Coil component

A coil component and coil technology, which is applied in coil manufacturing, transformer/inductor parts, electrical components, etc., can solve the problems of reducing the number of turns of coil electrodes 102 and limited space, and achieve the effect of improving heat dissipation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

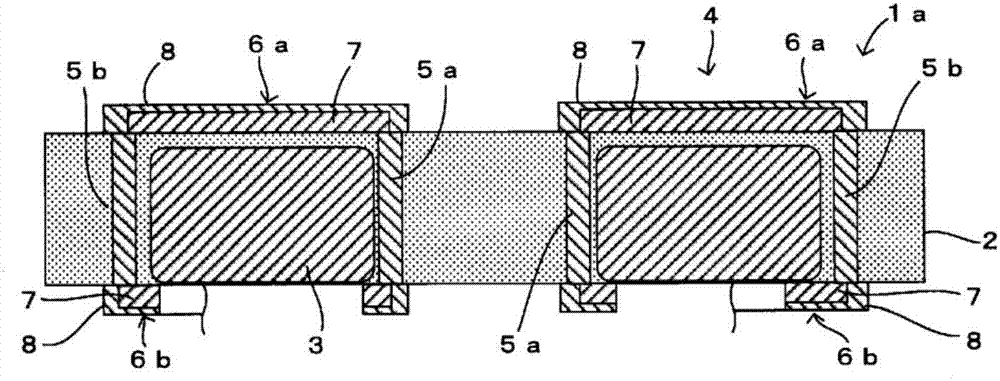

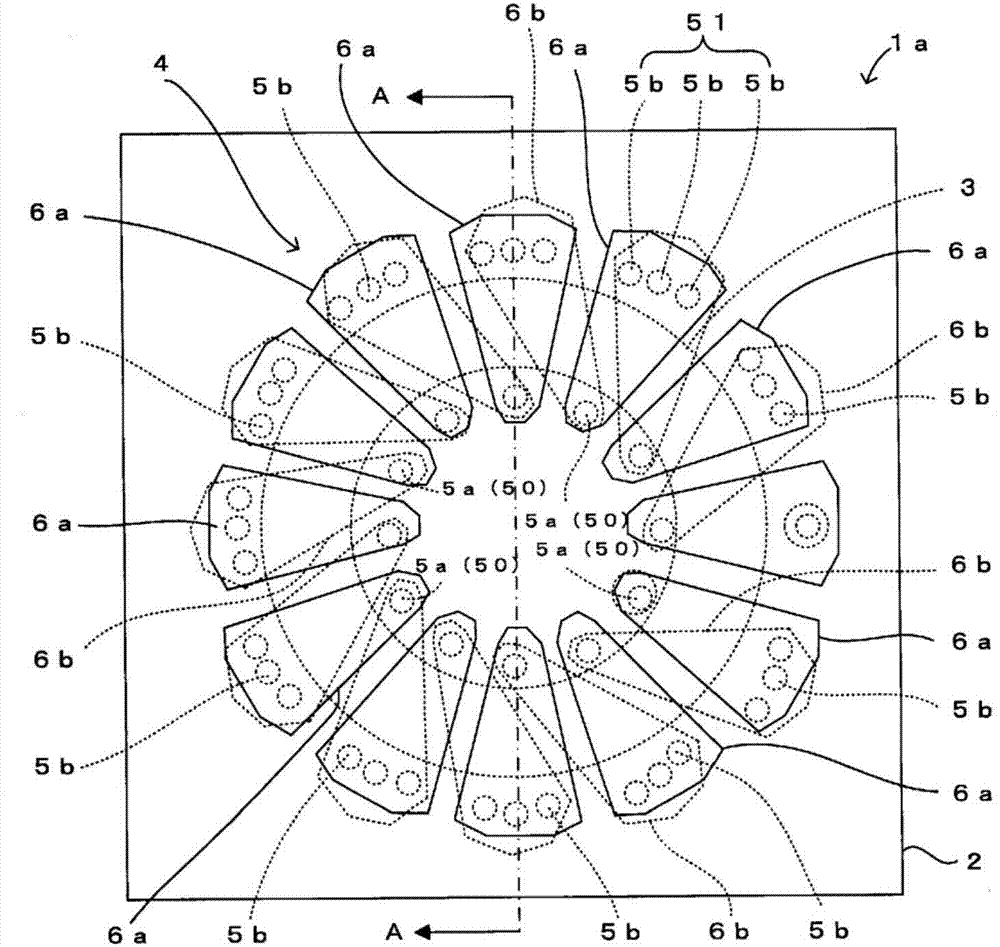

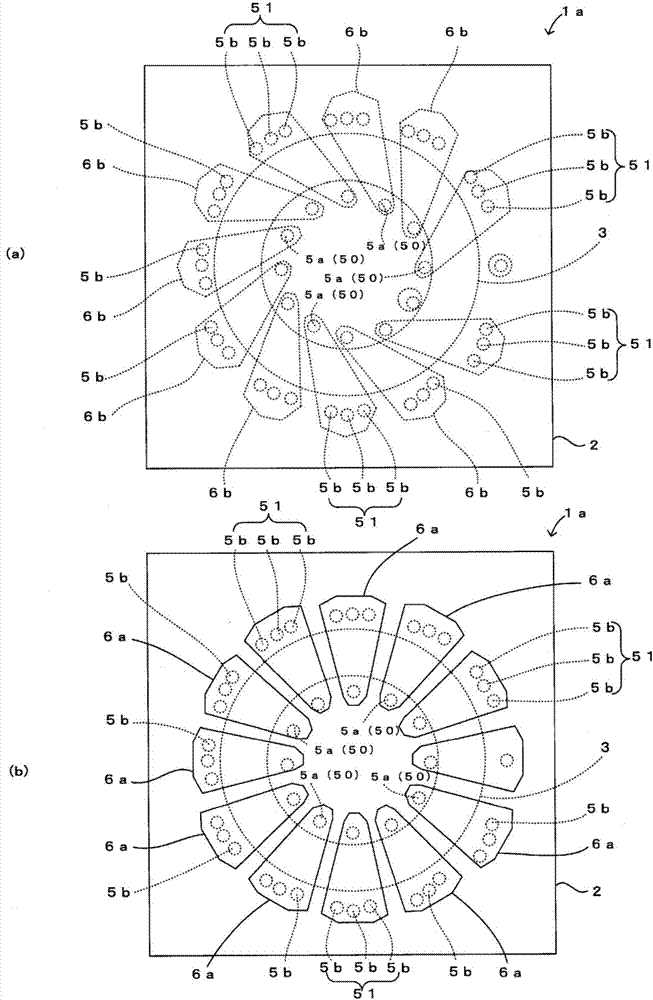

[0030] refer to Figure 1 ~ Figure 3 The coil component 1a according to the first embodiment of the present invention will be described. in, figure 1 is a sectional view of the coil component 1a, figure 2 is a plan view of the coil component 1a, image 3 It is a figure for demonstrating wiring pattern 6a, 6b. in addition, image 3 (a) is a plan view of the coil component 1a in a state where the upper wiring pattern 6a is removed, image 3 (b) is a plan view of the coil component 1a in a state where the lower wiring pattern 6b is removed. also, figure 1 Yes figure 2 A cross-sectional view in the direction of the arrow A-A. In addition, in image 3 In (a), the wiring for input and output connected to the end part of the coil electrode 4 is abbreviate|omitted.

[0031] like Figure 1 ~ Figure 3 As shown, the coil component 1a according to this embodiment includes an insulating layer 2 in which a coil core 3 is embedded, and a coil electrode 4 wound around the coil ...

no. 2 approach >

[0058] refer to Figure 4 The coil component 1b according to the second embodiment of the present invention will be described. In addition, this figure is a plan view of the coil component 1b in a state in which the lower wiring pattern 6b is removed, and is the same as image 3 (b) Corresponding figure.

[0059] like Figure 4 As shown, the coil component 1b related to this embodiment is the same as the reference Figure 1 ~ Figure 3 The coil component 1a of the first embodiment described is different in that the number of outer metal pins 5b constituting each outer conductor 51 is different, and the outer metal pins 5b are formed to be smaller than the inner metal pins 5a (excluding the metal pins for external connection). outside) rough. The other configurations are the same as those of the coil component 1a of the first embodiment, so the same reference numerals are assigned and descriptions thereof are omitted.

[0060] In this case, each outer conductor 51 is compos...

no. 3 approach >

[0063] refer to Figure 5A coil component 1c according to a third embodiment of the present invention will be described. In addition, this figure shows the plan view of the coil component 1c in the state which removed the lower wiring pattern 6b, and is the same as image 3 (b) Corresponding figure.

[0064] like Figure 5 As shown, the coil component 1c related to this embodiment is the same as the reference Figure 1 ~ Figure 3 The coil component 1a of the first embodiment described is different in that each inner metal needle 5a is formed thicker than each outer metal needle 5b. The other configurations are the same as those of the coil component 1a of the first embodiment, so the same reference numerals are assigned and descriptions thereof are omitted.

[0065] In this case, each outer metal needle 5b is formed with the same thickness and length, and each inner metal needle 5a is also formed with the same thickness and length. Also, each inner metal needle 5a is form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com