High-precision second neutron bunch switch

A high-precision, neutron beam technology, applied in the direction of material analysis using radiation diffraction, etc., can solve the problem of low repeat positioning accuracy, achieve the effect of fast and convenient opening and closing, short movement time, and high repeat positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

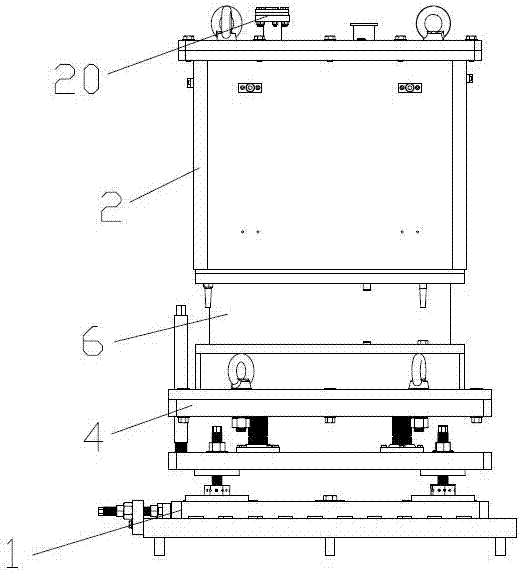

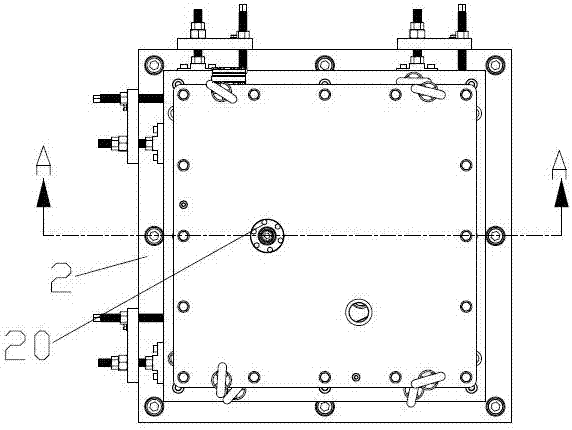

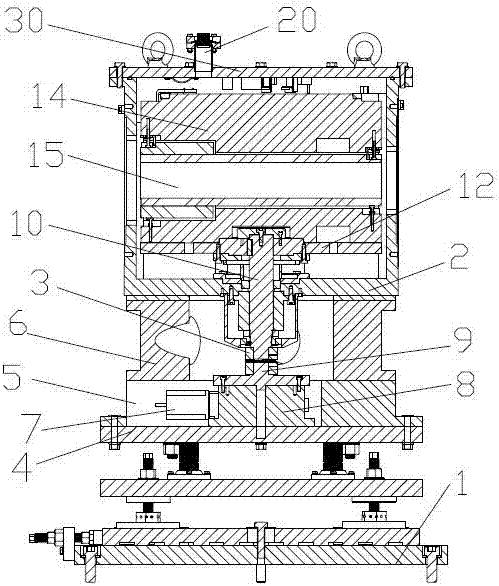

[0035] Such as Figure 1-11 As shown, a high-precision second neutron beam switch, the switch mainly includes a base 1 installed from bottom to top, a rotating system, a transmission system, a vacuum shell system, a rotary table system and a control system; wherein The rotation system is installed on the base 1, the transmission system is connected to the rotation system coaxially through the coupling 3, and the rotary table system is connected to the transmission system by coaxial rotation. The vacuum housing system has a vacuum housing 2, a housing 2 The upper surface is provided with lifting rings to facilitate hoisting and maintenance. The upper part of the transmission system and the rotating round table system are installed in the vacuum housing 2, and the control system is electrically connected to the rotating system. The structure of the vacuum housing 2 of the vacuum housing system and The vacuum method adopts the structure disclosed in the patent No. 201310399825.0 ...

Embodiment

[0042] Embodiment: Assume that the present invention is in an initial state, that is, the neutron conduit 15 is in a conduction state.

[0043] Such as Figure 13 As shown, when the neutron beam is closed, the motor 7 drives the high-precision turntable to rotate to generate torque, which is transmitted to the rotating disk through the rotating shaft 9, the coupling 3, and the transmission shaft 10, because the rotating disk 14 and the connecting disk 12 The system is fixed together by the fixed rod 13 and the screw, and then drives the rotating round table 14 to drive the neutron tube 15 inside to rotate. When the rotation reaches the 90° position, the second limit switch triggers the stopper 19 to trigger the third limit switch 23 And the fourth limit switch 24, the rotation stops, and the boron carbide block 16 is facing the neutron beam.

[0044] Such as Figure 12 As shown, when the neutron beam is turned on, the motor 7 reversely drives the high-precision turntable to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com