Simulation turntable self-correction control method based on model parameter accurate identification

A self-calibration control and model parameter technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as inability to guarantee the best performance of the system, poor adaptability to load changes, and inability to guarantee system stability. Achieve saving manpower and material resources, strong adaptability, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

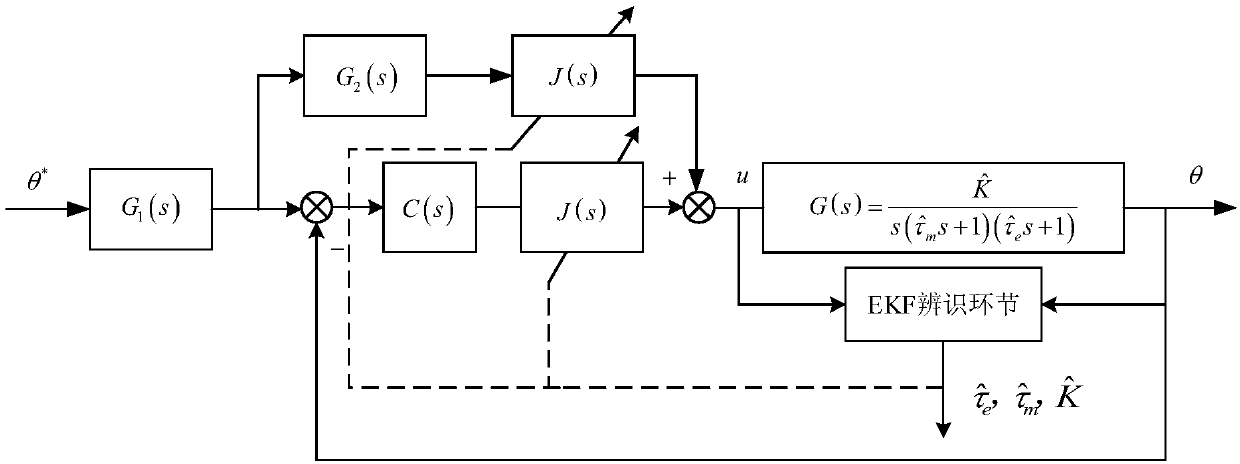

[0027] Specific implementation mode 1: The specific process of a simulation turntable self-calibration control method based on accurate identification of model parameters in this implementation mode is as follows:

[0028] In order to solve the problem that the dynamic performance index of the turntable model cannot be satisfied due to the parameter change, it is necessary to design an offline or online parameter identification method for the turntable model, to identify the changing mathematical model of the controlled object, and use the identification obtained The parameters are adjusted to the original servo control system, so that the system can effectively overcome the impact of load changes.

[0029] Step 1. According to the structure of the turntable servo system ( figure 2 ) to establish the mechanism model of the turntable servo system, including the open-loop transfer function model G(s) and the friction model of the turntable servo system

[0030] Step 2. Measu...

specific Embodiment approach 2

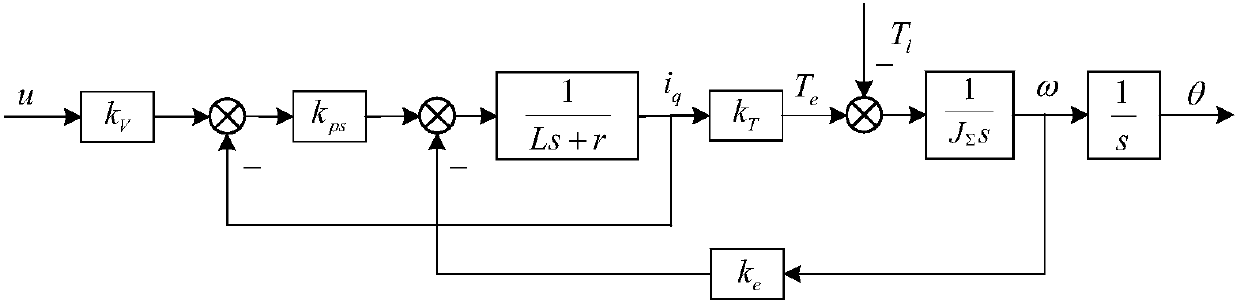

[0034] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in the step one, according to the structure of the turntable servo system ( figure 2 ) to establish the mechanism model of the turntable servo system, including the open-loop transfer function model G(s) and the friction model of the turntable servo system The specific process is:

[0035] The mechanism model of the turntable servo system is:

[0036]

[0037] In the formula, i d ,i q is the direct-axis current and quadrature-axis current in the synchronously rotating d-q coordinate system, d is the direct axis, q is the quadrature axis; ω r is the mechanical angular velocity of the motor; r is the armature resistance of the motor; r'=r+k V k ps k f is the equivalent resistance of the motor, k f is the motor current feedback amplification factor, k ps is the amplification factor of the motor driver, k V is the motor current amplification factor; L is the motor a...

specific Embodiment approach 3

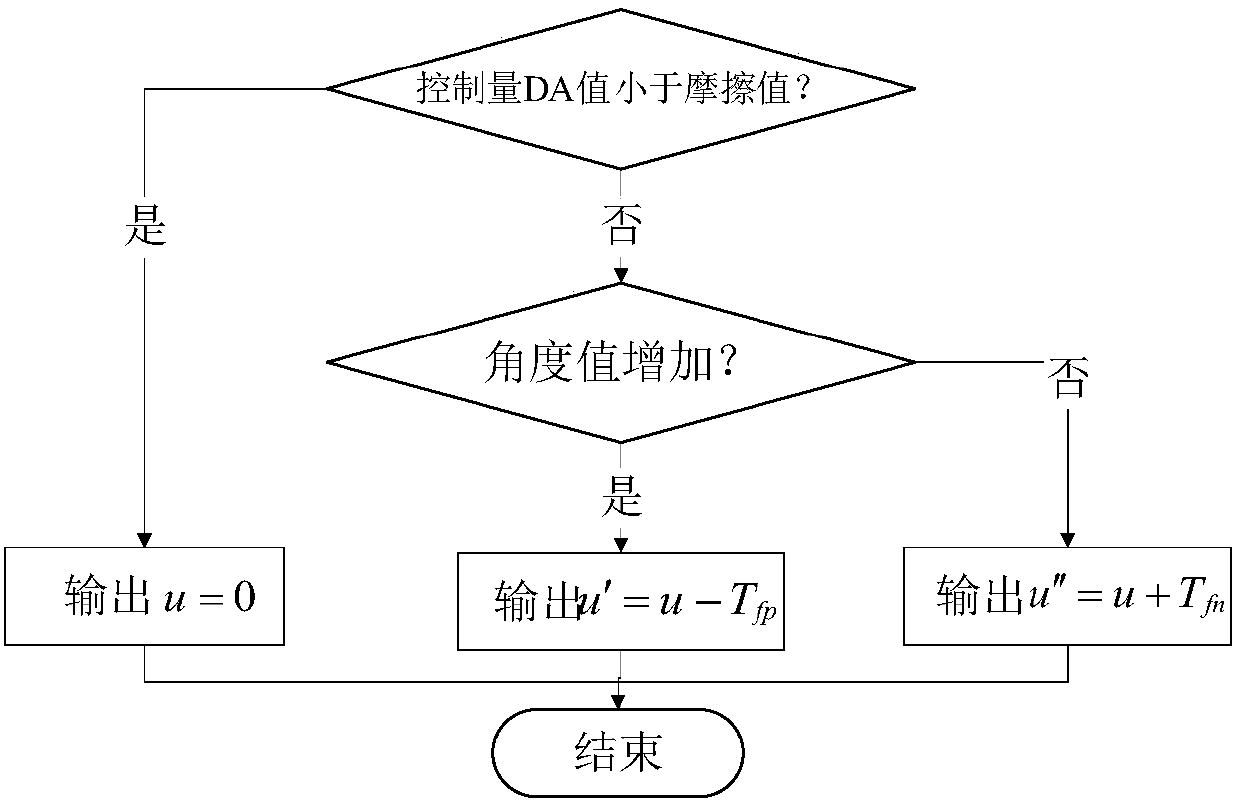

[0054] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that the specific form of the control input signal u of the turntable servo system in the step 1 is:

[0055] System identification requires that the input signal has continuous excitation within the system bandwidth range, so system identification generally uses white noise or M-sequence as the input signal. However, in the turntable system, the drastically changing input signal will lead to a large command acceleration, even exceeding the capability range of the turntable. On the one hand, it will cause the system to enter a saturated state, and on the other hand, it will also have a negative impact on the equipment under test and the turntable itself; If the amplitude of the input signal is small, the non-linear effects such as the friction dead zone will be obvious, which will seriously affect the identification results. Therefore, when selecting the input signal for iden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com