Laser-activated vanadate composite crystal with ion doping concentration gradient and preparation method thereof

A gradient vanadate, composite crystal technology, applied in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve the problems of uncontrollable growth process of liquid phase epitaxy, a large number of bubbles and inclusions, and laser loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

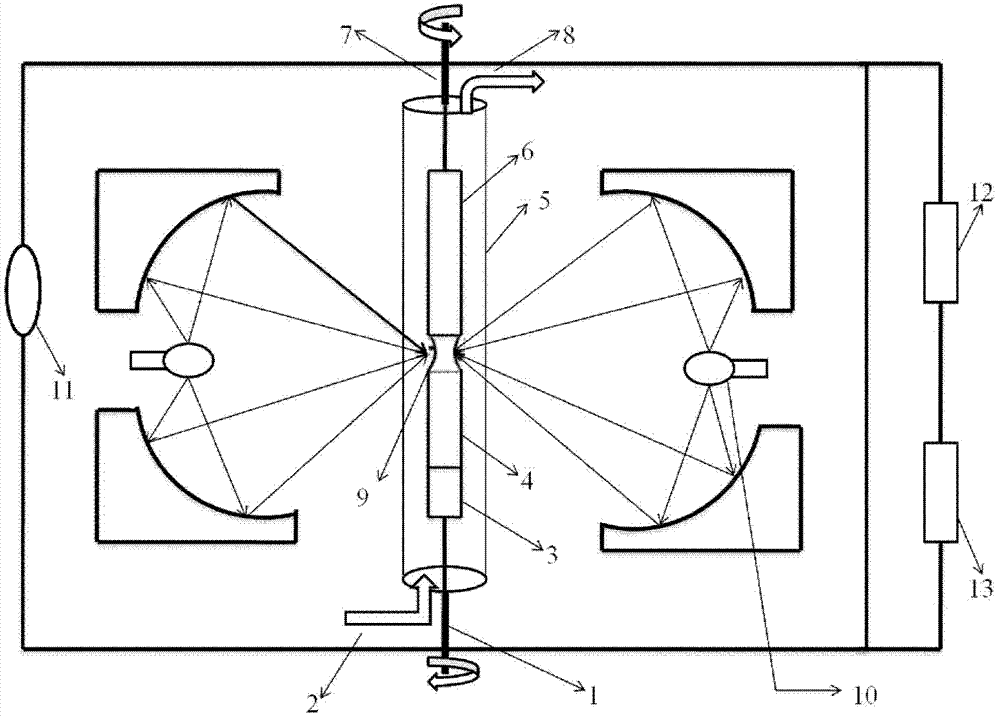

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: Five sections of Nd: YVO 4 Concentration Gradient Composite Crystal

[0052] Preparation of Nd x Y 1-x VO 4 (x=x 1 , x 2 , x 3 , x 4 , x 5 ), the chemical equation is:

[0053] wxya 2 o 3 +(1-x)Y 2 o 3 +V 2 o 5 =2Nd x Y 1-x VO 4 ;

[0054] The raw material is Nd 2 o 3 , Y 2 o 3 and V 2 o 5 , five different values of doping concentration x are taken in the ratio, which are respectively x 1 = 0.1at%, x 2 = 0.3at%, x 3 = 0.5at%, x 4 = 0.7at%, x 5 =0.9at%, the Nd 2 o 3 (4N), Y 2 o 3 (5N), and V 2 o 5 (4N) Raw material, dry properly in the air, and then strictly weigh five parts according to five different stoichiometric ratios, and mix the five parts fully, and put them into a Pt crucible in turn at 1000-1100 °C Sintering for 8 hours, the obtained polycrystalline material was ground with agate mortar and pestle respectively, and ground into fine powder, which was ground into fine powder with an average particle size of 4 μm...

Embodiment 2

[0057] Embodiment 2: Five sections of Nd:GdVO 4 Concentration Gradient Composite Crystal

[0058] Preparation of Nd x Gd 1-x VO 4 (x=x 1 , x 2 , x 3 , x 4 , x 5 ), the chemical equation is:

[0059] wxya 2 o 3 +(1-x)Gd 2 o 3 +V 2 o 5 =2Nd x Gd 1-x VO 4 ;

[0060] The raw material used is Nd 2 o 3 , Gd 2 o 3 and V 2 o 5 , take five different values of doping concentration x in the ratio, which are 0.1at%, 0.3at%, 0.5at%, 0.7at%, 0.9at%, and Nd 2 o 3 (4N), Gd 2 o 3 (5N), and V 2 o 5 (4N) Raw materials, weighed according to five different stoichiometric ratios, fully mixed, put into Pt crucibles and sintered at 1000-1100°C for 8 hours to obtain five polycrystalline materials with different ratios, ground into fine powder and averaged The particle size is 4 μm, and the polycrystalline rod prepared by the method of Example 1 is loaded into a floating zone growth furnace for crystal growth. All the other operations are the same as in Example 1.

Embodiment 3

[0061] Embodiment 3: five sections of Nd:LuVO 4 Concentration Gradient Composite Crystal

[0062] Preparation of Nd x Lu 1-x VO 4 (x=x 1 , x 2 , x 3 , x 4 , x 5 ), the chemical equation is:

[0063] wxya 2 o 3 +(1-x)Lu 2 o 3 +V 2 o 5 =2Nd x Lu 1-x VO 4 ;

[0064] The raw material used is Nd 2 o 3 , Lu 2 o 3 and V 2 o 5 , the doping concentrations are x=0.1at%, 0.3at%, 0.5at%, 0.7at%, 0.9at%, respectively. Thereafter, the preparation of raw materials, preparation of polycrystalline rods, and crystal growth, annealing, and processing are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com