Series hybrid electric vehicle energy storage structure based on elastic energy storage and energy distribution method

A series hybrid and electric vehicle technology, applied in the direction of hybrid vehicles, motor vehicles, power plants, etc., can solve the problems of energy waste, low efficiency, cost increase, etc., and achieve the effect of simple control method and reduced use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

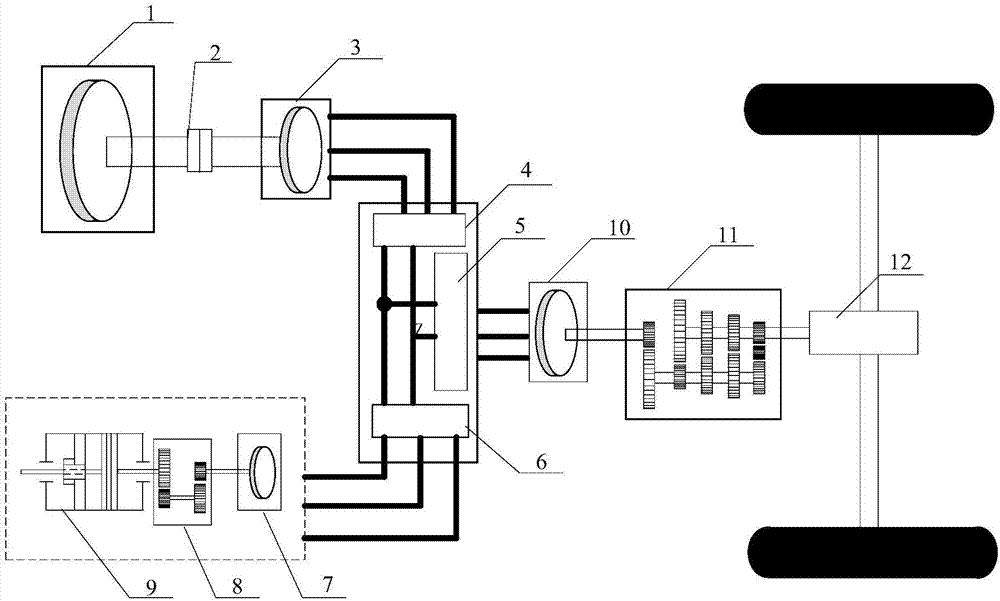

[0029] Specific implementation mode 1. Combination figure 1 This embodiment will be described. The elastic energy storage-based energy storage structure of a series hybrid electric vehicle described in this embodiment includes an engine 1 , a shaft connector 2 , a generator 3 , a rectifier circuit 4 , and a No. 1 bidirectional inverter 5 , No. 2 bidirectional inverter 6, elastic energy storage system, No. 2 motor 10, No. 2 gearbox 11 and differential 12; the elastic energy storage system includes No. 1 motor 7, No. 1 gearbox 8 and elastic energy storage tank 9;

[0030] The output shaft of the engine 1 is coaxially connected to the input shaft of the generator 3 through the shaft connector 2, the current signal output end of the generator 3 is connected to the current signal input end of the rectifier circuit 4, and the DC signal output end of the rectifier circuit 4 is connected to a The DC signal terminal of the No. 2 bidirectional inverter 5 and the DC signal terminal of t...

specific Embodiment approach 2

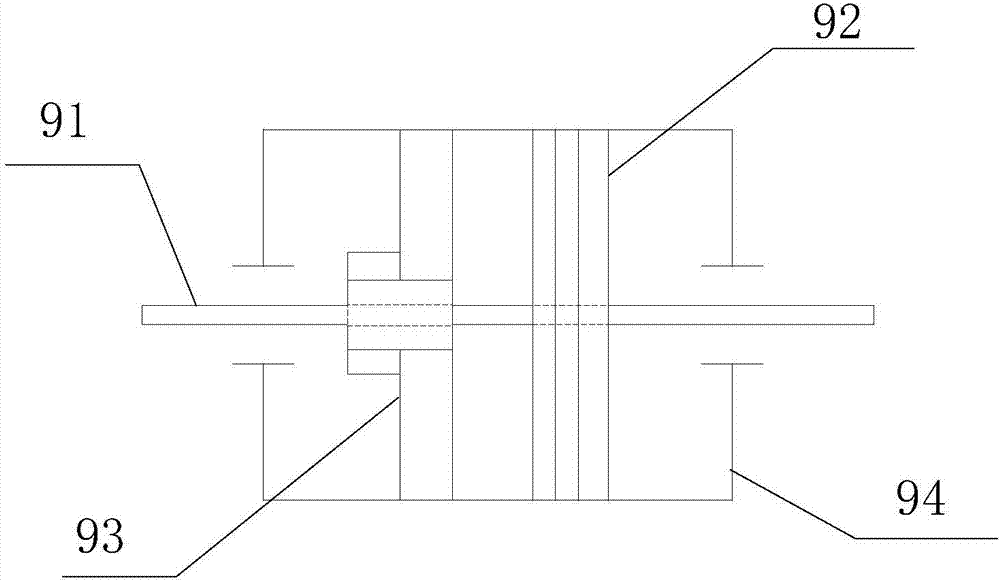

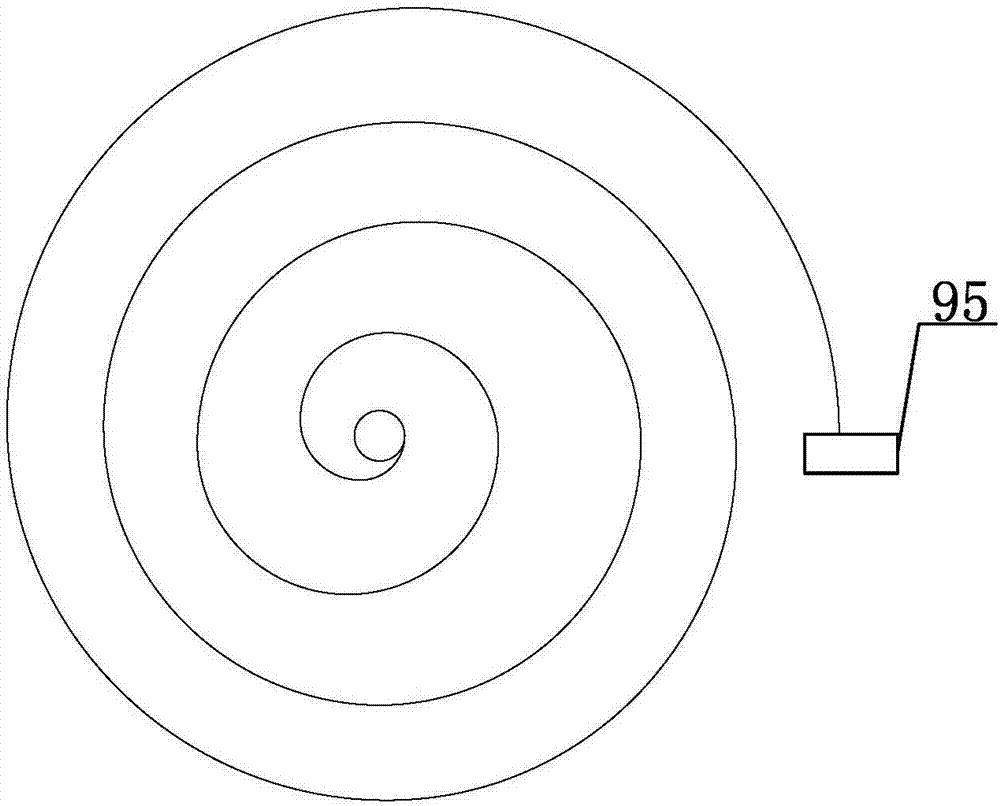

[0033] Specific embodiment 2. Combination figure 2 and image 3 This embodiment is described. This embodiment is a further description of the energy storage structure of the series hybrid vehicle based on elastic energy storage described in the specific embodiment 1. The elastic energy storage tank 9 includes a No. 1 transmission shaft 91 and an energy storage scroll spring 92. , brake 93, No. 1 box 94 and tension sensor 95;

[0034] The No. 1 drive shaft 91 is located in the middle of the No. 1 case 94 and transversely passes through the No. 1 case 94. The energy storage scroll spring 92, the brake 93 and the tension sensor 95 are all arranged in the No. 1 case 94. 92 and the brake 93 are both sleeved on the No. 1 transmission shaft 91, the tension sensor 95 is fixed on the outer end of the energy storage scroll spring 92, and the energy storage scroll spring 92 and the brake 93 are not in contact.

specific Embodiment approach 3

[0035] Specific embodiment three, combination Figure 4 This embodiment is described. This embodiment is a further description of the energy storage structure of the series hybrid vehicle based on elastic energy storage described in the specific embodiment 1. The brake 93 includes a fixed spring 931, a brake tumbler 932, a spring clip 933, Brake wheel 934, No. 2 drive shaft 935, switch tube group 937, permanent magnet 938, electromagnet 939 and No. 2 box;

[0036] The brake wheel 934 is sleeved on the No. 2 transmission shaft 935, and the upper edge of the brake wheel 934 is equally spaced with four "U"-shaped grooves, and the four "U"-shaped grooves are used for inserting the brake tumbler 932. , the end of the stopper 932 is embedded with a permanent magnet 938, the permanent magnet 938 is clamped on the vertical partition in the No. 2 box, and there is a set between the left inner wall of the No. 2 box and the partition There is a fixed spring 931, the upper and lower inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com