Lithium battery pole piece high speed die cutting machine

A die-cutting machine and lithium battery technology, applied in battery electrodes, primary battery electrodes, electrode forming, etc., can solve problems affecting stamping accuracy and equipment stability, improve stamping accuracy, meet high-speed operation requirements, maintain The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

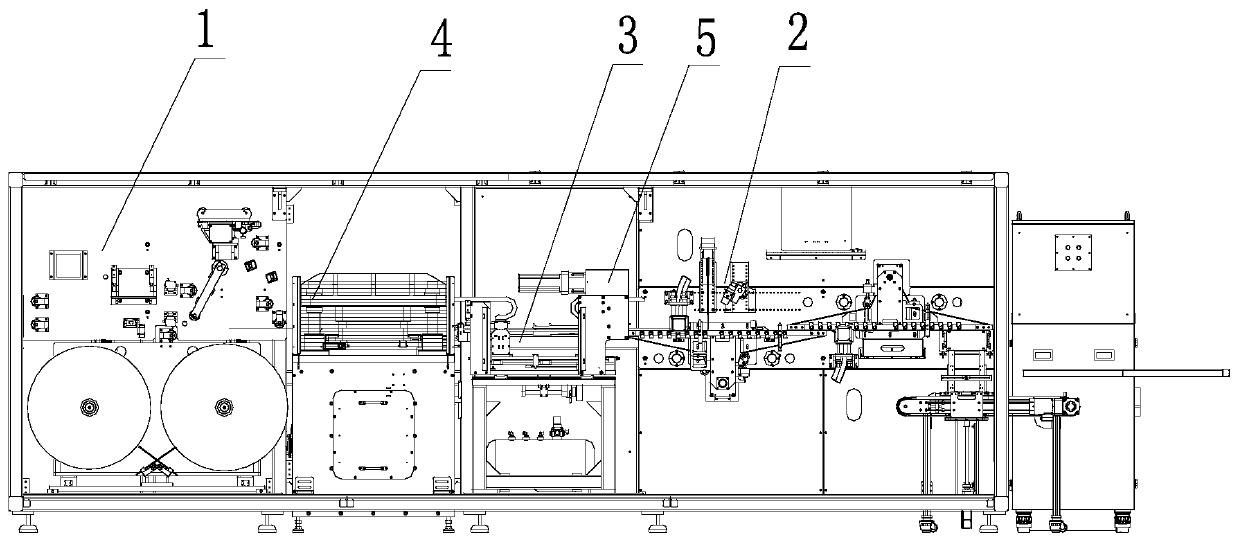

[0026] Such as figure 1 As shown, the present invention includes a reel unwinding mechanism 1, several guide rollers 12, a deviation correction mechanism, a servo press 4 for forming, a strip traction mechanism 3, a cutter assembly 5 for cutting the strip, and a blank Delivery system 2.

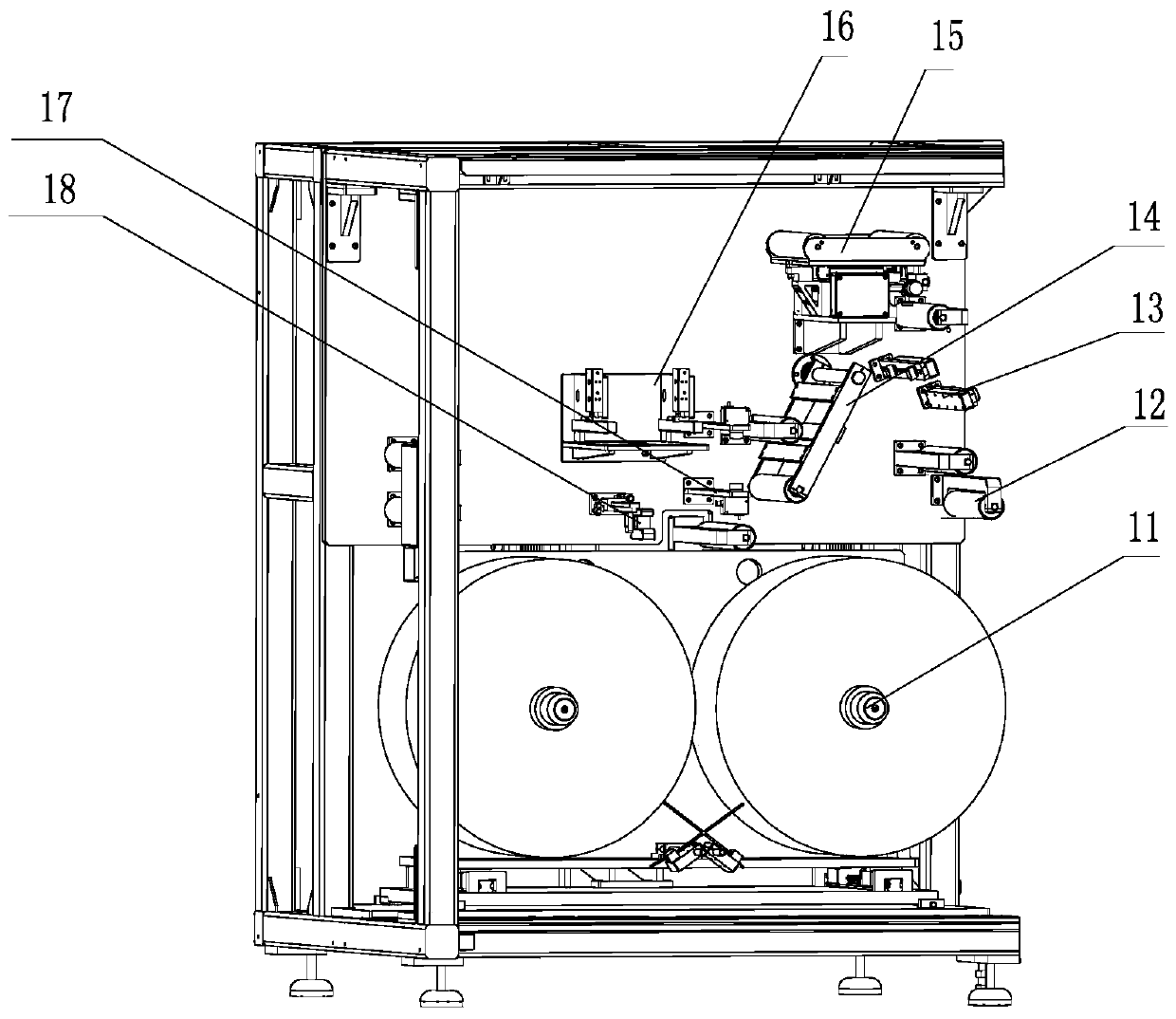

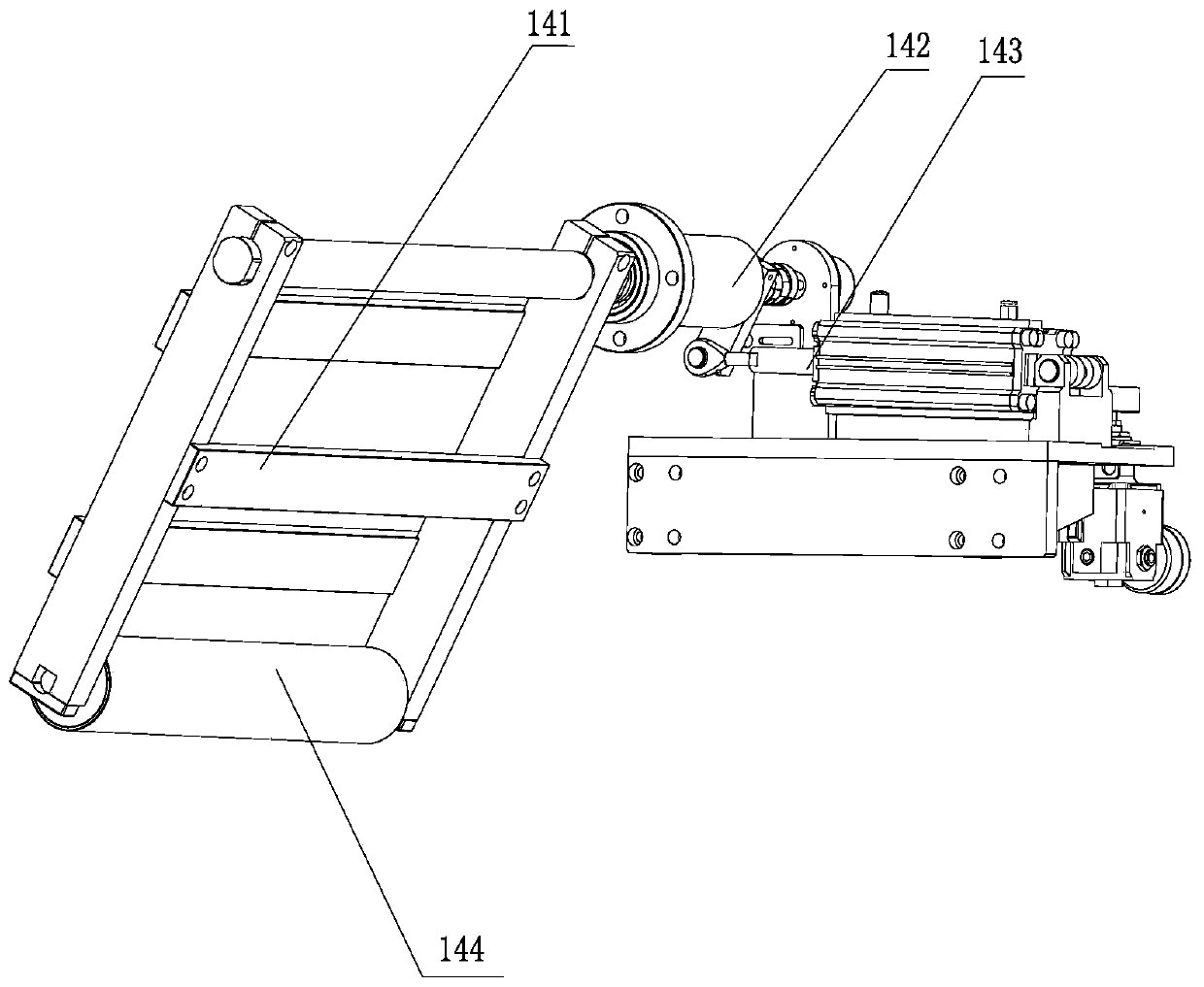

[0027] Among them, the tray unwinding mechanism 1 such as figure 2 and image 3 As shown, it mainly includes a double-material unwinding reel 11 and a constant tension mechanism 14. The constant tension mechanism includes a swing arm assembly 141, a shaft center assembly 142, an angle sensor, and a cylinder 143 that drives the swing arm assembly to swing; one end of the swing arm assembly 141 is provided The tension adjusting roller 144 is used to adjust the tension of the strip, and the other end is arranged on the shaft assembly 143 to sw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap