Motor drive circuit system

A motor drive and circuit technology, applied in emergency protection circuit devices, electrical components, electric steering mechanisms, etc., can solve the problems that the buffer circuit cannot handle sudden changes in current, catastrophic failure, SSPIR damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

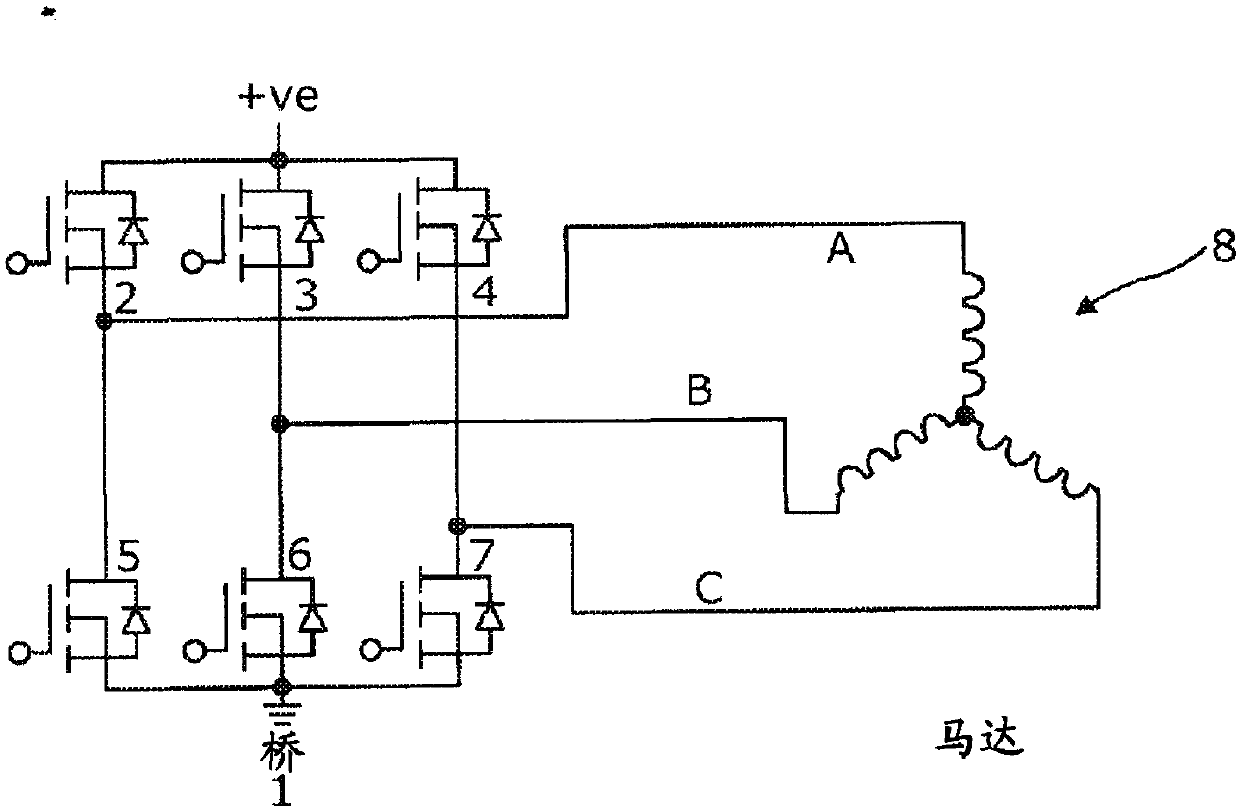

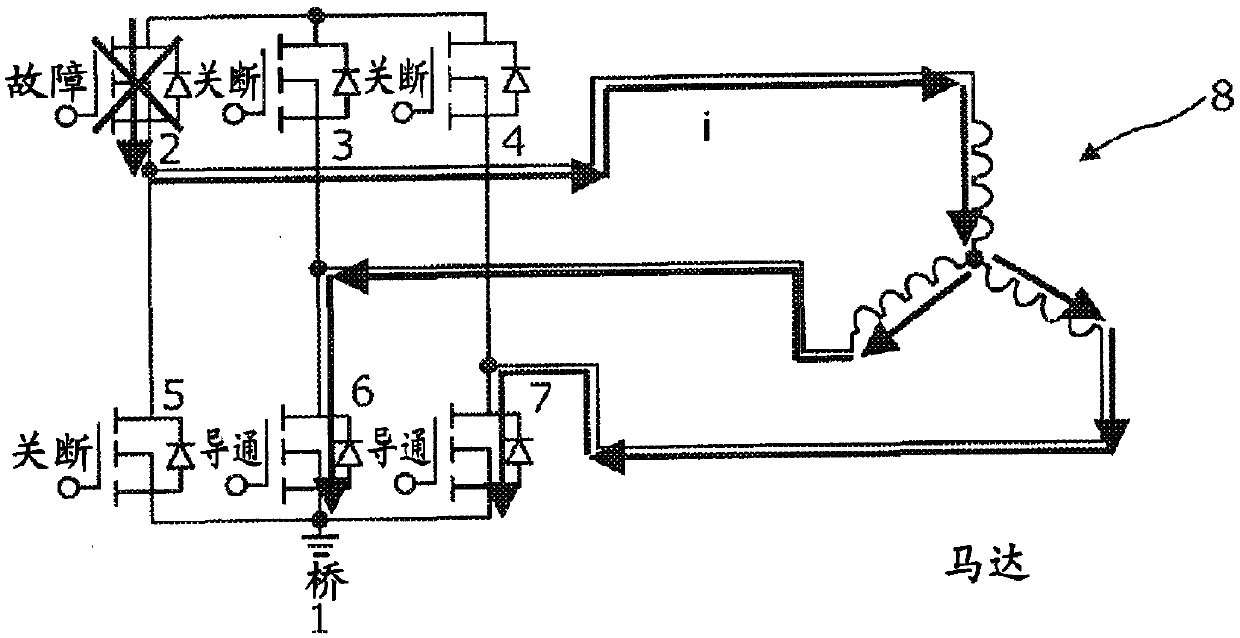

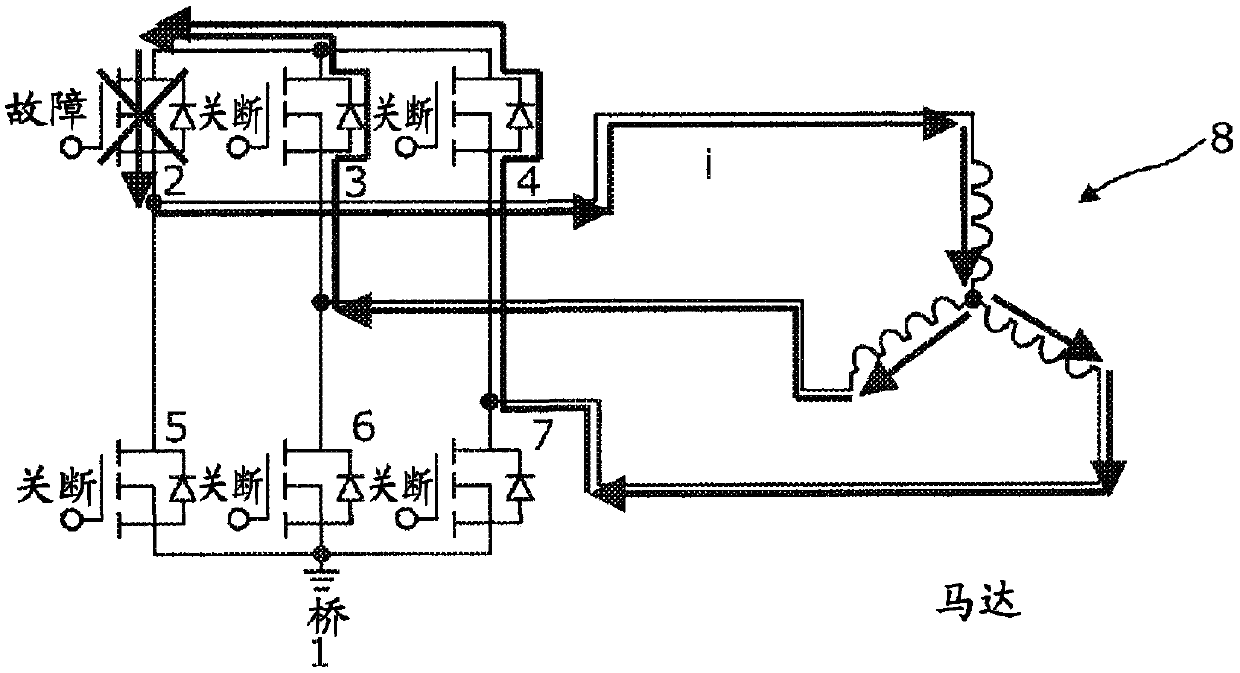

[0092] Such as Figure 7 As shown in , a motor drive circuit 100 for an electric power steering system is shown. Motor 101 comprises a three-phase motor having three phases U, V and W connected together at a common star point 102 . The end of each phase not connected at the star point is connected to a corresponding branch of the motor bridge circuit 103 via a plurality of solid state phase isolated relays (SSPIRs) 104, 105, 106, with each SSPIR being in series with each phase. The schematic shows the internal diode and Miller capacitance (associated with the MOSFET device) as separate elements for each SSPIR.

[0093] The motor bridge circuit is not shown in detail, but typically with figure 1 Consistent with that shown in . Each arm or branch includes an upper portion connecting the motor phase to the positive side of the battery power supply through a top MOSFET switch, and a lower portion connecting the motor phase to the negative side of the battery power supply throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com