Integrated pulse eddy current sensing infrared thermal imaging detection apparatus and detection method thereof

A detection device, pulsed eddy current technology, applied in the direction of material defect testing, etc., can solve problems such as inconvenience, functions that cannot meet customer needs, difficult application requirements, etc., and achieve the effect of flexible excitation detection, rich software functions, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

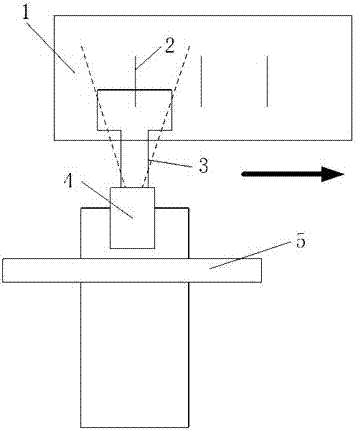

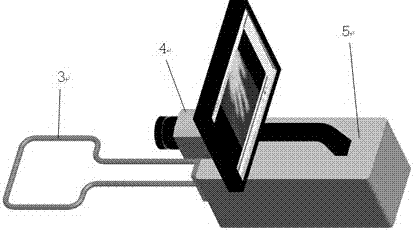

[0026] The integrated pulsed eddy current induction thermal imaging detection device provided by the present invention is as figure 1 , figure 2 , image 3 As shown, it includes an electromagnetic induction exciter 3 generating an alternating magnetic field, an infrared thermal imager 4 and an embedded industrial control panel 5. One end of the exciter coil of the electromagnetic induction exciter 3 is connected to the embedded industrial control panel 5, and the other end Align the crack defect 2 on the test piece 1; the infrared thermal imager 4 is connected to the embedded industrial control panel 5, and the infrared thermal imager 4 collects the infrared image on the test piece 1 and transmits it to the embedded industrial control panel.

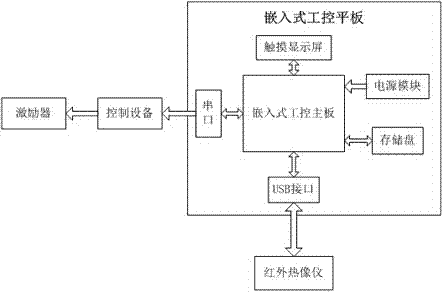

[0027] Described embedded industrial control panel 5 comprises embedded industrial control main board and is connected to the power supply module on the embedded industrial control main board, storage disk, touch screen, serial port an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com