Antenna heat-dissipating integrated transceiver structure and manufacturing method

A manufacturing method and transceiver technology, applied in the direction of electric solid-state devices, semiconductor devices, electrical equipment structural parts, etc., can solve the problems of increasing thermal resistance of heat dissipation paths, large thermal resistance, and low heat dissipation efficiency, so as to reduce heat conduction paths, The effect of increasing the heat dissipation area and improving the heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

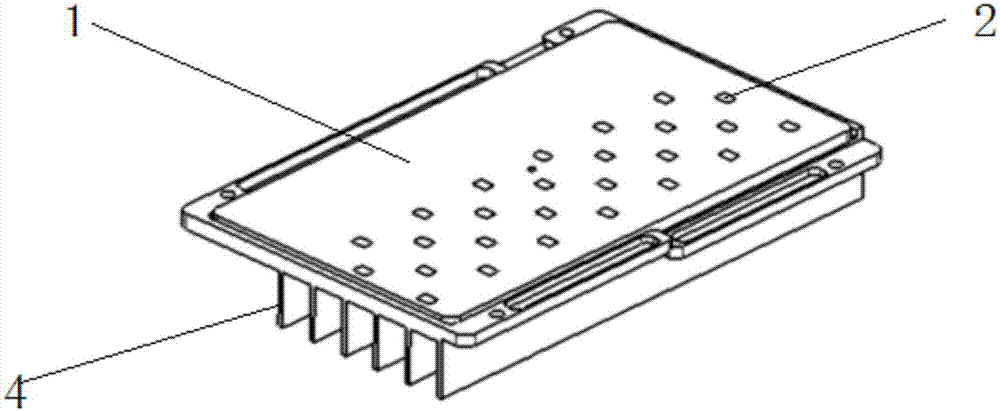

[0046] Specific embodiment 1: An antenna heat dissipation integrated transceiver array is realized, and a good heat dissipation effect and radio frequency performance are achieved in actual measurements. A specific implementation example is as follows: the size of the array is 140mm×90mm×16mm, the thickness of the substrate is 2mm, the height of the antenna is 14mm, and 26 through slots are arranged in the array. For specific implementation, see figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com