A Test System for Heat Transfer and Flow Characteristics of Multiple Hydrocarbon Mixed Refrigerant Heat Exchangers

A technology of mixed refrigerant and flow characteristics, which is applied in the field of heat exchanger thermal performance test system, can solve the problems of heat exchange elements that have not yet been localized, large impact on energy consumption, high reliability and high efficiency, and achieve rebalancing of the ratio , to achieve secondary voltage regulation, to achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

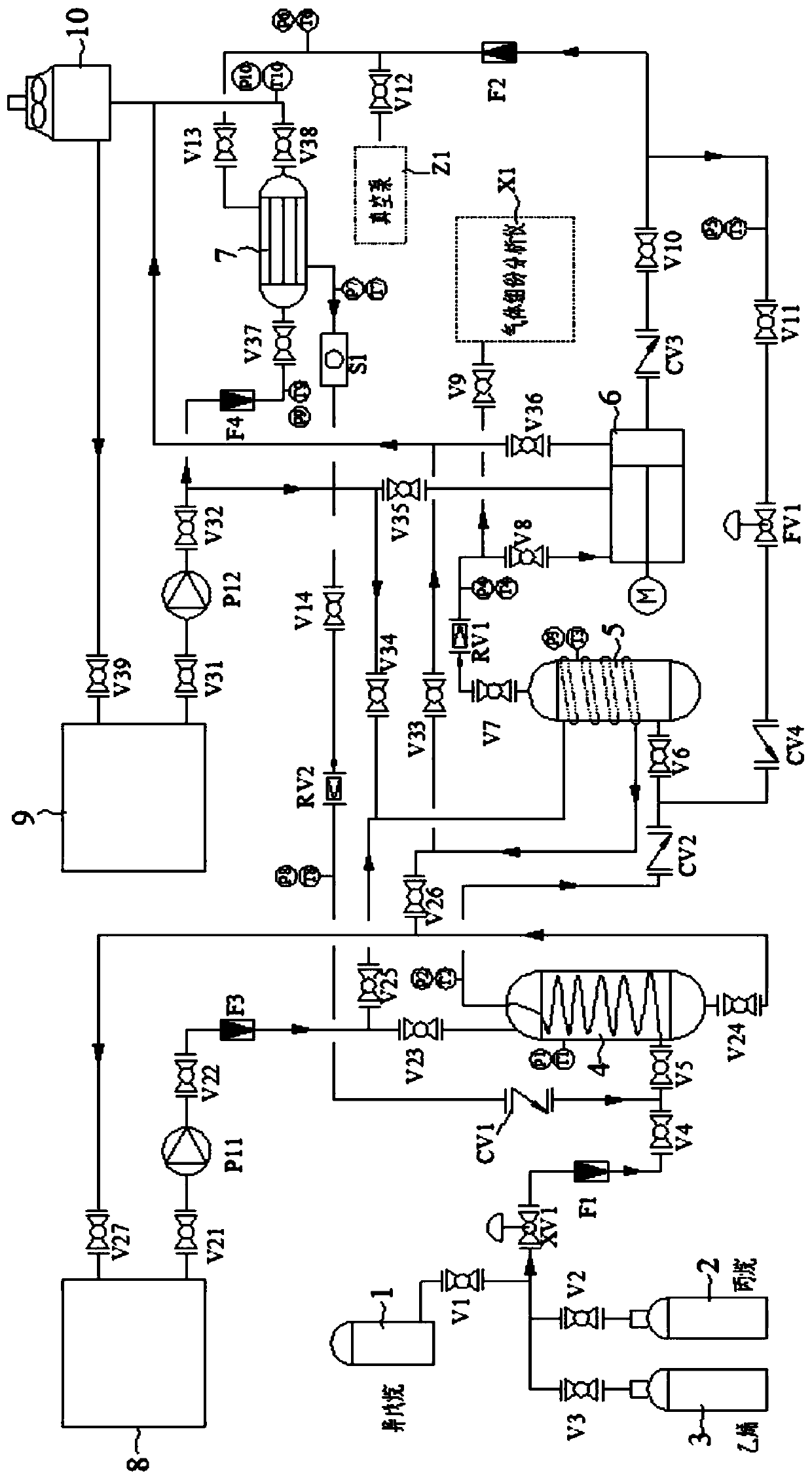

[0041] Such as figure 1 As shown, the test prototype is a proportional prototype of the compressor stage aftercooler in the DMR liquefied natural gas process flow. Its structure is an internal wave and external threaded tube + a spiral baffle heat exchanger. For the mixed refrigerant composed of ethylene, propane and isopentane, the test parameters are as follows:

[0042] The following table 1 is the mixed refrigerant parameters in the present embodiment:

[0043] category

Component (molar ratio)

Vinyl C 2 h 4

0.410449

Propane C 3 h 8

0.498986

Isopentanei-C 5 h 12

0.090565

[0044] Wherein the above-mentioned isopentane i-C 5 h 12 Filled in heavy hydrocarbon material tank 1, propane C 3 h 8 Filled in light hydrocarbon material tank 2, ethylene C 2 h 4 Filled in the olefin material tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com