Constant-temperature hydraulic station

A hydraulic station and constant temperature technology, which is applied in the field of hydraulic systems, can solve problems such as accelerated mechanical wear, accelerated oil quality deterioration, and reduced efficiency, and achieves the effects of stabilizing power performance, prolonging service life, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

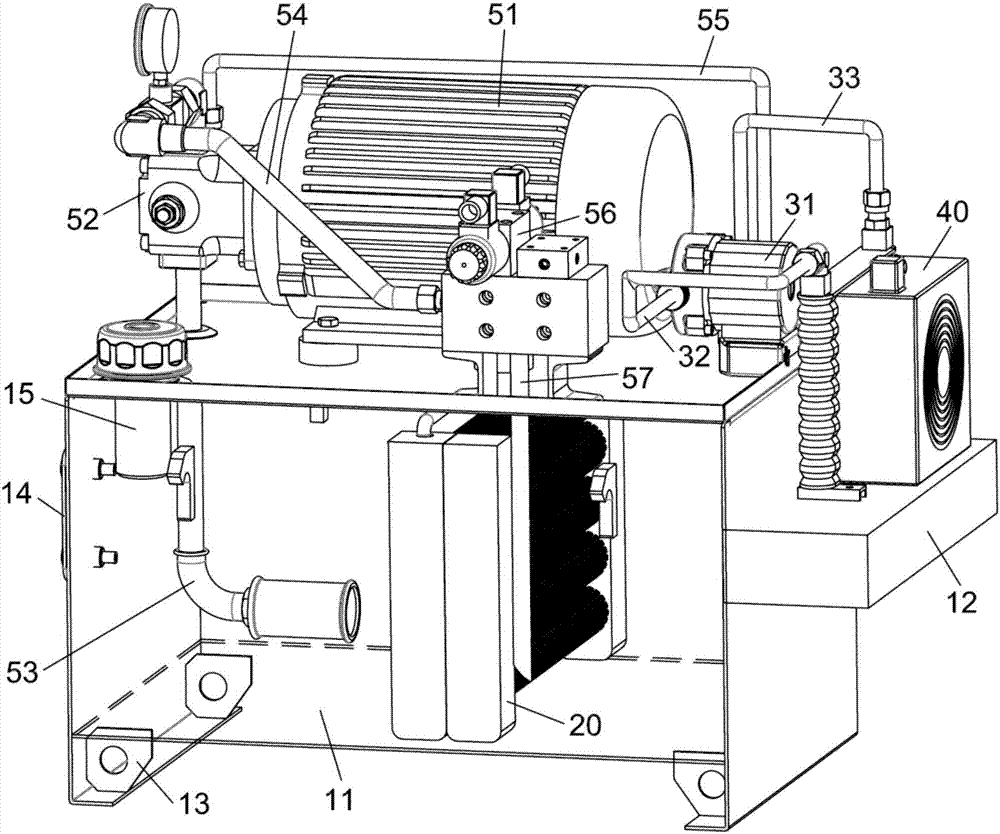

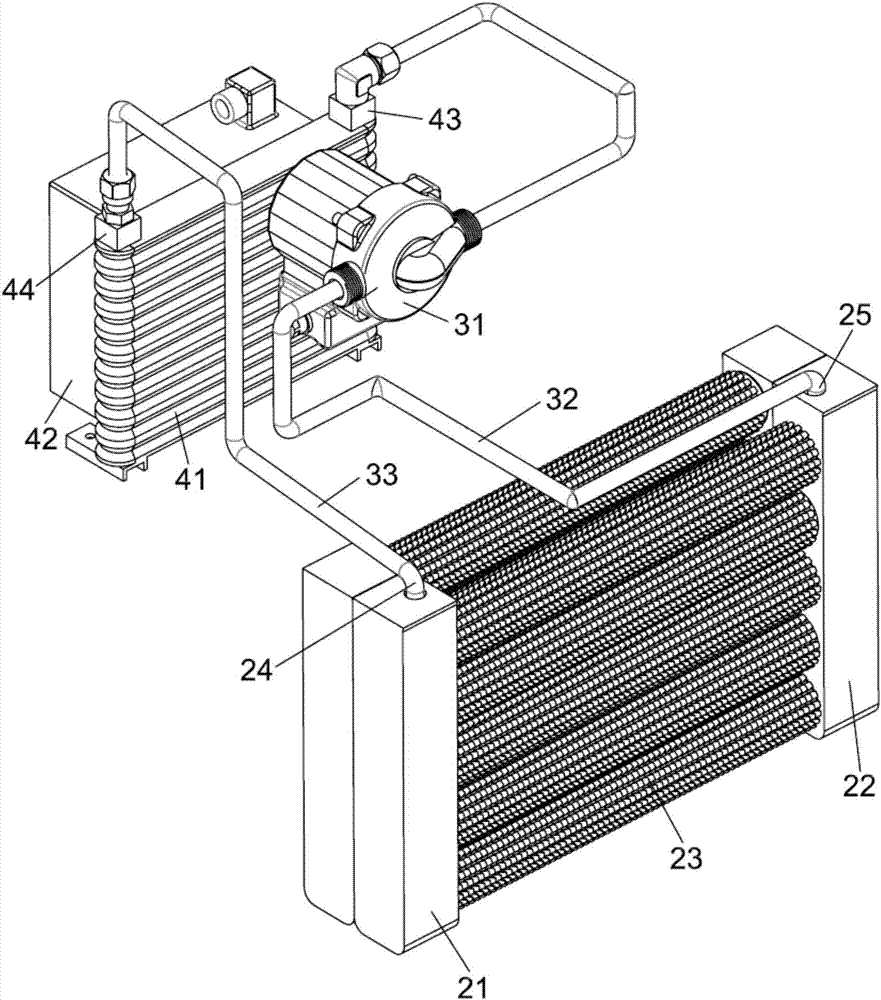

[0019] Refer to attached figure 1 And attached figure 2 , the present invention provides a constant temperature hydraulic station, including a fuel tank 11 and a cooling assembly filled with antifreeze, the cooling assembly includes a finned radiator 20, a cooling pump 31 and an air cooler 40, the finned radiator 20 is arranged in the middle of the oil tank 11, The cooling pump 31 and the air cooler 40 are provided outside the oil tank 11 .

[0020] The air cooler 40 includes an annular water chamber 41 and a fan 42. The annular water chamber 41 is arranged behind the fan 42. A water chamber water inlet 43 is arranged on one side of the annular water chamber 41, and a water chamber water outlet 44 is arranged on the other side.

[0021] The fin radiator 20 comprises a first bracket 21 and a second bracket 22 and a plurality of finned heat pipes 23, the finned heat pipes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com