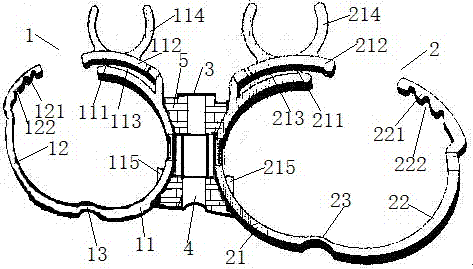

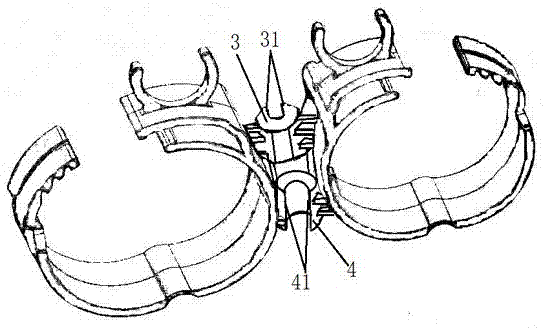

Fixing fastener of central air conditioning condenser pipe and production technology of fixing fastener

A technology for fixing clips and central air conditioning, applied in the direction of pipes/pipe joints/fittings, pipe supports, space heating and ventilation details, etc. The effect of beautiful appearance, few parts and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The plastic material of the first buckle 1, the second buckle 2 and the connection structure includes the following components in parts by weight: polyethylene PE 40 parts, polypropylene PP 20 parts, polyhydroxyalkanoate 10 parts, thermoplastic polyurethane 10 parts , 5 parts of polybutylene succinate, 1 part of anti-aging agent, 1 part of antistatic agent, 3 parts of toner.

[0036] The production process of the central air-conditioning condensation pipe fixing buckle described in this embodiment:

[0037] 1) Mix and granulate 40 parts of polyethylene PE, 20 parts of polypropylene PP, 10 parts of polyhydroxyalkanoate, 10 parts of thermoplastic polyurethane, and 5 parts of polybutylene succinate, then crush them with a pulverizer and pass through 60 meshes Sieve, re-grind those that do not pass through the 60-mesh sieve until all pass through the 60-mesh sieve;

[0038] 2) Put the crushed plastic particles in step 1) into the mixer, and add 1 part of anti-aging agent, ...

Embodiment 2

[0042] The plastic material of the first buckle 1, the second buckle 2 and the connection structure includes the following components by weight: 50 parts of polyethylene PE, 30 parts of polypropylene PP, 20 parts of polyhydroxyalkanoate, 20 parts of thermoplastic polyurethane , 15 parts of polybutylene succinate, 3 parts of anti-aging agent, 3 parts of antistatic agent, 5 parts of toner.

[0043] The production process of the central air-conditioning condensation pipe fixing buckle described in this embodiment:

[0044] 1) Mix and granulate 50 parts of polyethylene PE, 30 parts of polypropylene PP, 20 parts of polyhydroxyalkanoate, 20 parts of thermoplastic polyurethane, and 15 parts of polybutylene succinate, then crush them with a pulverizer and pass through 60 meshes Sieve, re-grind those that do not pass through the 60-mesh sieve until all pass through the 60-mesh sieve;

[0045] 2) Put the crushed plastic particles in step 1) into the mixer, and add 3 parts of anti-aging...

Embodiment 3

[0049] The plastic materials of the first buckle 1, the second buckle 2 and the connection structure include the following components by weight: polyethylene PE 45 parts, polypropylene PP 25 parts, polyhydroxyalkanoate 15 parts, thermoplastic polyurethane 15 parts , 10 parts of polybutylene succinate, 2 parts of anti-aging agent, 2 parts of antistatic agent, 4 parts of toner.

[0050] The production process of the central air-conditioning condensation pipe fixing buckle described in this embodiment:

[0051] 1) Mix and granulate 45 parts of polyethylene PE, 25 parts of polypropylene PP, 15 parts of polyhydroxyalkanoate, 15 parts of thermoplastic polyurethane, and 10 parts of polybutylene succinate, then crush them with a pulverizer and pass through 60 meshes Sieve, re-grind those that do not pass through the 60-mesh sieve until all pass through the 60-mesh sieve;

[0052] 2) Put the crushed plastic particles in step 1) into the mixer, and add 2 parts of anti-aging agent, 2 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com