Weft yarn detection device and use method thereof

A detection device and weft yarn technology, which is applied in textiles, textiles, papermaking, looms, etc., can solve the problems of uncontrollable cloth quality and weft detection of air-jet looms, etc., and achieve the effect of easy and reliable detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

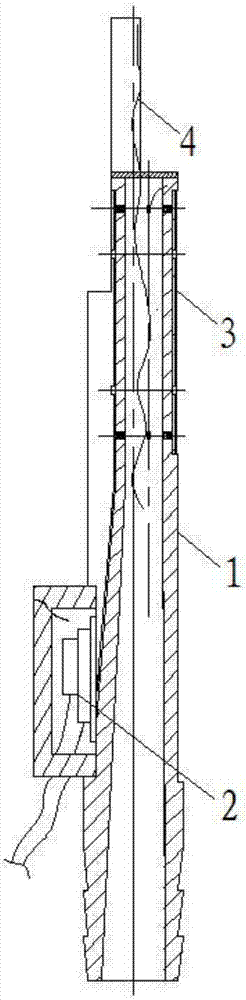

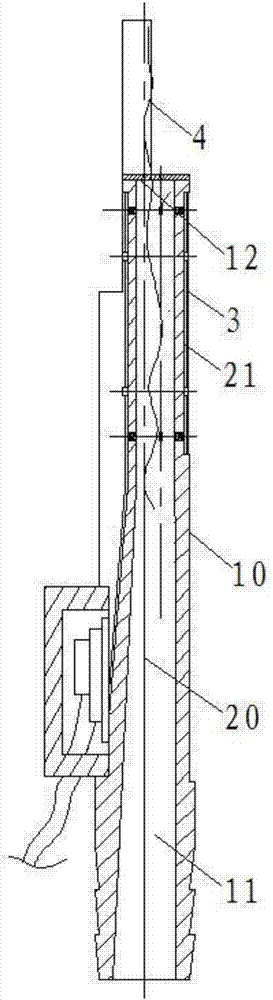

[0041] Such as Figure 1 to Figure 8 as well as Figure 10 As shown, the described weft yarn detecting device includes a hemming nozzle 1, a circuit board assembly 2 connected with the hemming nozzle 1 and a weft detecting device 3 arranged on the hemming nozzle 1, Described weft detecting device 3 comprises a long latitude detection photoelectric component 30 and a short latitude detection photoelectric component 31, and described long latitude detection photoelectric component 30 comprises a photoelectric emission tube 32 and a photoelectric receiving tube 33, and the short weft detection photoelectric component Component 31 comprises a second photoelectric emission tube 34 and a second photoelectric reception tube 35, and described weft detecting device 3 is provided with a long latitude detection photoelectric component 30 and a short latitude detection photoelectric component 31 at least so that the photoelectric emission tube 32 At least one photoelectric receiving tube...

Embodiment 2

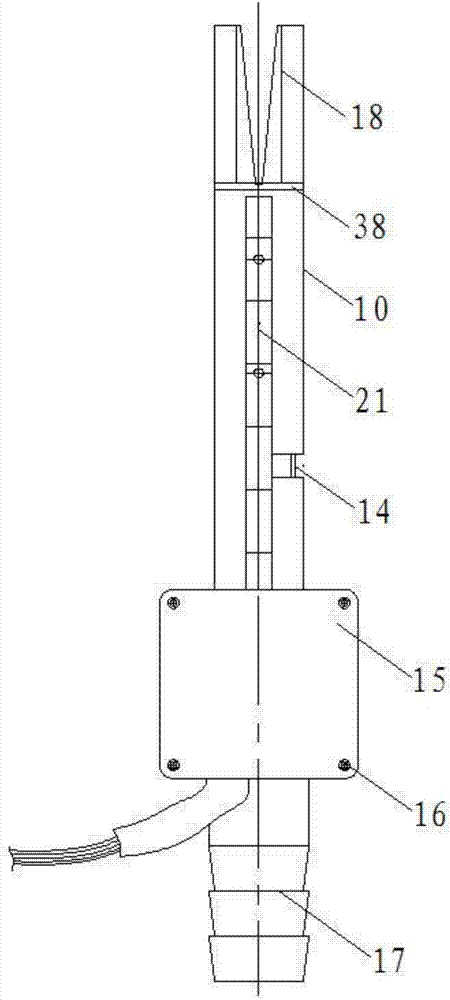

[0053] Such as Figure 9 as well as Figure 11 As shown, the nozzle main body 10 is provided with the long weft detection photoelectric component 30 and the short weft detection photoelectric component 31, and the positions from the trapezoidal yarn-entry end 12 of the nozzle main body 10 to the second connecting hole 28 are equal in height, etc. A wide trapezoidal hole, from the position of the trapezoidal hole to the nozzle channel 11 and away from the trapezoidal yarn-entry end 12 is an inner hole that gradually expands, and the inner hole is trumpet-shaped.

[0054] Wherein, the nozzle main body 10 is provided with the long latitude detection photoelectric assembly 30 and the short weft detection photoelectric assembly 31, the nozzle main body 10 is connected with a capillary 26, and the nozzle main body 10 and the capillary A suction pipe 24 is arranged between 26, and the suction pipe 24 is connected through a blocking block 25 arranged on the thin tube 26, and a first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com