High-speed train energy-saving resistance reducing method and device

A technology for high-speed trains and generating devices, applied in transportation and packaging, locomotives, railway car bodies, etc., can solve problems such as reduced operational performance and deterioration of ride comfort, and achieve improved aerodynamic characteristics, improved operational safety, and reduced aerodynamic resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with specific examples, which are explanations of the present invention rather than limitations.

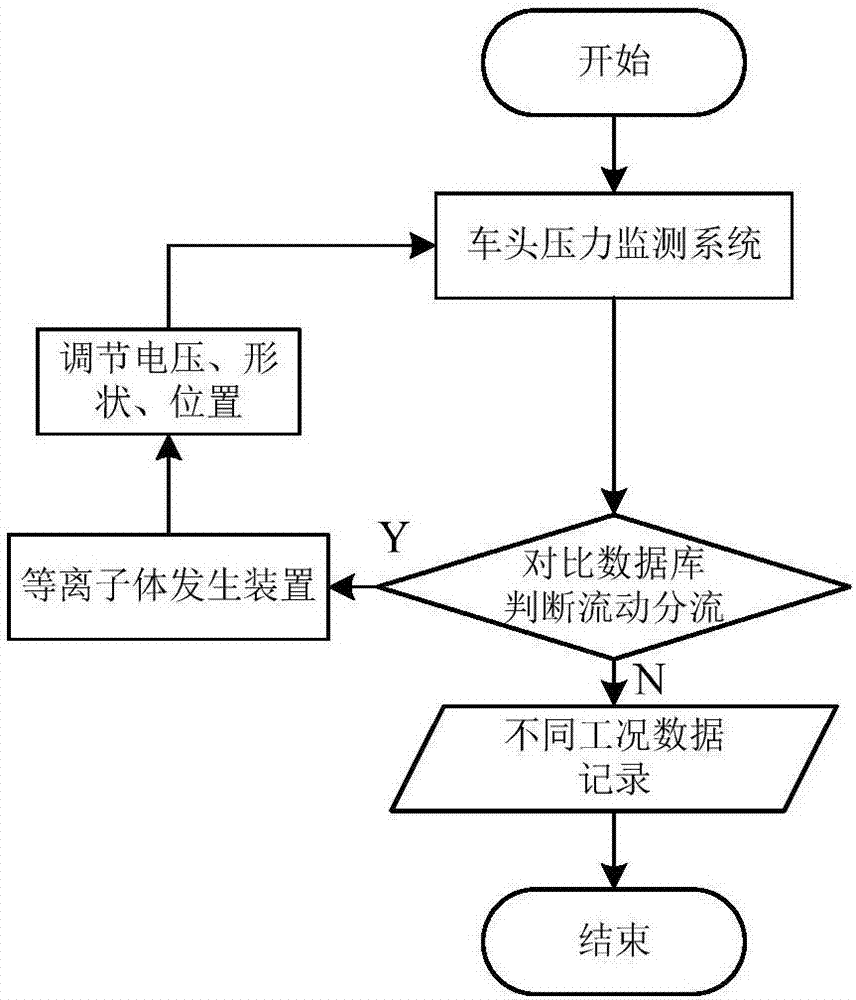

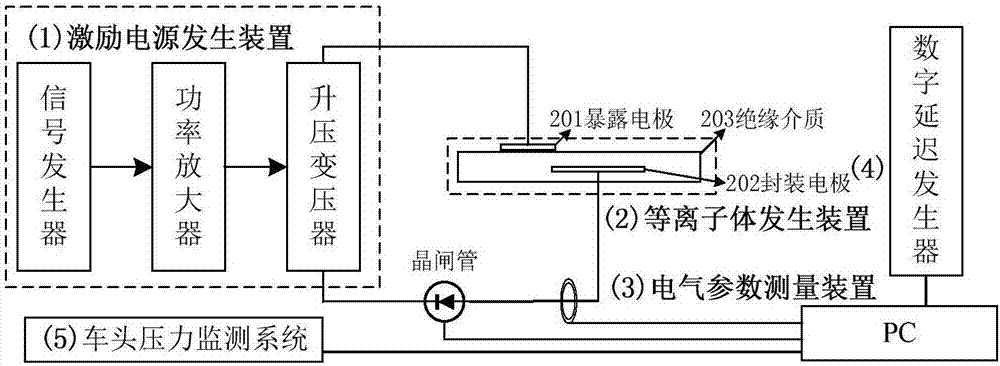

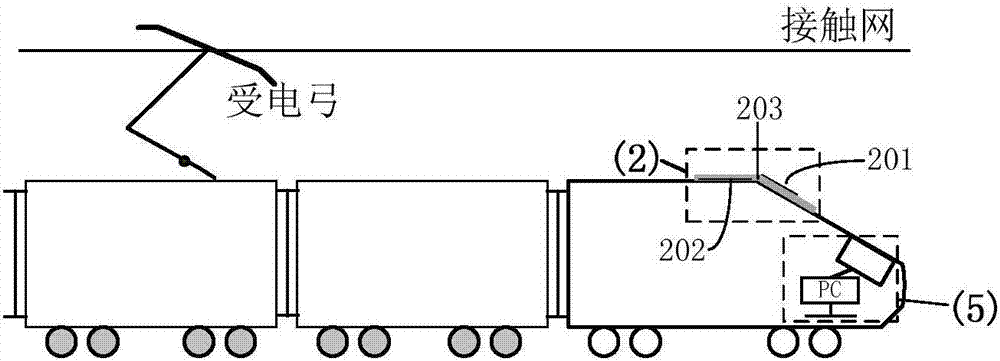

[0028] see figure 1 , a high-speed train energy-saving and drag-reducing device, comprising: an excitation power generating device, a plasma generating device, an electrical parameter measuring device, a digital delay generator, and a pressure monitoring system; wherein, the signal generator in the excitation power generating device is connected to a power amplifier , the power amplifier is connected to the step-up transformer; both ends of the step-up transformer are connected to the plasma generator; the plasma generator is connected to the electrical parameter measuring device; the pressure monitoring system is connected to the PC.

[0029] The switching thyristors of the excitation power generation device are all triggered by a digital delay generator; in addition, the digital delay generato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com