Aircraft sheet-shaped fuselage body

An aircraft and fuselage technology, applied in the field of aircraft sheet fuselage, can solve the problems of lack of unpowered forced landing measures, poor maneuverability, poor coordination of flight mechanism, etc., achieve a good level of flight aerodynamic characteristics, improve roll stability, improve The effect of flight stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

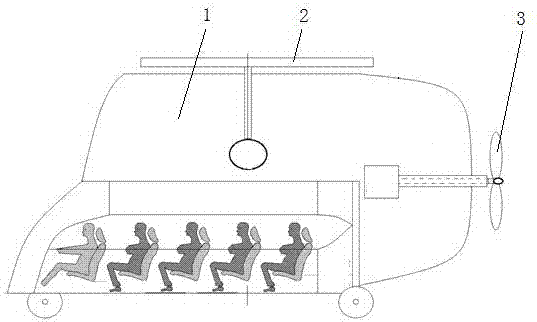

[0024] Embodiment 1: see Figure 1-2 , the sheet fuselage of the aircraft of the present invention is used for vertical take-off and landing manned aircraft, the sheet fuselage 1 is an integral structure, its overall height and length are far greater than the width, the bottom is the cabin 1-2 of 0.5m, the top closes narrow. The entire flaky body 1 has an aspect ratio of 3 and an aspect ratio of 5, presenting a "flaky" feature. The rotor 3 is arranged above the fuselage, and the driving equipment and passengers are arranged at the lower part of the fuselage along the length direction. The center of gravity of the fuselage is obviously lower than that of a conventional aircraft fuselage. The special geometric shape of the sheet-shaped fuselage ensures that the fuselage is not blocked by the airflow in the horizontal direction and the vertical direction, and has good aerodynamic characteristics for vertical take-off and landing and horizontal flight. The section of the windwar...

Embodiment 2

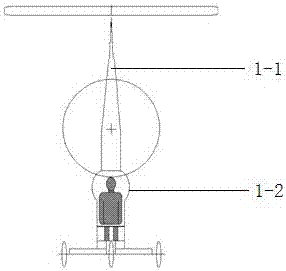

[0025] Example 2: see image 3 , the aircraft sheet fuselage of the present invention is used for vertical take-off and landing manned aircraft, the sheet fuselage 1 is a combined structure of a cabin 1-2 and a deflector 1-1, and the deflector 1-1 is a continuous surface structure and is located at The front part of the cabin 1-2 forms a tail-type sheet-shaped fuselage. The width of the cabin 1-2 is 1m. The height and length of the entire fuselage are far greater than the width. Presents a "flaky" character. The rotor 3 is arranged at the rear of the fuselage, and the driving equipment and passengers are arranged at the lower part of the fuselage along the length direction of the cabin. The center of gravity of the fuselage is obviously lower than that of a conventional aircraft fuselage. The special geometric shape of the sheet-shaped fuselage ensures that the fuselage is not blocked by the airflow in the horizontal direction and the vertical direction, and has good aerodyna...

Embodiment 3

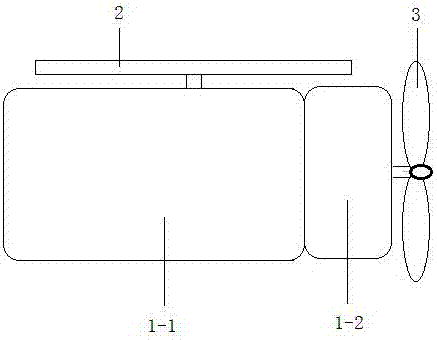

[0026] Embodiment 3: see Figure 4 , the aircraft sheet fuselage of the present invention is used for vertical take-off and landing manned aircraft, the sheet fuselage 1 is a combined structure of a cabin 1-2 and a deflector 1-1, and the deflector 1-1 is a continuous surface structure and is located at The rear part of the cabin 1-2 forms a front cabin type sheet fuselage. The width of the cabin 1-2 is 1m. The height and length of the entire fuselage are far greater than the width. Presents a "flaky" character. The rotor 3 is arranged at the rear of the fuselage, and the driving equipment and passengers are arranged at the lower part of the fuselage along the length direction of the cabin. The center of gravity of the fuselage is obviously lower than that of a conventional aircraft fuselage. The special geometric shape of the sheet-shaped fuselage ensures that the fuselage is not blocked by the airflow in the horizontal direction and the vertical direction, and has good aerod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com