Apparatus for triggering the electric tree of an epoxy resin insulating material by using variable pulse voltage

A pulse voltage, epoxy resin technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve problems such as breakdown, electrical equipment operation threat, uneven distribution of epoxy resin electric field, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

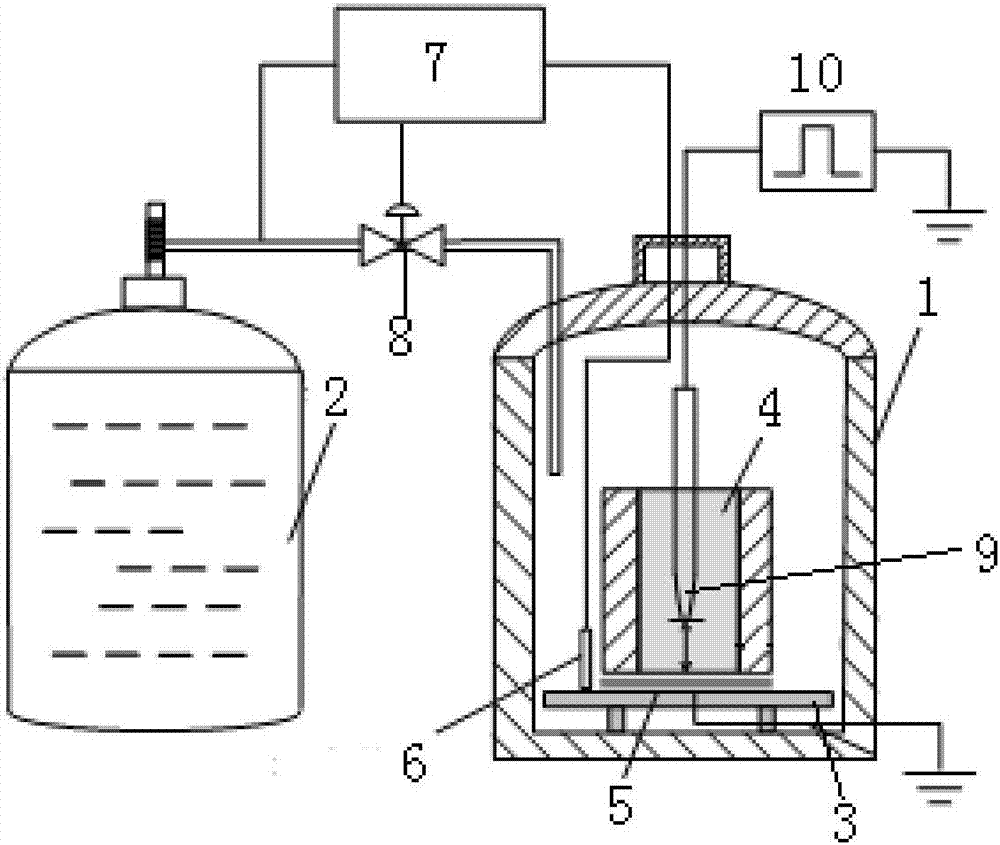

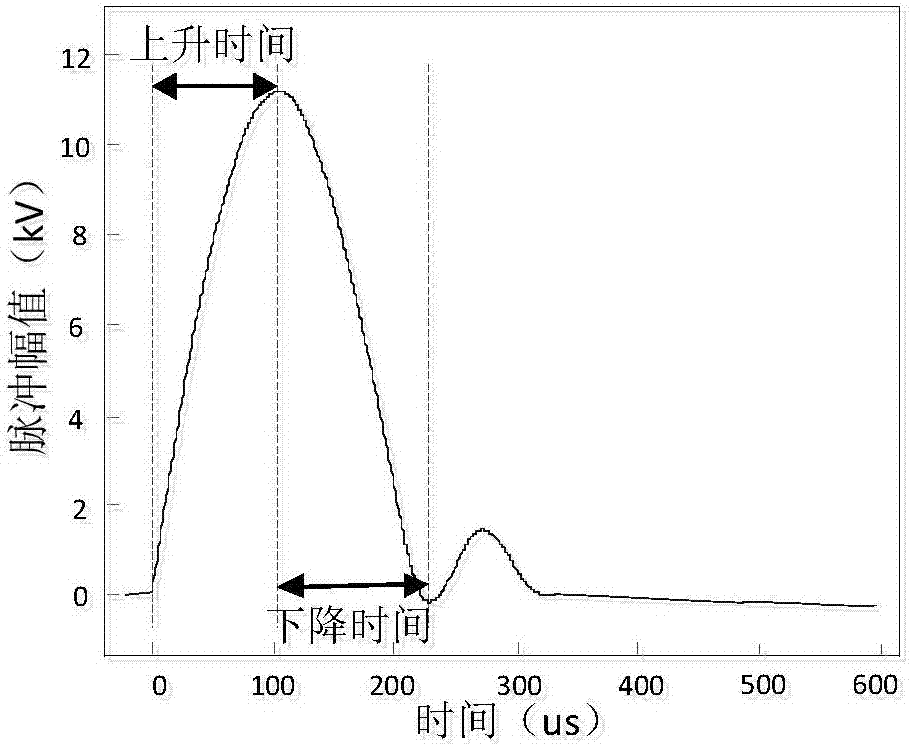

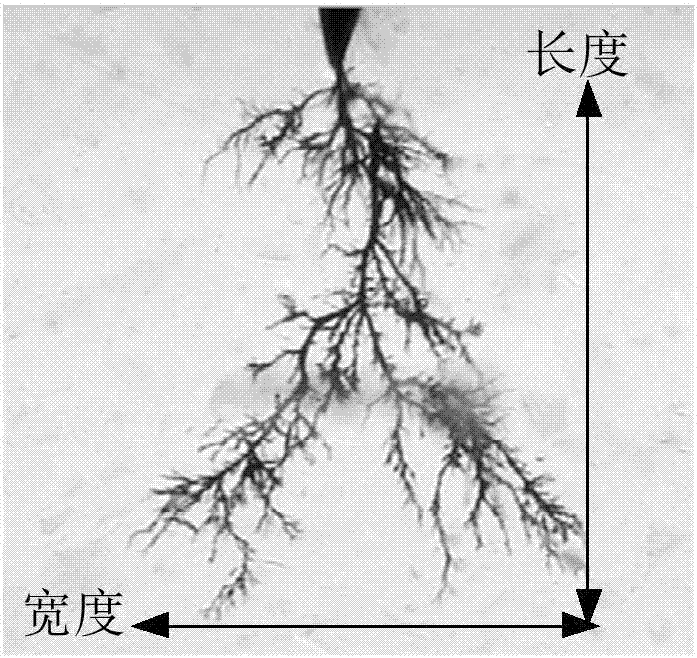

Method used

Image

Examples

Embodiment

[0034] 1. Preparation of epoxy resin insulation samples.

[0035] The samples used were prepared from high activity and low viscosity liquid epoxy resin (bisphenol A, HY-511 type) and curing agent polyamide resin (HY-651 type) produced by Tianjin Yanhai Chemical Co., Ltd. First, take an appropriate amount of epoxy resin and curing agent and pour it into a beaker at a ratio of 3:1 to mix, and stir the mixture at a constant speed with a magnetic stirrer for 20 minutes to make the liquid evenly mixed; then, vacuum the mixed liquid in a vacuum box for 2 hours , to remove internal air and moisture; after the above process is completed, the uncured epoxy liquid is poured into a custom-made mold. In order to simulate the actual defects inside the epoxy sleeve, metal silver needles are inserted into the mold in advance to form a pin-plate Electrode structure, before using the needle electrode, put it under a digital magnifying glass for magnification inspection, remove the needle elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com