Silage and feed with silage

A technology of silage and feed, applied in the field of feed with the silage, can solve the problems of stale odor, black color, high labor intensity, etc., achieve a slight sour aroma and fruity taste, reduce buffer capacity, and ensure sugar content volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

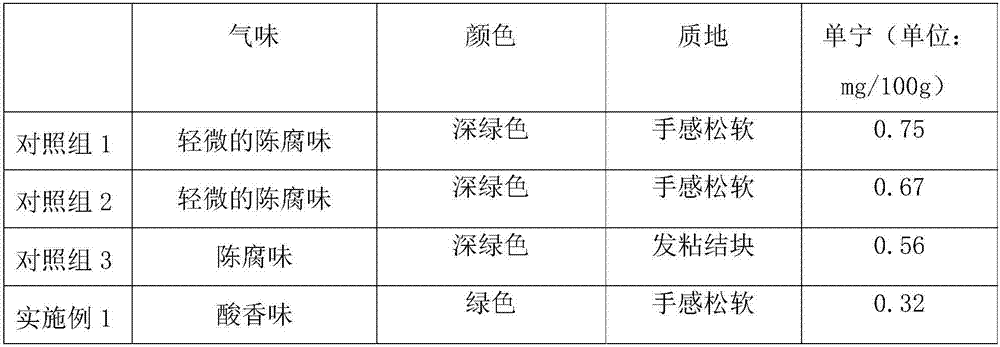

Examples

Embodiment 1

[0021] A kind of silage, the silage includes banana stems and leaves and stalks, wherein the preparation method of the silage is as follows:

[0022] ① Collect the banana stems and leaves, and slice the banana stems and leaves;

[0023] ② Cut the banana stems into slices with a thickness of 1-4cm;

[0024] ③Prepare the fermented liquid, which mainly consists of the following percentages of raw materials: 0.2% of salt, 0.2% of distiller’s yeast, 0.2% of urea, 0.2% of potassium fertilizer, 0.2% of phosphate fertilizer, 0.01% of ripening agent, 0.2% of EM bacteria, and 0.2% of turmeric , bagasse 10%, amino acid 0.2%, ginger 0.2%, tiger thorn 5%, tea dregs 10% by adding water 73.19%, and the fermented liquid is sprayed on the banana stems and leaves treated in steps ① and ②. Turn over the banana stems and leaves while spraying, so that the banana stems and leaves can fully absorb the fermentation liquid;

[0025] ④ Cut the dried straw to 5-6cm;

[0026] ⑤Put 10-12cm thick straw...

Embodiment 2

[0028] A kind of silage, the silage includes banana stems and leaves and stalks, wherein the preparation method of the silage is as follows:

[0029] ① Collect the banana stems and leaves, and slice the banana stems and leaves;

[0030] ② Cut the banana stems into slices with a thickness of 1-4cm;

[0031] ③Prepare the fermented liquid, which mainly consists of the following percentages of raw materials: 0.3% of salt, 0.3% of distiller’s yeast, 0.3% of urea, 0.3% of potassium fertilizer, 0.3% of phosphate fertilizer, 0.01% of ripening agent, 0.3% of EM bacteria, and 0.3% of turmeric , bagasse 12%, amino acid 0.3%, ginger 0.3%, tiger thorn 7%, tea dregs 12% by adding water 66.29%, and the fermented liquid is sprayed on the banana stems and leaves treated in steps ① and ②, and the Turn over the banana stems and leaves while spraying, so that the banana stems and leaves can fully absorb the fermentation liquid;

[0032] ④ Cut the dried straw to 5-6cm;

[0033] ⑤Put 10-12cm thi...

Embodiment 3

[0035] A kind of silage, the silage includes banana stems and leaves and stalks, wherein the preparation method of the silage is as follows:

[0036] ① Collect the banana stems and leaves, and slice the banana stems and leaves;

[0037] ② Cut the banana stems into slices with a thickness of 1-4cm;

[0038] ③Prepare the fermented liquid, which mainly consists of the following percentages of raw materials: 0.4% of salt, 0.4% of distiller’s yeast, 0.4% of urea, 0.4% of potassium fertilizer, 0.4% of phosphate fertilizer, 0.01% of ripening agent, 0.4% of EM bacteria, and 0.4% of turmeric , bagasse 15%, amino acid 0.4%, ginger 0.4%, tiger thorn 9%, tea dregs 15% by adding water 57.39%, and the fermented liquid is sprayed onto the banana stems and leaves treated in steps ① and ②. Turn over the banana stems and leaves while spraying, so that the banana stems and leaves can fully absorb the fermentation liquid;

[0039] ④ Cut the dried straw to 5-6cm;

[0040] ⑤Put 10-12cm thick str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com