Biomass-based liquid fuel and production process thereof

A production process and liquid fuel technology, which is applied in the preparation of biofuels, liquid hydrocarbon mixtures, and the petroleum industry. It can solve the problems of complex process, low fuel utilization rate, and low biomass conversion rate, and increase the specific surface area. , Improve the catalytic activity, the effect of excellent catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

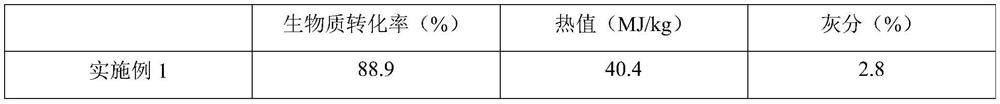

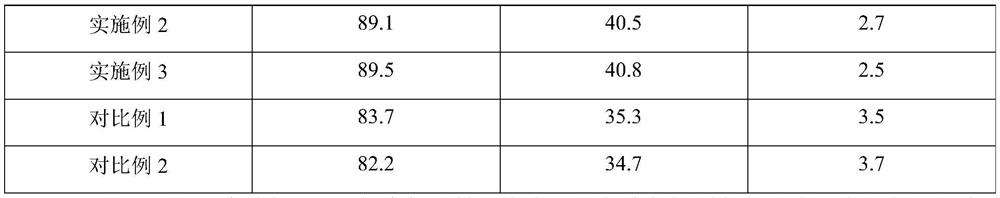

Embodiment 1

[0035] A kind of production process of liquid fuel based on biomass, with biomass (hemp stalk) as raw material, through pretreatment, pyrolysis reaction and catalytic cracking reaction, obtains liquid fuel; The catalyst is prepared by the following method:

[0036] (A) First prepare 100 parts of diatomaceous earth into a suspension, then add 65 parts of α-naphthylamine monomer to the suspension, undergo polymerization, filter and wash, roast and carbonize, and then disperse in water to make a solid content 40w.t.% carrier slurry;

[0037] (B) Then add 2 parts of tetraethyl orthosilicate and 4 parts of ZSM-5 molecular sieve to the acid solution with pH=3.5, stir and hydrolyze, dry and mix with 0.5 part of thiourea and grind evenly, roast to obtain composite powder, then Disperse the composite powder in water to make a molecular sieve slurry with a solid content of 40w.t.%.

[0038] (C) adding 0.04 parts of binder to the carrier slurry obtained in step (A), and ultrasonically ...

Embodiment 2

[0053] A kind of production process of liquid fuel based on biomass, with biomass (hemp stalk) as raw material, through pretreatment, pyrolysis reaction and catalytic cracking reaction, obtains liquid fuel; The catalyst is prepared by the following method:

[0054] (A) First prepare 100 parts of diatomaceous earth into a suspension, then add 75 parts of α-naphthylamine monomer to the suspension, undergo polymerization, filter and wash, roast and carbonize, and then disperse in water to make a solid content 30w.t.% carrier slurry;

[0055] (B) Then add 1 part of ethyl orthosilicate and 6 parts of ZSM-5 molecular sieve to the acid solution with pH=4.5, stir and hydrolyze, dry and mix with 0.3 part of thiourea and grind evenly, roast to obtain composite powder, then Disperse the composite powder in water to make a molecular sieve slurry with a solid content of 50w.t.%.

[0056] (C) adding 0.03 parts of binder to the carrier slurry obtained in step (A), and ultrasonically oscill...

Embodiment 3

[0071] A kind of production process of liquid fuel based on biomass, with biomass (hemp stalk) as raw material, through pretreatment, pyrolysis reaction and catalytic cracking reaction, obtains liquid fuel; The catalyst is prepared by the following method:

[0072] (A) First prepare 100 parts of diatomaceous earth into a suspension, then add 70 parts of α-naphthylamine monomer to the suspension, undergo polymerization, filter and wash, roast and carbonize, and then disperse in water to make a solid content 35w.t.% carrier slurry;

[0073] (B) Then add 1.5 parts of tetraethyl orthosilicate and 5 parts of ZSM-5 molecular sieve to the acid solution with pH=4, stir and hydrolyze, dry and mix with 0.4 part of thiourea and grind evenly, roast to obtain composite powder, then Disperse the composite powder in water to make a molecular sieve slurry with a solid content of 45w.t.%.

[0074] (C) adding 0.035 parts of binder to the carrier slurry obtained in step (A), and ultrasonically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com