Touch control module window hidden type clinging structure

A touch module and hidden technology, applied in the fields of instruments, computing, electrical and digital data processing, etc., can solve the problems of large visual contrast between the touch window and the panel ink area, affecting the visual effect of the touch panel, and shortage of supply resources, etc. , to meet the differentiated needs of customers, compact structure, low scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

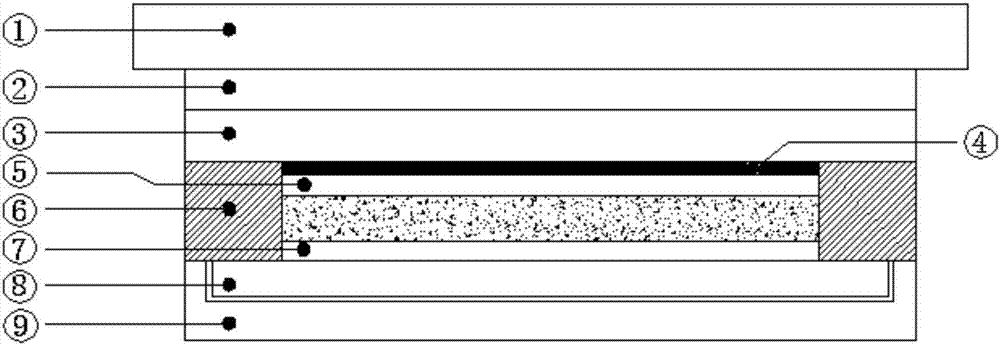

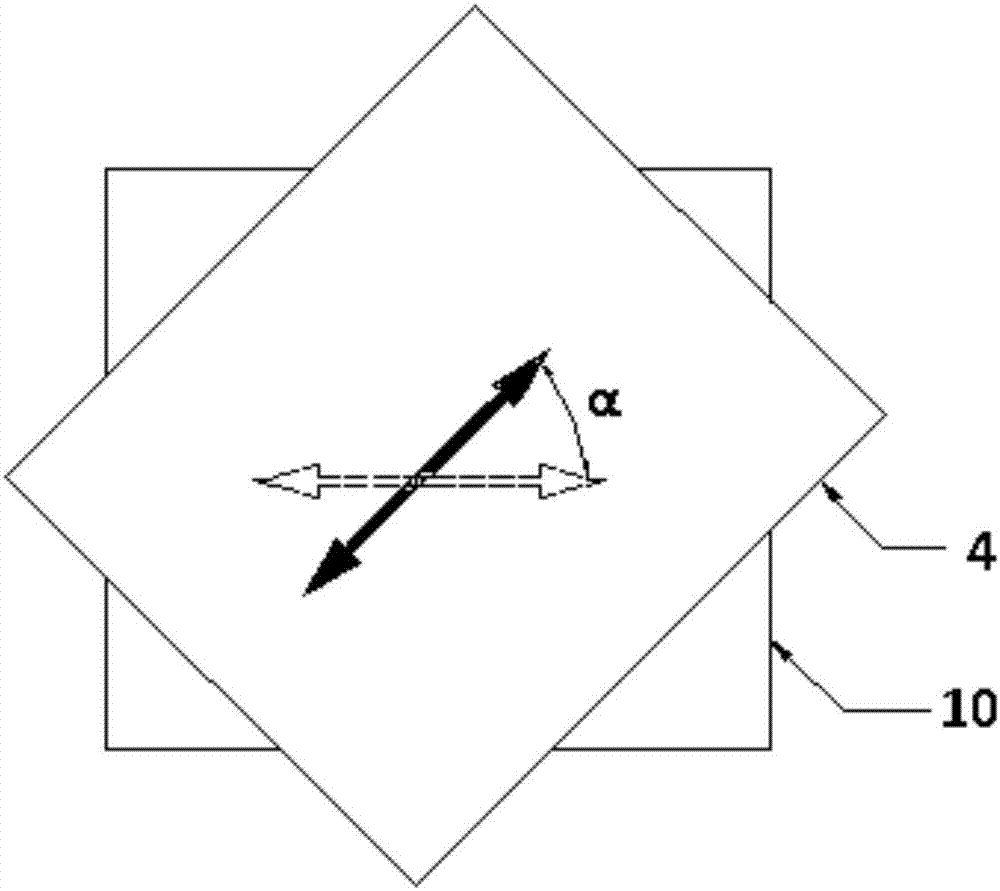

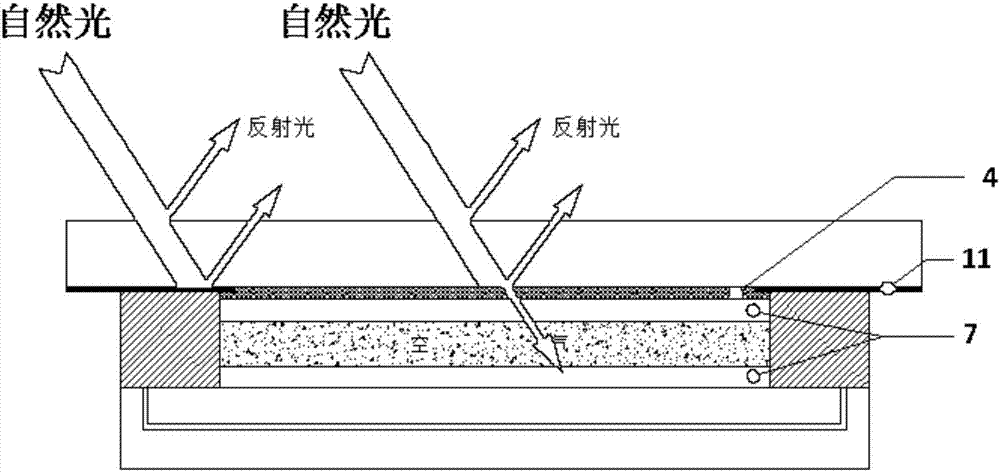

[0017] see Figure 1-4 , a touch module window hidden bonding structure, including touch screen glass cover plate 1, transparent optical adhesive 2, touch screen functional sheet 3, polarizer 4, ultra-low reflection film A5, ultra-low Reflective film B7, LCD 8 and backlight plate 9; the upper end of the polarizer 4 is attached to the lower end of the touch screen functional sheet 3, the lower end of the polarizer 4 is attached to the upper end of the ultra-low reflection film A5, and the touch screen includes a touch screen glass cover plate 1, transparent optical glue 2 and The touch screen functional sheet 3, the touch screen glass cover 1 and the touch screen functional sheet 3 are connected through transparent optical glue 2; there is a gap between the ultra-low reflection film A5 and the ultra-low reflection film B7, and the lower end of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com