Automatic height adjusting device based on advanced hypocenter detection of shearer and applied to shearer as well as method

A technology of advanced detection and shearer, applied in driving devices, cutting machinery, earth-moving drilling, etc., can solve the problems of inability to fully meet actual production, limited application scope and high degree of danger, and achieve the breakthrough of coal and rock identification technology. The effect of relying on, improving detection accuracy, and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

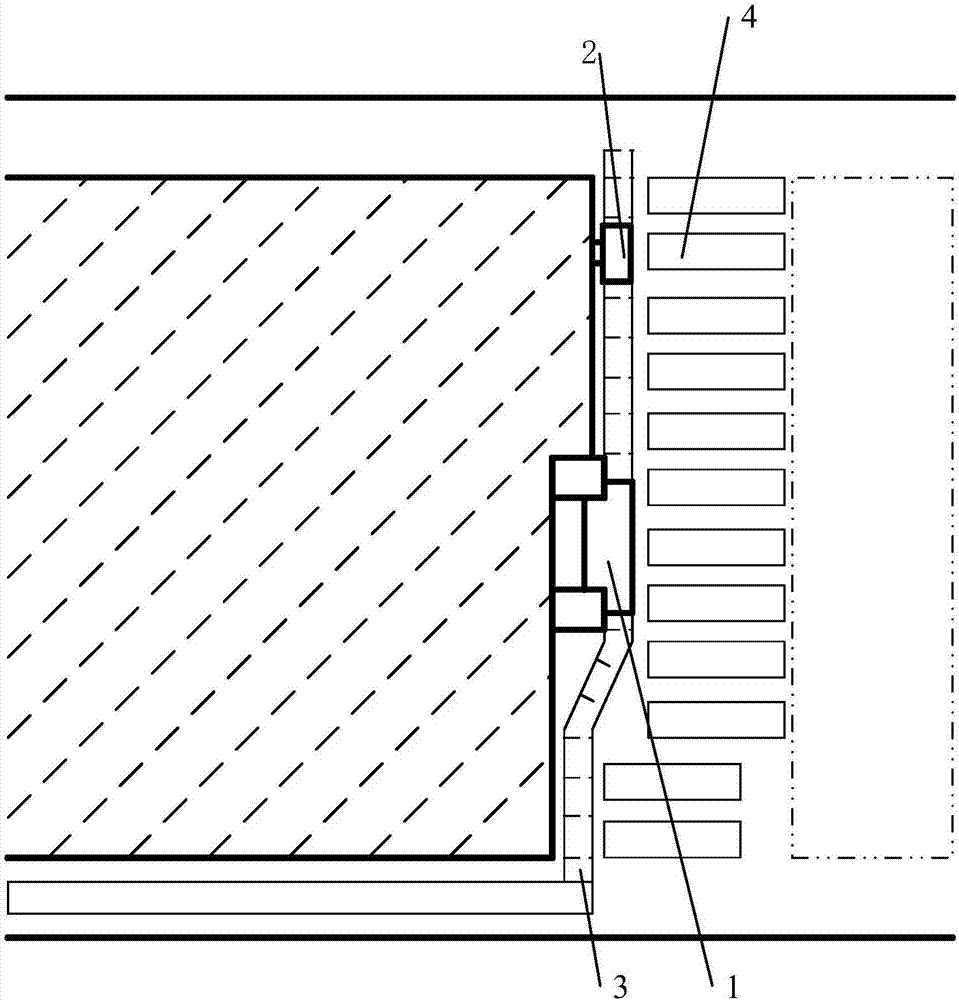

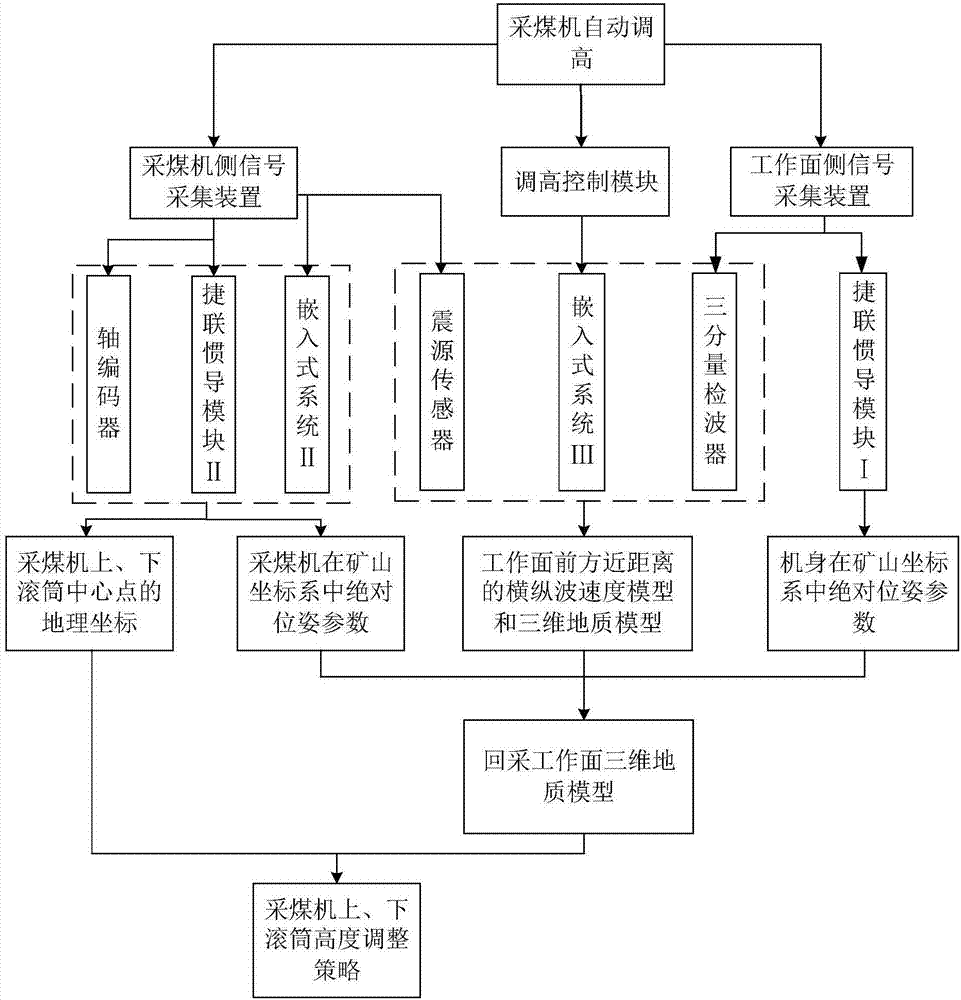

[0027] Such as figure 1 Shown is the schematic diagram of the mining face of the automatic height adjustment device for the shearer of the present invention. The automatic height adjustment device for the shearer based on the advance detection of the seismic source of the shearer of the present invention, when the mining face is recovered, mainly consists of the shearer 1 The shearer 1 in the three-machine supporting mining equipment consisting of a scraper machine 3 and a hydraulic support 4 performs automatic height adjustment; it is characterized in that it includes a shearer side signal acquisition device, a working face side signal acquisition device 2 and a height adjustment control module.

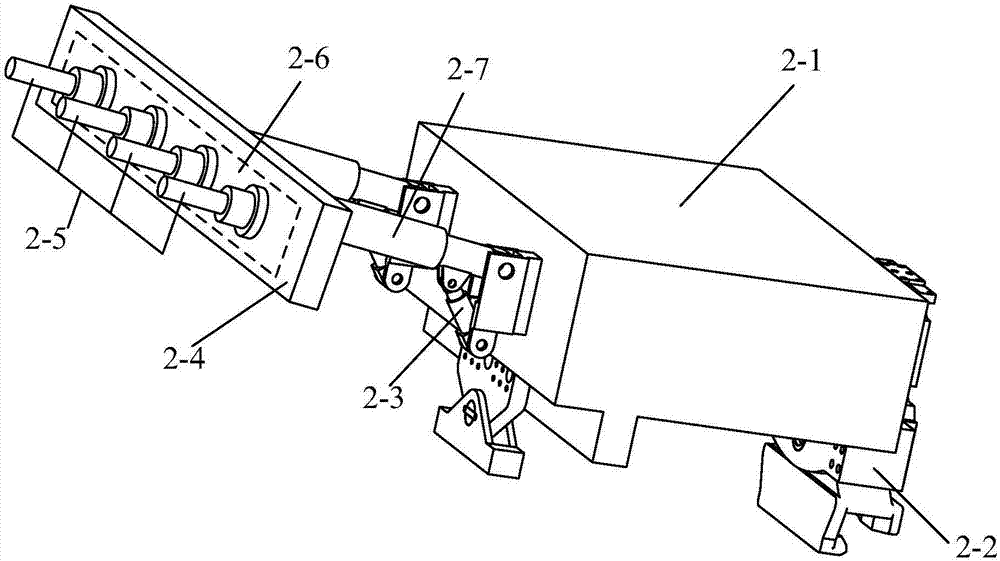

[0028] The signal acquisition device on the shearer side includes a strapdown inertial navigation module II, a shaft encoder, a source sensor and an embedded system II; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com