Dynamic tensile experimental device for detecting mechanical performance and microstructure of high polymer fiber on line

A microstructural, dynamic stretching technique used in measuring devices, testing material strength using applied stable tension/pressure, scientific instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In this embodiment, a dynamic tensile test device for on-line detection of the mechanical properties and microstructure of polymer fibers is mainly composed of a stretcher, an X-ray diffractometer and a sample fixing device. Both the sample fixing device and the extensometer are fixed in the X-ray diffractometer, and the sample fixing device is located on the diffraction optical path of the X-ray diffractometer.

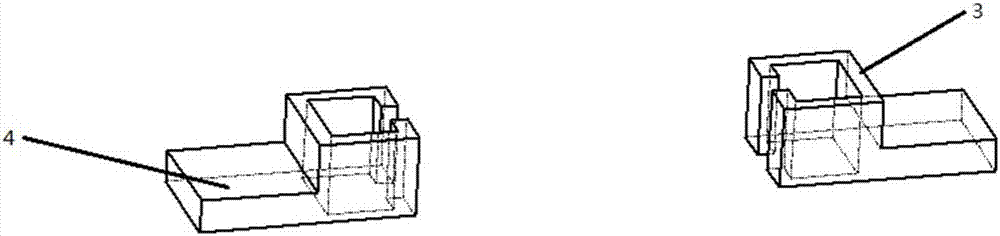

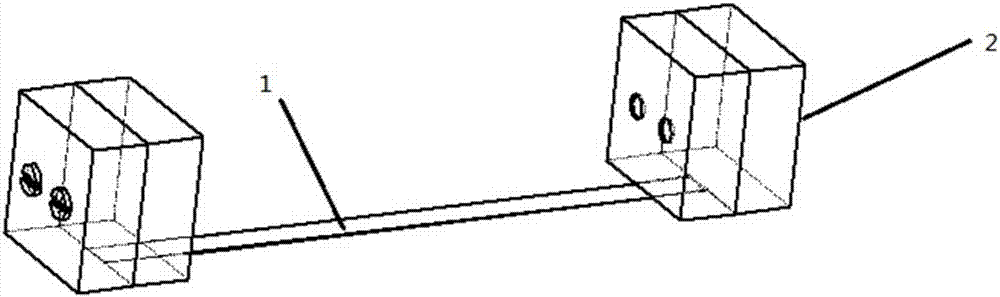

[0020] Wherein, the sample fixing device is composed of a sample box 8 and a sample box cover plate 12 to form a hollow square cylindrical cylinder; the middle part of the cylinder is a through hole 9; the middle part of the cylinder is a through hole 9; Stretch rod sliding positioning groove 10; Stretch rod 4 is installed in the stretch rod sliding positioning groove 10, is connected to the stretching jig of extensometer for the stretch rod 4 that is exposed outside sample box 8; Stretch rod 4 The number is 2, and the opposite position of the two stretching r...

Embodiment 2

[0022] The difference between this embodiment and Embodiment 1 is that a fixing screw 11 is provided on the sliding positioning groove 10 of the stretching rod; by loosening one or two fixing screws, one-way or two-way stretching can be performed on the fiber bundle sample. operate.

Embodiment 3

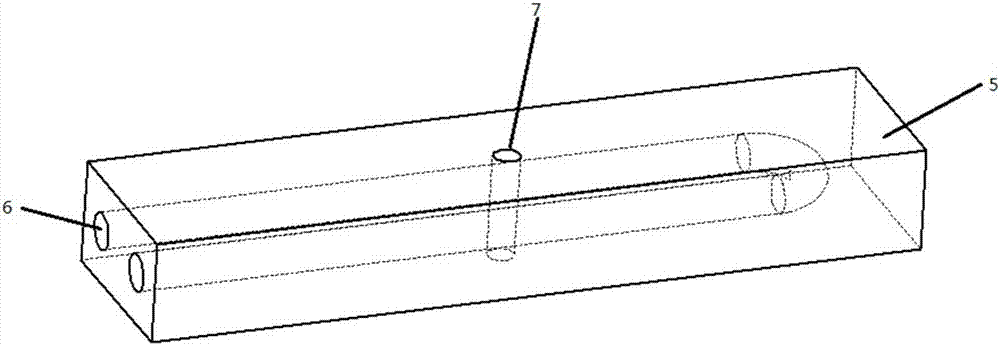

[0024] The difference between this embodiment and embodiment 1 is that a vapor chamber 5 is installed at the bottom of the sample box 8; 7 is connected to the electric temperature control instrument; when the vapor chamber 5 is installed, the upper surface of the vapor chamber 5 must be in contact with the plane composed of the high polymer fiber bundle 1, the fiber bundle transfer fixture 2 and the stretch rod 4 and can slide each other; the temperature chamber 5 is preferably made of copper or aluminum material with good temperature uniformity.

[0025] In the above embodiments, the X-ray diffractometer equipped with a two-dimensional detector is selected, and its diffraction detection range is not less than 60 degrees, and the angular separation rate of diffraction lines is not less than 0.04 degrees.

[0026] The high polymer fiber tensile test device is applicable to fiber monofilaments and fiber bundles. In order to be able to connect with the X-ray diffractometer, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com