Diamine, polyamic acid or derivative thereof, liquid crystal alignment agent, liquid crystal alignment film, and liquid crystal display element

A technology of polyamic acid and derivatives, which is applied in liquid crystal materials, chemical instruments and methods, organic chemistry, etc., and can solve problems such as brightness reduction and grayscale display hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0704] [Example 1] Preparation of varnish

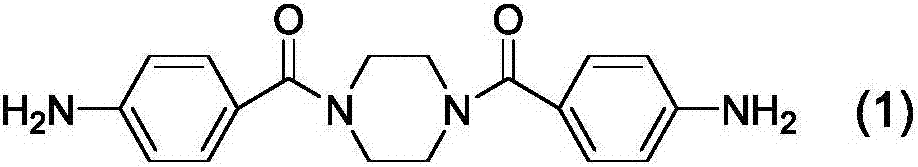

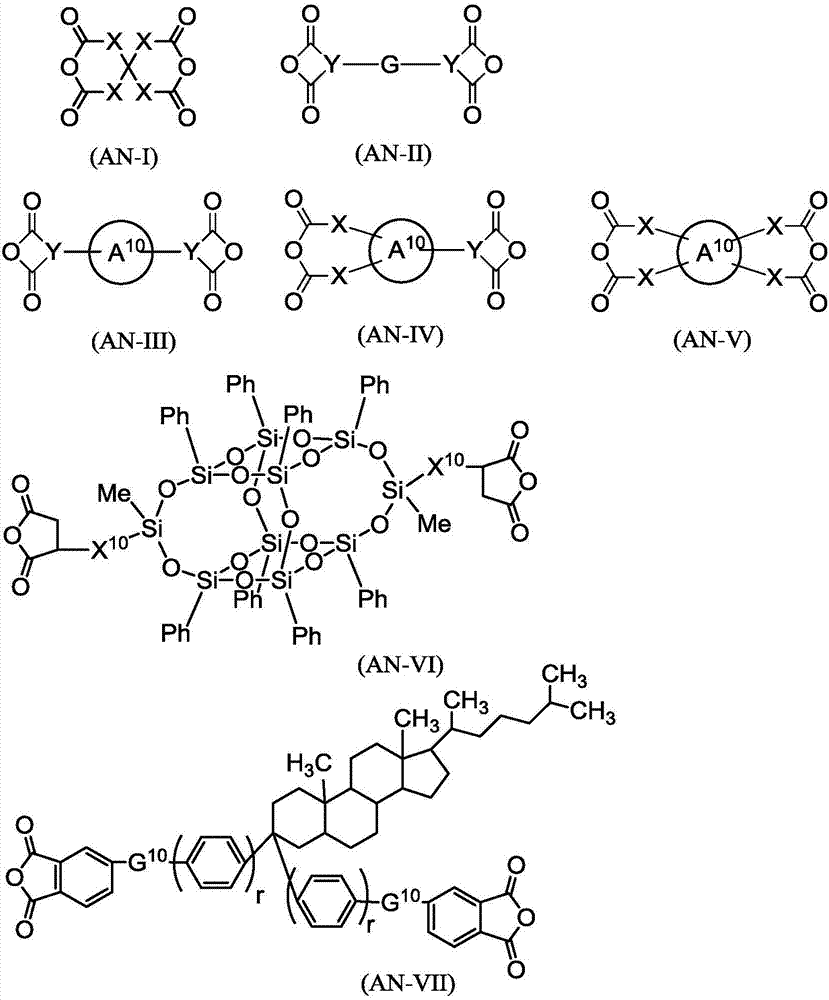

[0705] Put compound DI-5-1 (m=1) 1.2698g into a 200mL eggplant-shaped flask equipped with a thermometer, a nitrogen purge port, and a stirring bar, and formula (1) synthesized by the method described in Japanese Patent Application Laid-Open No. 50-19897 The indicated compound was 2.0774g, NMP 59.0g and GBL 15.0g were added. The solution was cooled to 5° C. or lower, 1.3969 g of the compound represented by the formula (AN-3-2) and 1.2560 g of the compound represented by the formula (PA-1) were charged thereinto, and further stirred at room temperature for 6 hours. To this, 20.0 g of butyl cellosolve (BC) was added, heated and stirred at 70° C. until the viscosity of the solution became about 35.0 mPa·s, and varnish 1 having a solid content of 6 wt % was obtained. The weight average molecular weight (Mw) of this varnish was 67000.

Embodiment 2~ Embodiment 23 and comparative example 1~5

[0707] According to the method described in Example 1, the following varnish with a solid content of 6 wt % was obtained. The composition and weight average molecular weight (Mw) of the obtained varnish are shown in Table 1-1 and Table 1-2. Example 1 is described again. The inside of [ ] represents the molar ratio of each in the tetracarboxylic acid compound group and the diamine compound group.

[0708] [Table 1-1]

[0709]

[0710] [Table 1-2]

[0711]

Embodiment 24

[0713]

[0714] Weighed 10 g of varnishes 1 in a 50 mL eggplant-shaped flask, added 10 g of N-methyl-2-pyrrolidone and 10 g of butyl cellosolve there, shaken for 2 hours, and obtained liquid crystal aligning agent 1 with a solid content of 3 wt %. This alignment agent 1 was applied to the glass substrate with ITO electrodes and the glass substrate with column spacers / ITO electrodes by spin coating (2000 rpm, 15 seconds). After coating the film, it prebaked at 80 degreeC for about 5 minutes, and then baked at 200 degreeC for 30 minutes, and formed the liquid crystal aligning film with a film thickness of about 100 nm. Using a brushing treatment device manufactured by Iinuma Gauge Manufacturing Co., Ltd., the brushing cloth (bristle length: 1.9mm: rayon) has a bristle length pressing of 0.40mm, a base moving speed of 60mm / sec, and a roller. Under the condition that the rotation speed is 1000 rpm, the obtained polyimide film is subjected to brushing treatment. After the obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ion density | aaaaa | aaaaa |

| Ion density | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com