Reactor for treating VOCs (Volatile Organic Chemicals) synergistically under catalysis of plasma

A technology of synergistic catalysis and plasma, applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve the problems of low removal efficiency and high power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

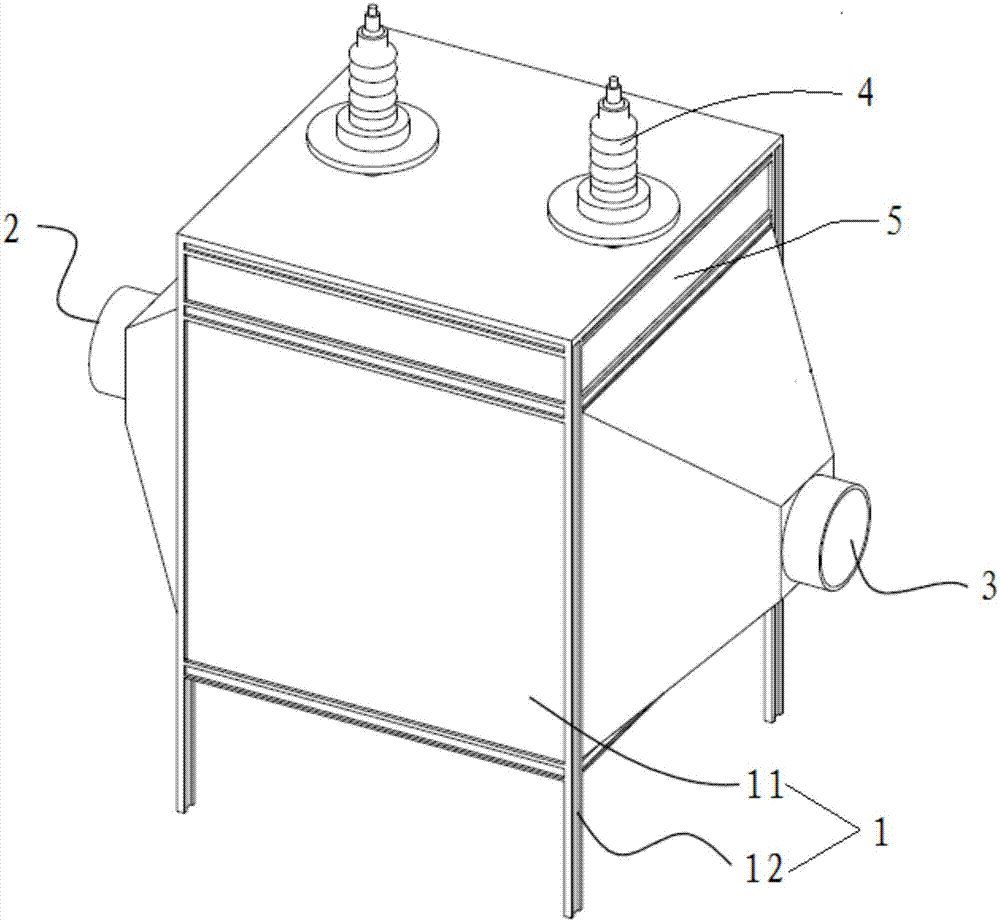

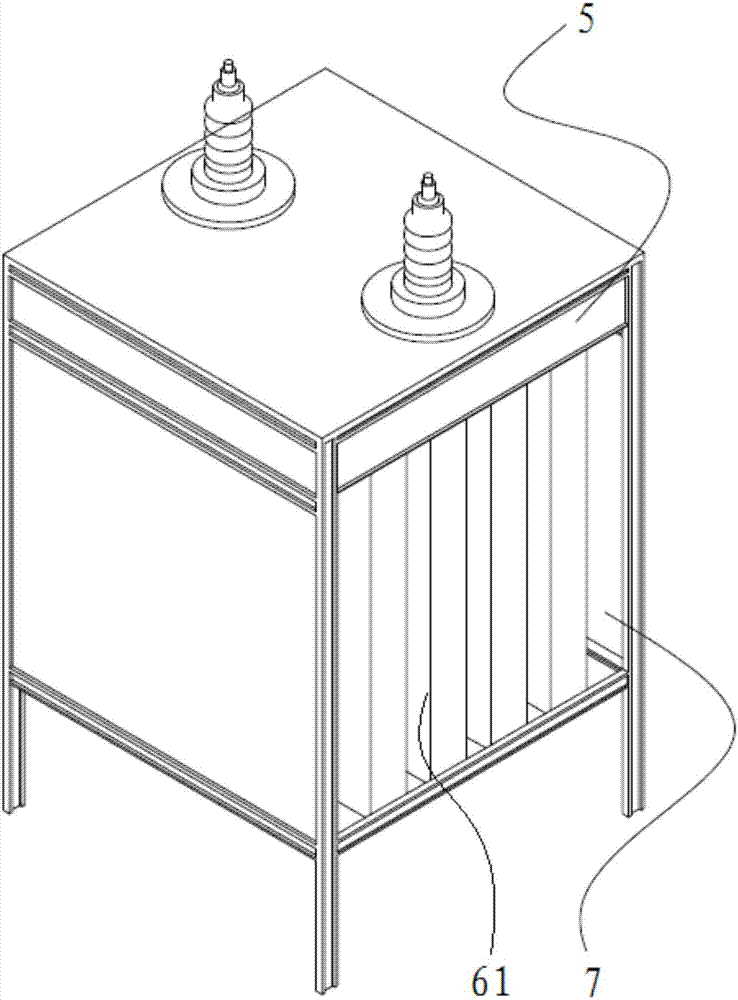

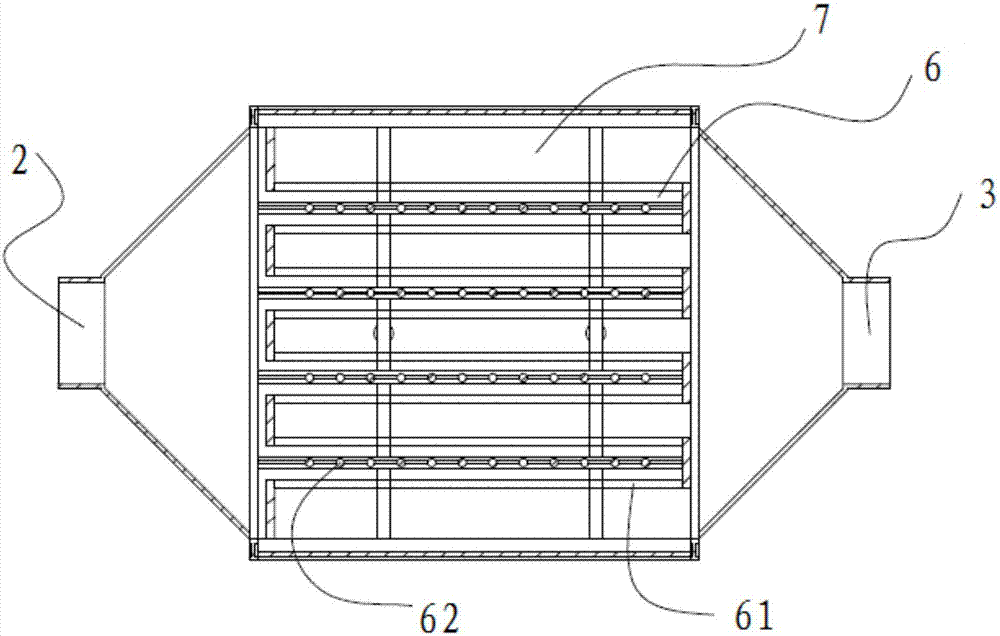

[0032] As mentioned in the background technology section, the current reactors for processing VOCs have high power consumption and low removal efficiency.

[0033] Based on the above research, the embodiment of the present invention provides a reactor for plasma synergistic catalytic treatment of VOCs. Through the insulator chamber on the upper part of the shell, the creepage distance can be increased, and pollution such as floating and sinking can be prevented from adhering to the surface of the insulator to form a path. It is broken down by the voltage at both ends of the insulator. In addition, it can also be used to support and fix the busbar and live conductors, and to ensure sufficient distance and insulation between live conductors or between conductors and the earth. It is also worth mentioning that the corona discharge can be generated by a high-voltage pulse power supply, and the low-temperature plasma is generated by using a wire-plate corona discharge. Due to the sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com