Assembly-type building labor force allocation method based on BIM

A labor and prefabricated technology, applied in the field of labor deployment of prefabricated buildings based on BIM, can solve the problems of insufficient working plane, limit the construction speed of prefabricated buildings, and fail to exert the maximum efficiency of construction team members, so as to accelerate the pace of construction. , Improve the effect of on-site operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

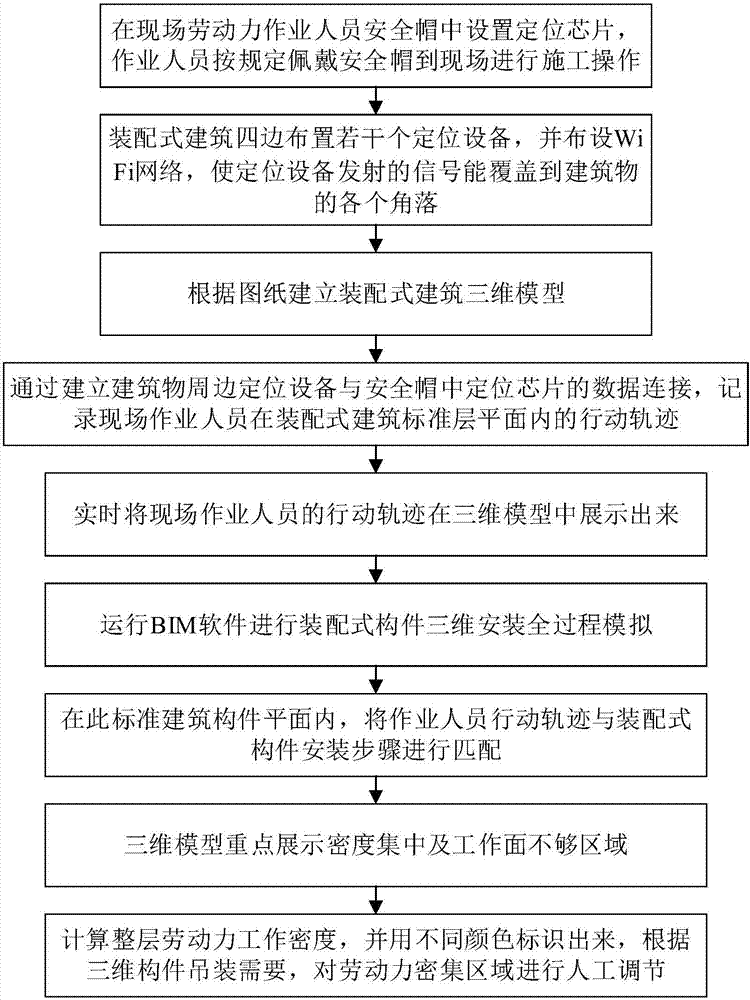

[0026] Such as figure 1 As shown, the present invention provides a BIM-based engineering material stacking method, which specifically includes

[0027] Step 1. Set the positioning chip in the safety helmet of the on-site labor workers, and the workers will wear the safety helmet to the site for construction operations as required;

[0028] Step 2. Several positioning devices are arranged on the four sides of the prefabricated building, and Wi-Fi networks are deployed so that the signals emitted by the positioning devices can cover all corners of the building;

[0029] Step 3. Establish a three-dimensional model of the prefabricated building according to the drawings;

[0030] Step 4. By establishing a data connection between the surrounding positioning equipment of the building and the positioning chip in the helmet, record the movement track of the field operator in the standard floor plane of the prefabricated building;

[0031] Step 5. Real-time display the trajectory of on-site ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com