Manufacture method of cured purple sweet potato powder ice cream

A production method and technology of ice cream, applied in frozen sweets, food ingredients as taste improvers, food science, etc., to achieve the effects of improving expansion rate and melting resistance, saving energy, and improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

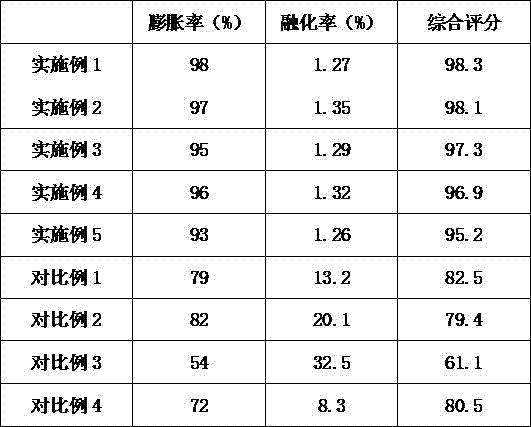

Examples

Embodiment 1

[0026] A method for making purple sweet potato cooked powder ice cream includes the following steps:

[0027] A. Washing, peeling, shredding, pre-cooking, color-protecting, drying and crushing the purple potato raw materials to obtain the purple potato cooked powder;

[0028] B. Mix white granulated sugar, milk powder and water to obtain frozen slurry after freezing;

[0029] C. Mix the purple sweet potato cooked powder, high-gel egg protein powder and jelly slurry, and conduct homogenization and aging treatment;

[0030] D. Quickly freeze and harden at -18℃, and put it into an ice cream machine to make ice cream.

[0031] The particle size of the purple sweet potato cooked powder ≤ 1mm.

[0032] In the step A, after drying and cooling, the moisture content of the cooked purple potato flour is controlled at 2.5%.

[0033] In the step C, the high-gelatin egg protein powder is an ultra-high gel degree and high-gel egg protein powder with a gel strength exceeding 1000.

[0034] In the step B,...

Embodiment 2

[0037] A method for making purple sweet potato cooked powder ice cream includes the following steps:

[0038] A. Washing, peeling, shredding, pre-cooking, color-protecting, drying and crushing the purple potato raw materials to obtain the purple potato cooked powder;

[0039] B. Mix white granulated sugar, milk powder and water to obtain frozen slurry after freezing;

[0040] C. Mix the purple potato cooked powder, high-gel egg protein powder and jelly slurry, and conduct homogenization and aging treatment;

[0041] D. Quickly freeze and harden at -12℃, and put it into an ice cream machine to make ice cream.

[0042] The particle size of the purple sweet potato cooked powder ≤ 1mm.

[0043] In the step A, after drying and cooling, the moisture content of the cooked purple potato flour is controlled at 2%.

[0044] In the step C, the high-gelatin egg protein powder is an ultra-high gel degree and high-gel egg protein powder with a gel strength exceeding 1000.

[0045] In said step B, the ma...

Embodiment 3

[0048] A method for making purple sweet potato cooked powder ice cream includes the following steps:

[0049] A. Washing, peeling, shredding, pre-cooking, color-protecting, drying and crushing the purple potato raw materials to obtain the purple potato cooked powder;

[0050] B. Mix white granulated sugar, milk powder and water to obtain frozen slurry after freezing;

[0051] C. Mix the purple potato cooked powder, high-gel egg protein powder and jelly slurry, and conduct homogenization and aging treatment;

[0052] D. Quickly freeze and harden at -10℃, and put it into an ice cream machine to make ice cream.

[0053] The particle size of the purple sweet potato cooked powder ≤ 1mm.

[0054] In the step A, after drying and cooling, the moisture content of the cooked purple potato flour is controlled at 4%.

[0055] In the step C, the high gel egg protein powder is an ultra-high gel degree high gel egg protein powder with a gel strength exceeding 1000.

[0056] In the step B, the mass ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com