Programmable analog heating apparatus used for battery thermal management test and control method for programmable analog heating apparatus

A battery thermal management and heating device technology, applied in secondary battery testing, secondary batteries, electrochemical generators, etc., can solve problems such as poor repeatability and controllability, loss of battery pack capacity, and difficulty in simulating fault states. Achieve the effect of good repeatability and convenient testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

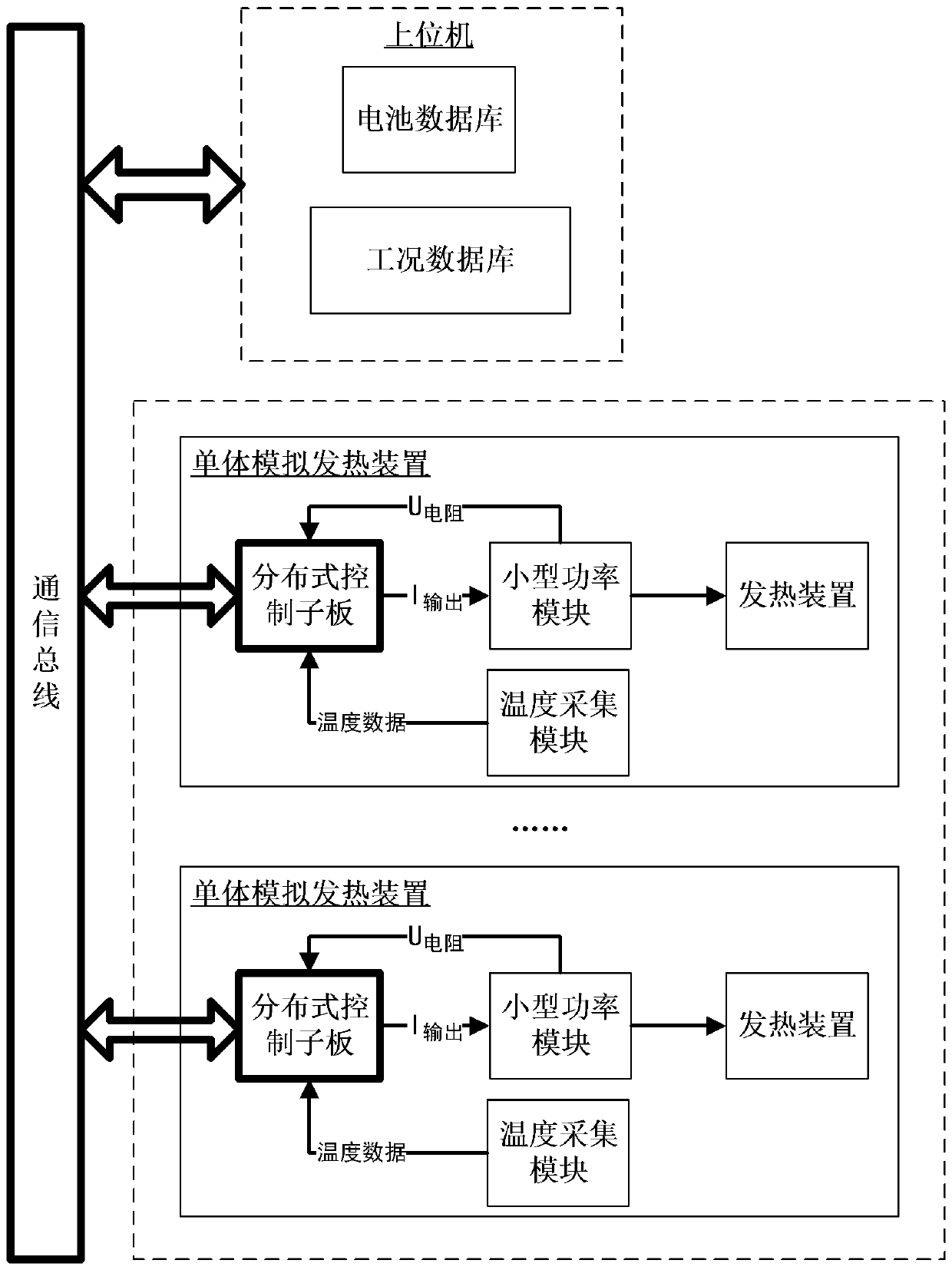

[0017] refer to Figure 1 to Figure 4 , the simulated battery heating device includes three parts: a host computer, a communication bus and a simulated heating device system.

[0018] The upper computer of the present invention is mainly used for functions such as initialization of heating model parameters, issuance of test commands, online control of distributed sub-boards, storage and display of test data; the upper computer and other hardware parts of the system are mainly connected through the CAN communication module. Wherein, the upper computer of the present invention is a personal computer or an embedded system. The communication interface module of the present invention mainly plays the role of bridging, that is, realizes two-way communication between the CAN communication bus composed of the CAN communication bus and the control sub-board of the analog heating device and the host computer.

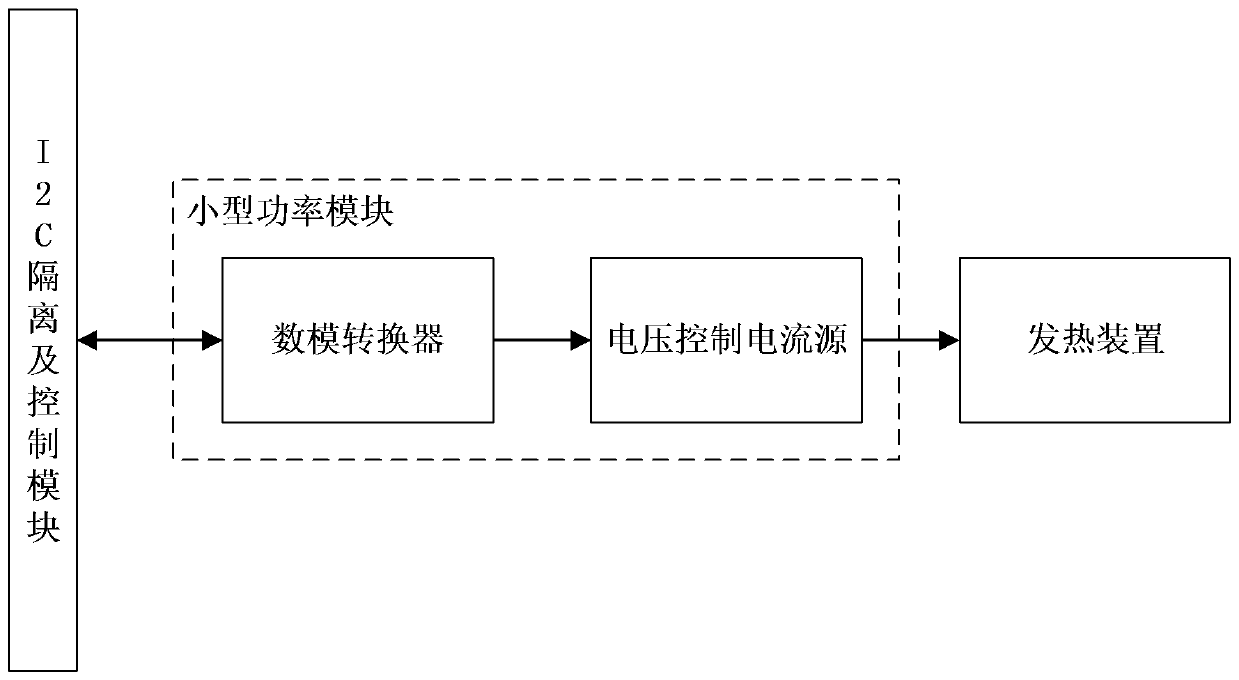

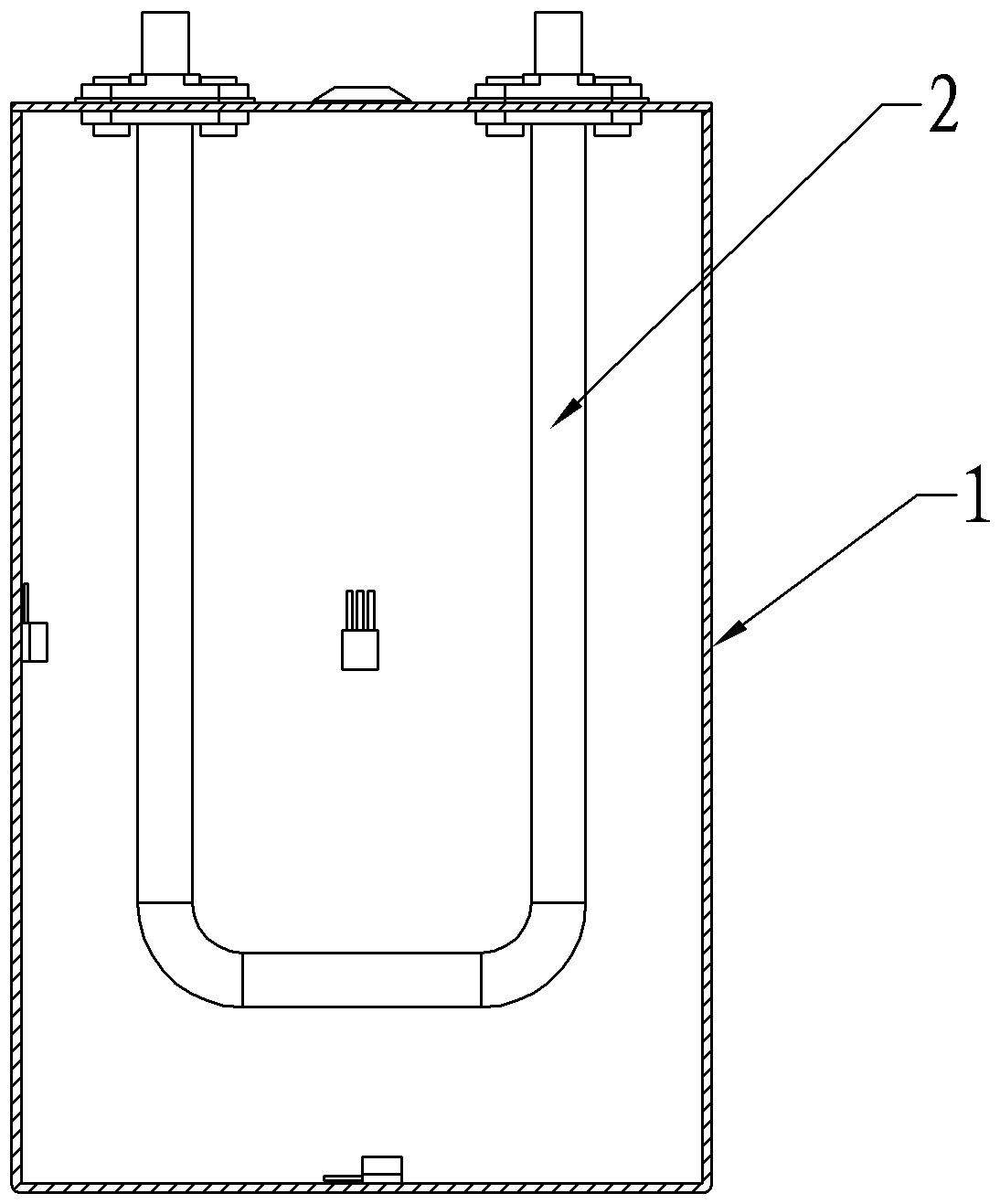

[0019] The simulated heating device of the present invention is composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com