DSP-based comparison-division type optical fiber high-precision frequency measurement sensor

A high-precision, sensor technology, used in linear/angular velocity measurement, velocity/acceleration/shock measurement, instruments, etc., to solve problems such as unstable light source power, inability to achieve high-precision micro-frequency measurement, and inability to fully respond to optical fiber signals. , to achieve accurate and reliable frequency measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below by specific embodiments:

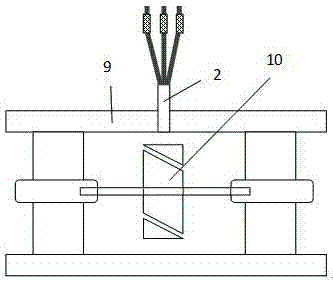

[0019] The reference signs in the accompanying drawings include: laser light source 1, fiber probe 2, preprocessing circuit 3, DSP chip 4, host computer 5, transmitting fiber 6, first group of receiving fibers 7, second group of receiving fibers 8, Rotor top casing 9 and rotor blades 10 to be tested.

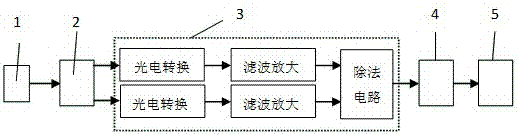

[0020] like figure 1 The shown one DSP-based ratio-division fiber-optic high-precision frequency measurement sensor includes: a laser light source 1 that emits laser light to a fiber-optic probe 2;

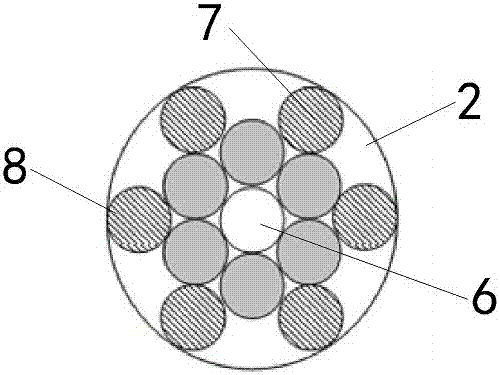

[0021] Fiber probe 2, such as figure 2 As shown, it includes a transmitting optical fiber 6 and two groups of receiving optical fibers, each group contains six optical fibers, the first group of receiving optical fibers 7 is distributed on the outside of the transmitting optical fiber 6, and the second group of receiving optical fibers 8 is distributed in the first group of receiving opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com