Manufacturing method of fireproof cable for multifunctional rail transit

A rail transit and fireproof cable technology, applied in cable/conductor manufacturing, insulated cables, cables, etc., can solve problems such as few entrances and exits, accidents, and complex on-site environments, and achieve excellent high-temperature insulation performance, enhanced fireproof performance, and good durability. The effect of high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

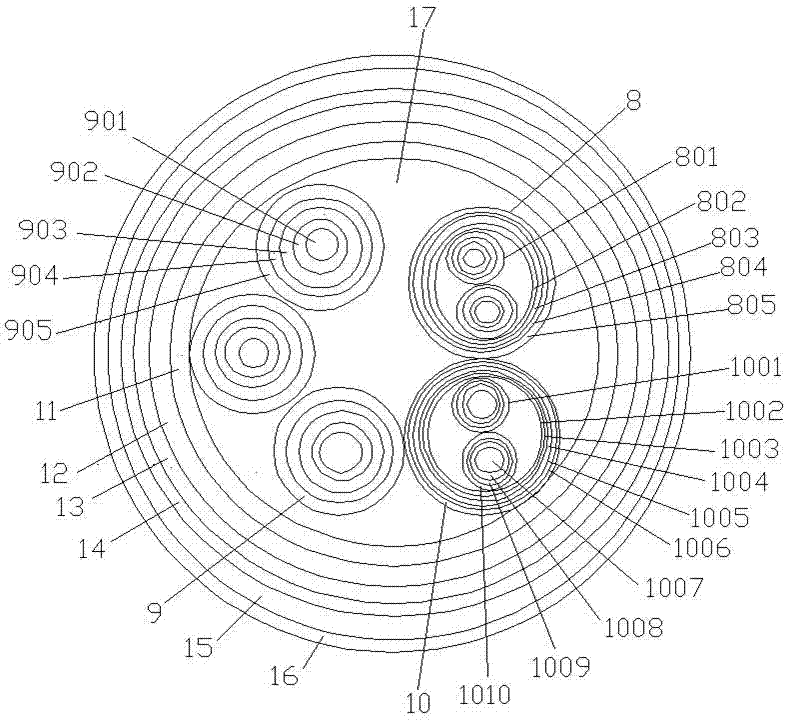

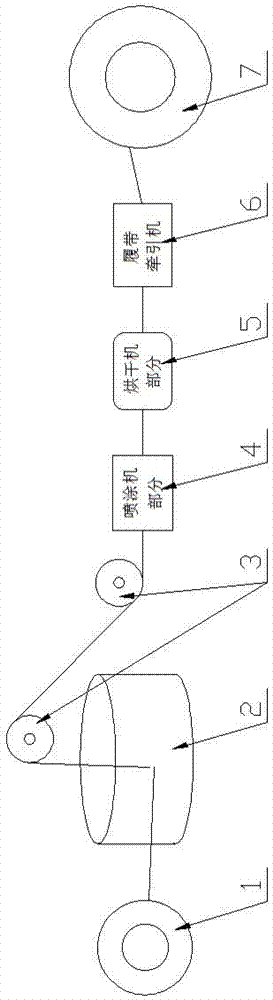

[0043] Attached below Figure 1-2 , a method for manufacturing a multifunctional rail transit fireproof cable of the present invention is described in detail below.

[0044] as attached figure 1 As shown, a multi-functional fireproof cable for rail transit of the present invention includes: a cable core and an outer shell surrounding the cable core, and the cable core is made of single or composite functional cables. The key point is that each functional cable and / or housing at least includes an alkali-free ceramic fiber yarn braiding layer and a high-temperature-resistant nano-coating on the outer surface of the alkali-free ceramic fiber yarn braiding layer, and the high-temperature-resistant nano-coating The high temperature range of the layer is 500-1500°C. It should be noted that in the case of different heat resistance requirements, only the technical scheme of weaving the alkali-free ceramic fiber yarn braided layer or spraying with high-temperature resistant nano-coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com