Battery necking machine

A battery and shrinking technology, applied in the manufacturing of primary batteries, secondary batteries, circuits, etc., can solve the problems of no shrinking equipment for remedial work, unreasonable sealing equipment design, insufficient battery sealing pressure, etc., to increase the burst pressure and Charge and discharge performance, improved usability, reduced shoulder height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

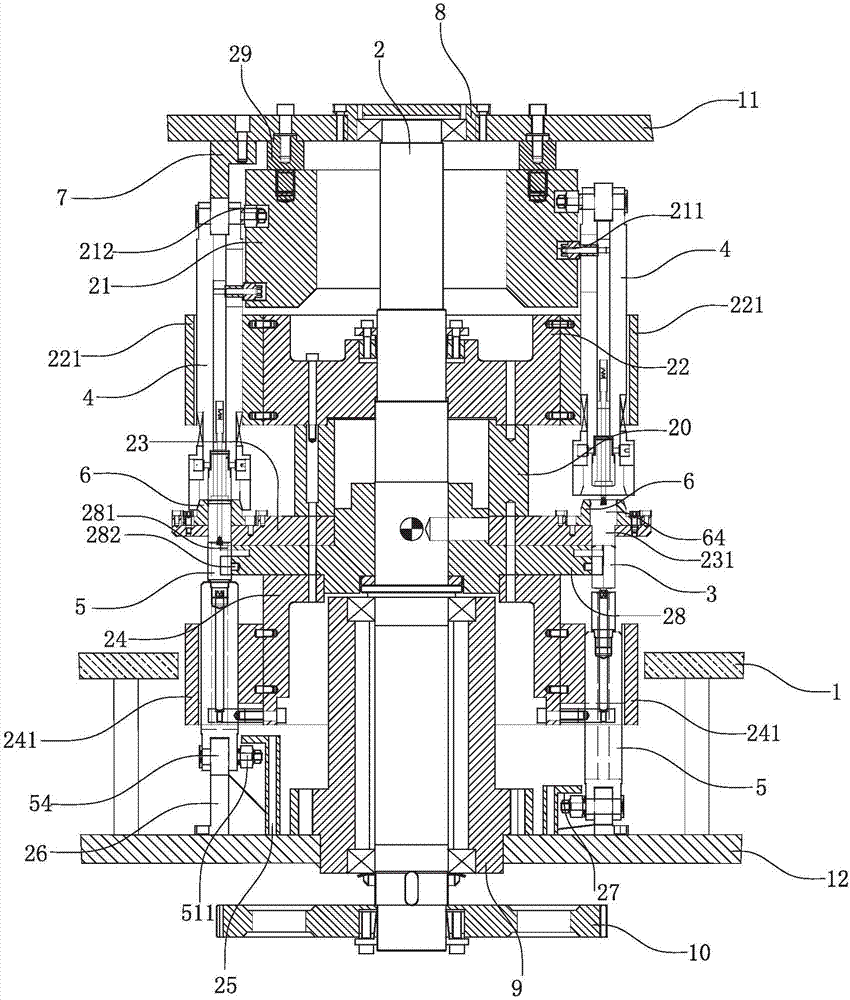

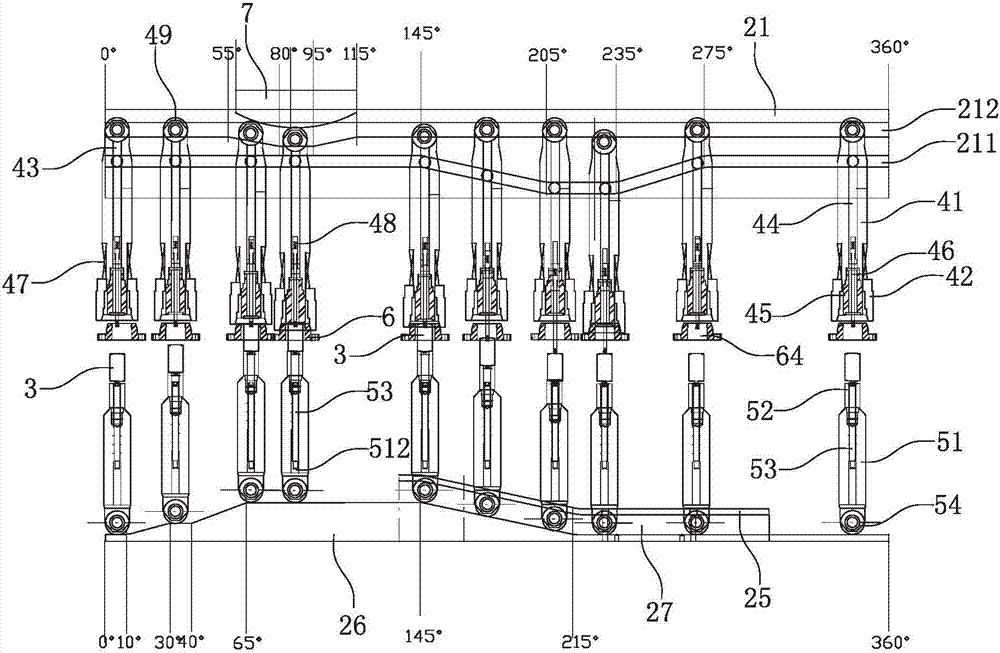

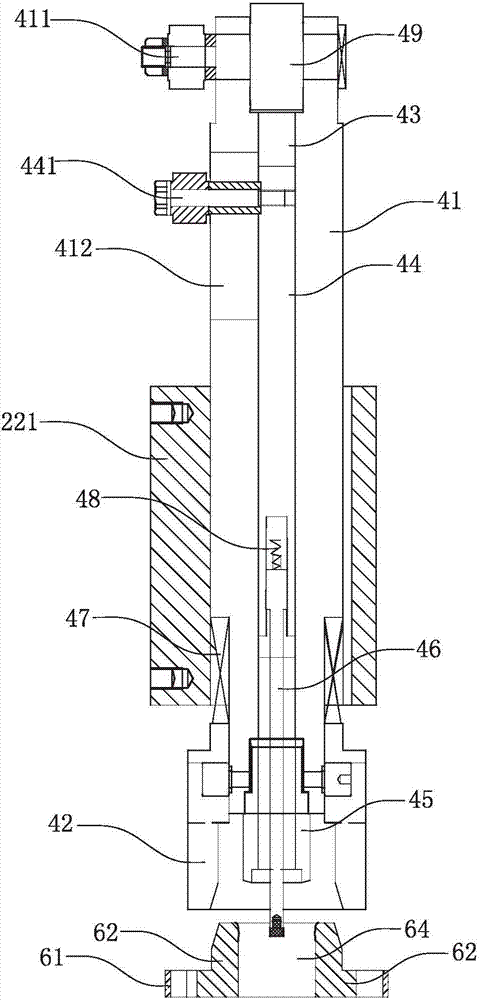

[0027] Such as Figure 1-6 As shown, the embodiment of the present invention provides a battery shrinking machine, including a frame 1, a rotating shaft 2 arranged on the frame 1 is rotated vertically, and a drive assembly (not shown) for driving the rotating shaft 2 to rotate The rotating shaft 2 is provided with a depression bar lifting cam 21, a depression bar rotating wheel 22, a rotating disk 23, a pushing rod rotating wheel 24 and a lower cam 26 for lifting the pushing rod in turn on the rotating shaft 2. The rod lift guide surface 25, the push rod lift cam 21, the push rod lift guide surface 25 and the push rod lift lower cam 26 are respectively fixed with the frame 1, the push rod rotating wheel 22, the turntable 23, the push rod rotating wheel 24 are fixed with the rotating shaft 2 And rotate with the rotating shaft 2 in the same dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com