Mononuclear dysprosium complex and preparation method and application thereof

A complex and mononuclear technology, applied in the field of magnetic materials, achieves the effects of good repeatability, simple preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 45 mg (about 0.2 mmol) ligand 2-methyl-5,7-dibromo-8-hydroxyquinoline and 46 mg (about 0.1 mmol) DyCl 3 ·6H 2 Add O to a Pyrex tube with one end closed and about 18cm in length, add 1.0mL CH 3 OH and 0.20mL CH 3 CN, the mixed solvent of composition, dropwise add 2 drops of Et 3 N (the pH value of the solution at this time is 7.1), vacuumize the Pyrex tube, and seal the other end. Place the sealed Pyrex tube at 80°C for 80 hours of heat preservation, take it out, and cool it down to room temperature naturally. Yellow strip crystals can be observed at the bottom of the Pyrex tube. The yield is about 48.9%.

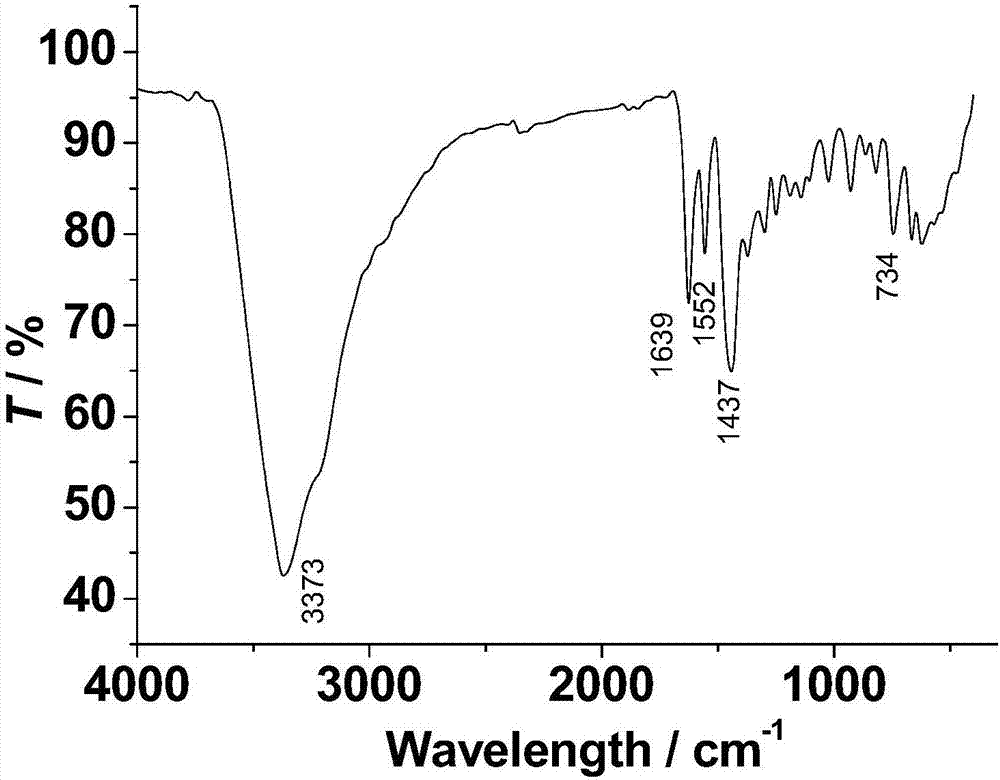

[0034] Characterize the product obtained above:

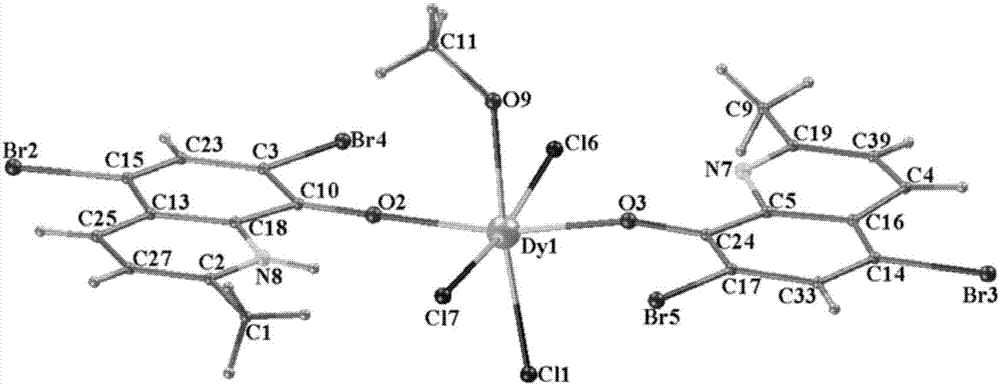

[0035] 1) Crystal structure analysis:

[0036] The yellow strip crystals with a good surface structure were measured by single crystal diffraction to determine their crystal structure. The obtained crystal structure data are shown in the aforementioned Table 1, and the bond length and bond angle data are shown in...

Embodiment 2

[0050] Repeat Example 1, except that the volume ratio of methanol and acetonitrile in the mixed solvent is changed to 4:1, and the total amount of the mixed solvent added remains unchanged.

[0051] After the Pyrex tube was taken out and naturally cooled to room temperature, yellow strip crystals were precipitated at the bottom of the Pyrex tube. Yield 49%.

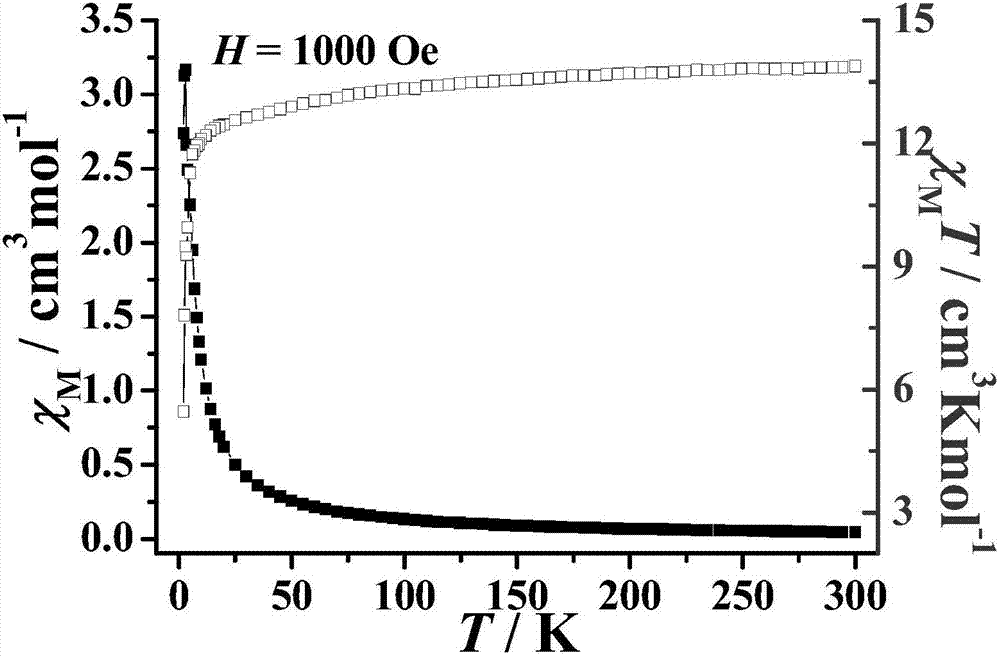

[0052] Structural characterization of the resulting product was determined to be the target complex [Dy(HL) 2 (CH 3 OH)Cl 3 ]. Characterization of the magnetic properties of the obtained product shows that the obtained product exhibits field-induced single-molecule magnet behavior at low temperature.

Embodiment 3

[0054] Repeat Example 1, except that the volume ratio of methanol and acetonitrile in the mixed solvent is changed to 3:1, and the total amount of the mixed solvent added remains unchanged.

[0055] After the Pyrex tube was taken out and naturally cooled to room temperature, yellow strip crystals were precipitated at the bottom of the Pyrex tube. Yield 47%.

[0056] Structural characterization of the resulting product was determined to be the target complex [Dy(HL) 2 (CH 3 OH)Cl 3 ]. Characterization of the magnetic properties of the obtained product shows that the obtained product exhibits field-induced single-molecule magnet behavior at low temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com