Photoresist stripping solution

A stripping solution and photoresist technology, used in optics, opto-mechanical equipment, photosensitive material processing, etc., can solve the problems of ineffective removal, weak degumming ability, limited use range, etc., and achieve long service life and degumming ability. Strong, large operation window effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The advantages of the present invention are further described below through specific examples, but the protection scope of the present invention is not limited only to the following examples.

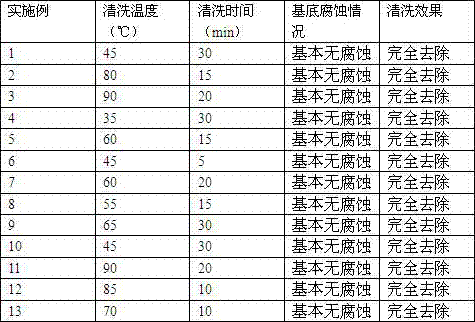

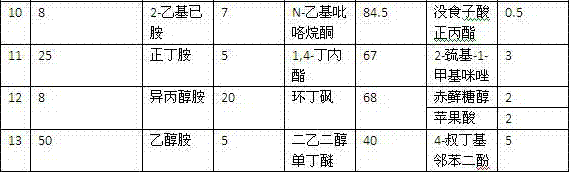

[0014] Table 1 The composition and content of cleaning solution of embodiment and comparative example

[0015]

[0016]

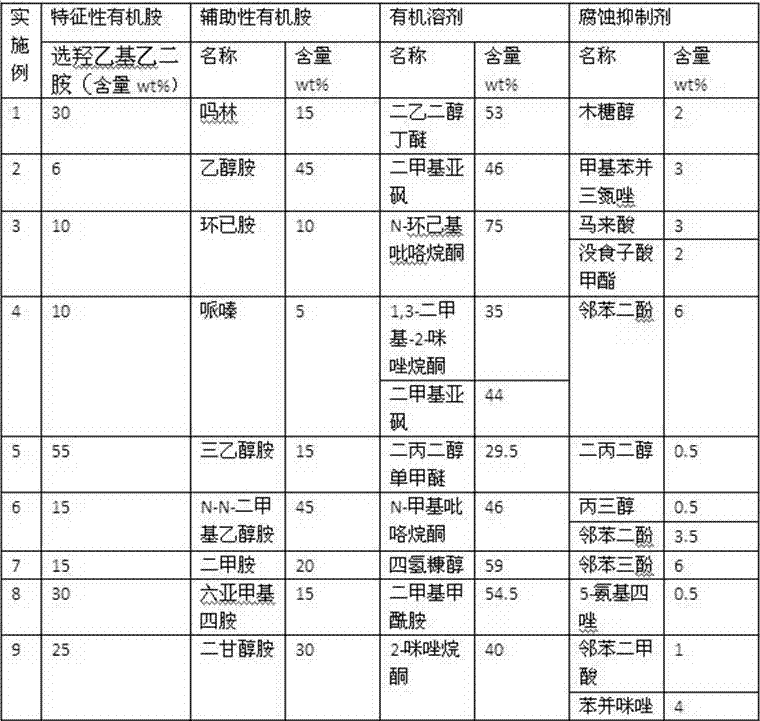

[0017] In order to further investigate the cleaning situation of this type of photoresist stripping solution, the present invention adopts the following technical means: the wafer that is about to be covered with thick film negative photoresist is cut into 3cm*3cm chips, respectively immersed in 100mL cleaning solution Soak at 30°C to 90°C for 3-30min, then rinse and dry with high-purity nitrogen. The cleaning effect of photoresist residues and the corrosion of the wafer substrate by the stripping solution are shown in Table 2

[0018]

[0019] It can be seen from Table 2 that the photoresist stripping solution of the present invention has a strong r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com