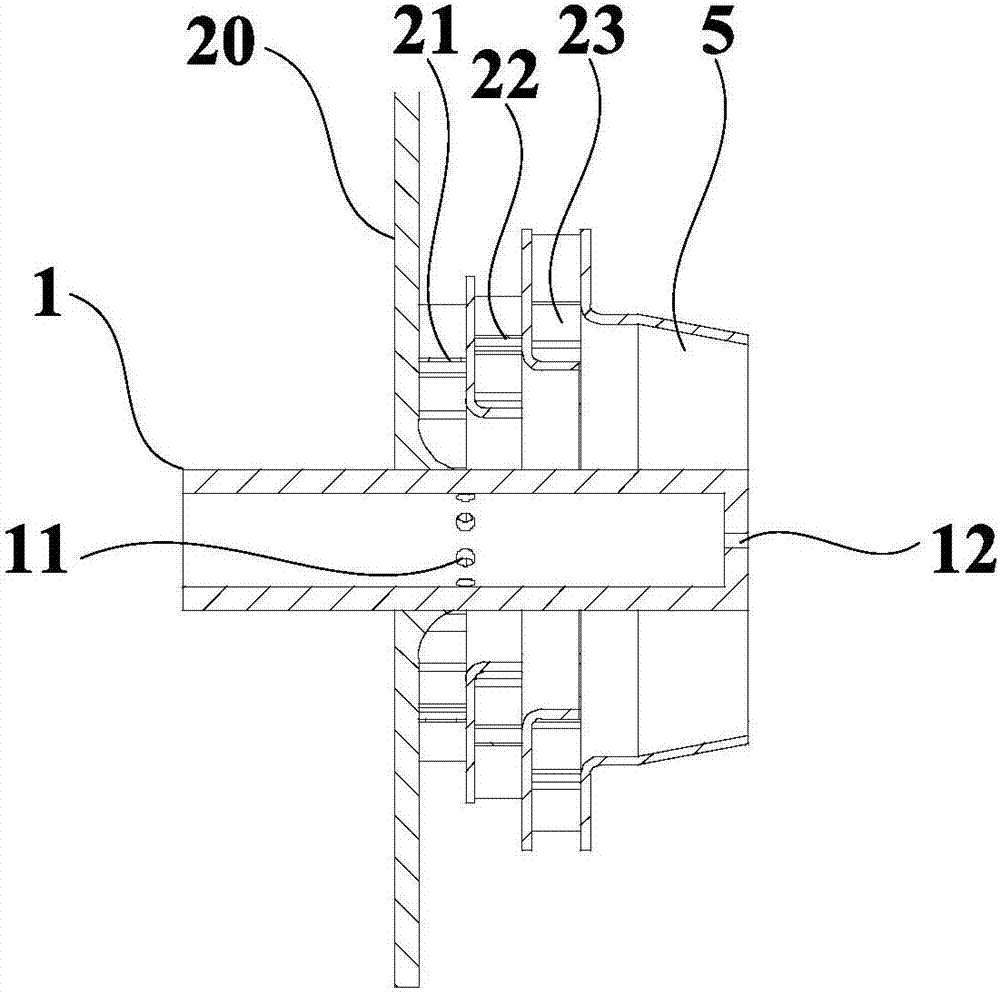

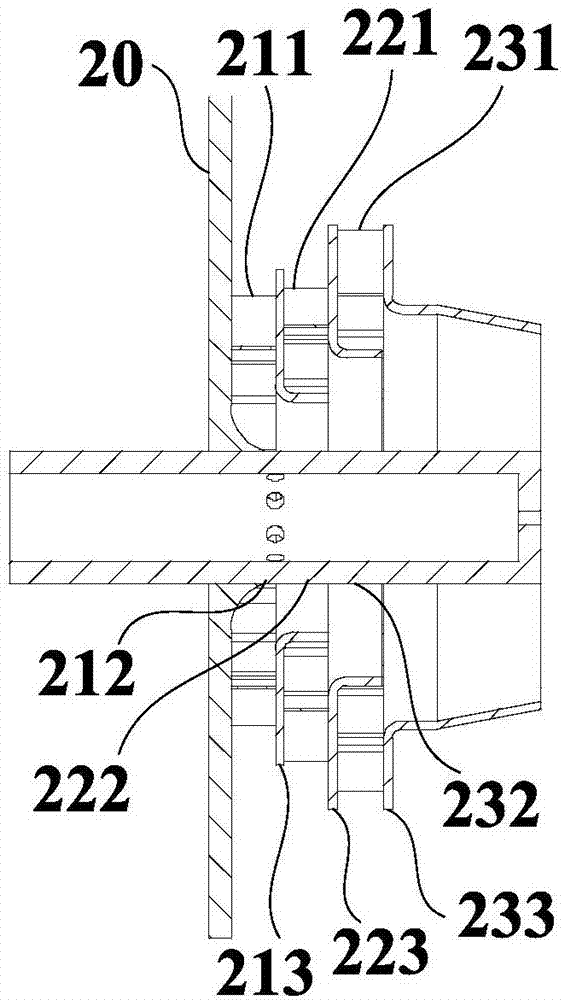

[0047] refer to figure 1 , the gas turbine combustor provided by an embodiment of the present invention includes a fuel nozzle 1, a multi-stage swirler group 2, a flame tube 3 and a turbine casing 4, wherein the multi-stage swirler group 2 is in the shape of a hollow cylinder, and the fuel The side wall of the middle section of the nozzle 1 has a first fuel injection hole 11, and the end of the outlet side of the fuel nozzle 1 has a second fuel injection hole 12. The fuel noz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com