High-efficiency and high-precision measurement experimental device for natural convection heat transfer coefficient

An experimental device and high-precision technology, which is applied in the field of natural convection heat transfer coefficient measurement, can solve the problems of large error in experimental results, long experimental time, and large measurement error, and achieve the effects of reducing heat storage, improving experimental efficiency, and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

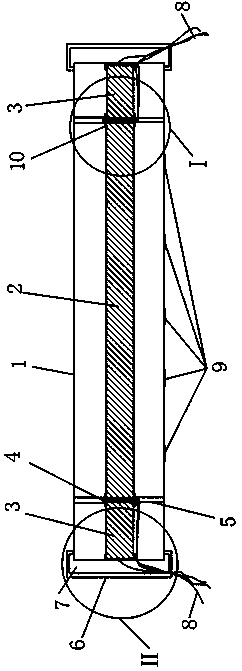

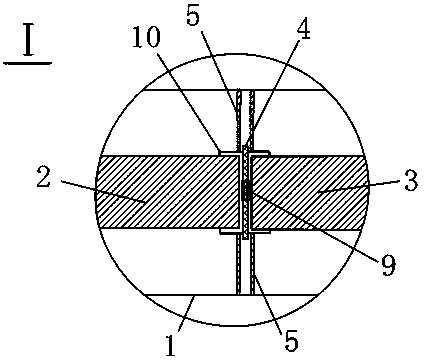

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The embodiments described below in conjunction with the accompanying drawings are exemplary and are intended to explain the present invention, but should not be construed as limiting the present invention.

[0026] The device measures the natural convection heat release coefficient based on the principle that the calorific value of the rated power heating tube is equal to the sum of the free convection heat transfer amount and the heat radiation amount to the environment. The experimental tube is heated, and the heat released by the experimental tube is dissipated to the environment in two ways: convection and radiation. When the experimental tube is in a thermally stable state, the heat released by the main heating rod is equal to the convective heat transfer of the tube wall of the effective test section to the environment and The sum of radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com