Ignition system and method for checking electrodes of a spark plug in an internal combustion engine

A technology of ignition system and internal combustion engine, applied in the field of ignition system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

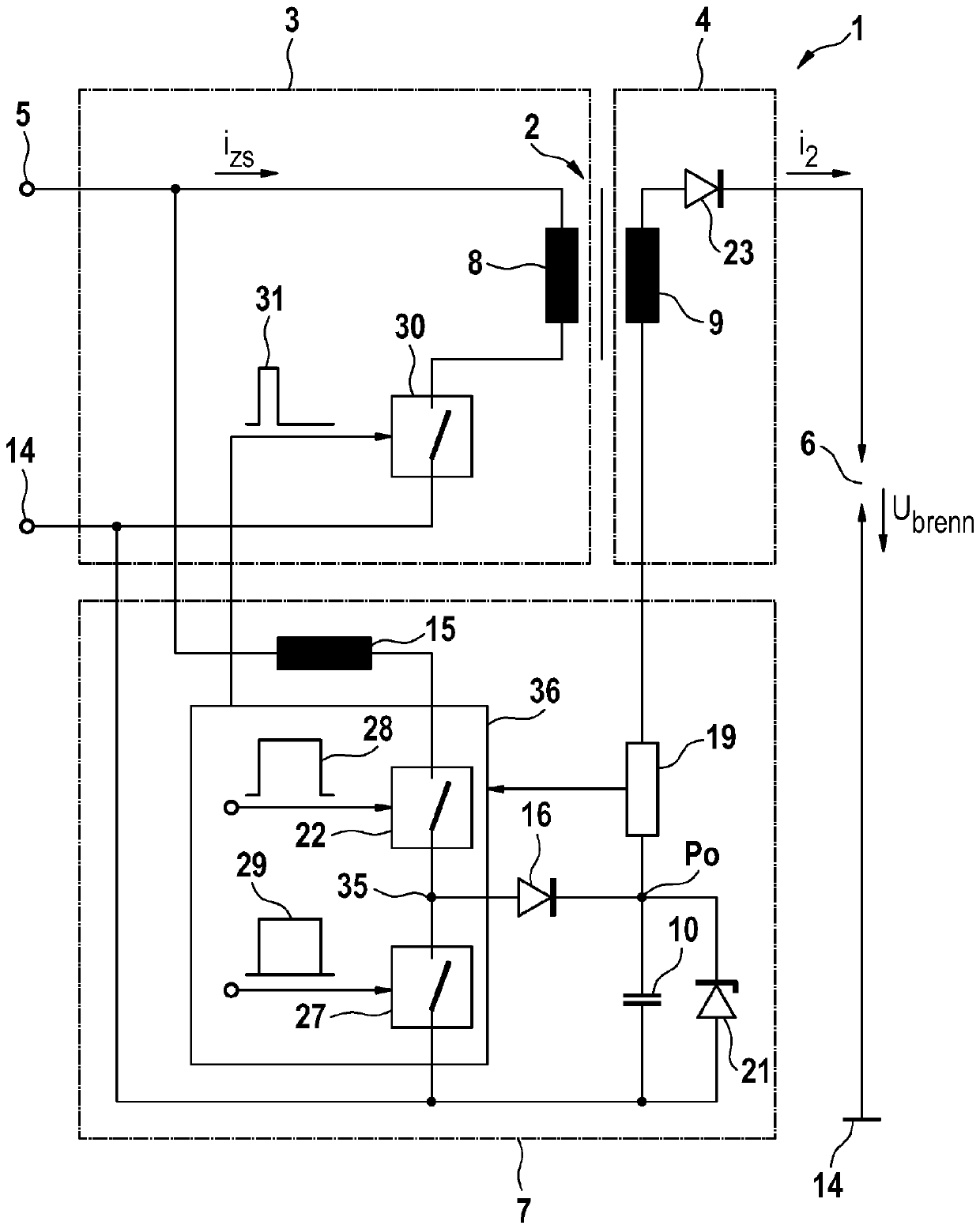

[0028] figure 1 The electrical circuit of an ignition system 1 is shown, which comprises a step-up transformer 2 as a high-voltage generator, the primary 3 of which can be supplied with electrical energy from an electrical energy source 5 via a first switch 30 . The secondary 4 of the step-up transformer 2 is supplied with electrical energy via the inductive coupling of the primary coil 8 and the secondary coil 9 and has a diode 23 known from the prior art for suppressing switch-on sparks, this diode 23 being optional Replaced by diode 21. In the mesh with secondary coil 9 and diode 23 is provided with spark gap 6 of ground wire 14, ignition current i 2 The combustible air-fuel mixture is to be ignited via this spark gap. The spark ignition voltage U, which usually fluctuates when the ignition is complete, is applied at the spark gap 6 brenn . According to the invention, a step-up converter 7 is arranged between the electrical energy source 5 and the secondary 4 of the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com