A construction method for strengthening existing subway tunnel structures with high-performance composite mortar

A technology of tunnel structure and existing subway, applied in the direction of tunnel, tunnel lining, earthwork drilling, etc., can solve the problems of lack of reinforcement strength, easy falling off of steel pipe pieces, poor pertinence, etc., achieving simple and convenient construction and transportation, high practical value, Use good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

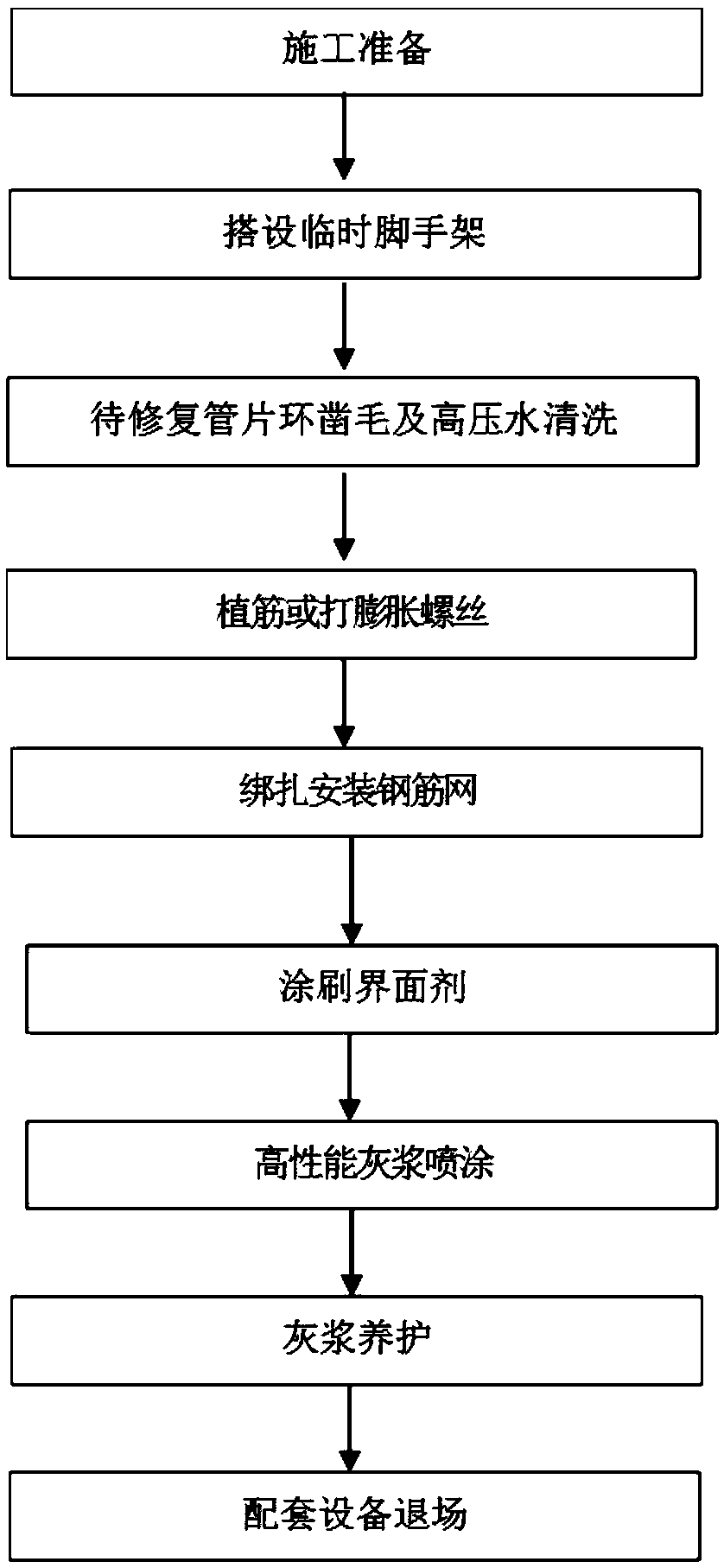

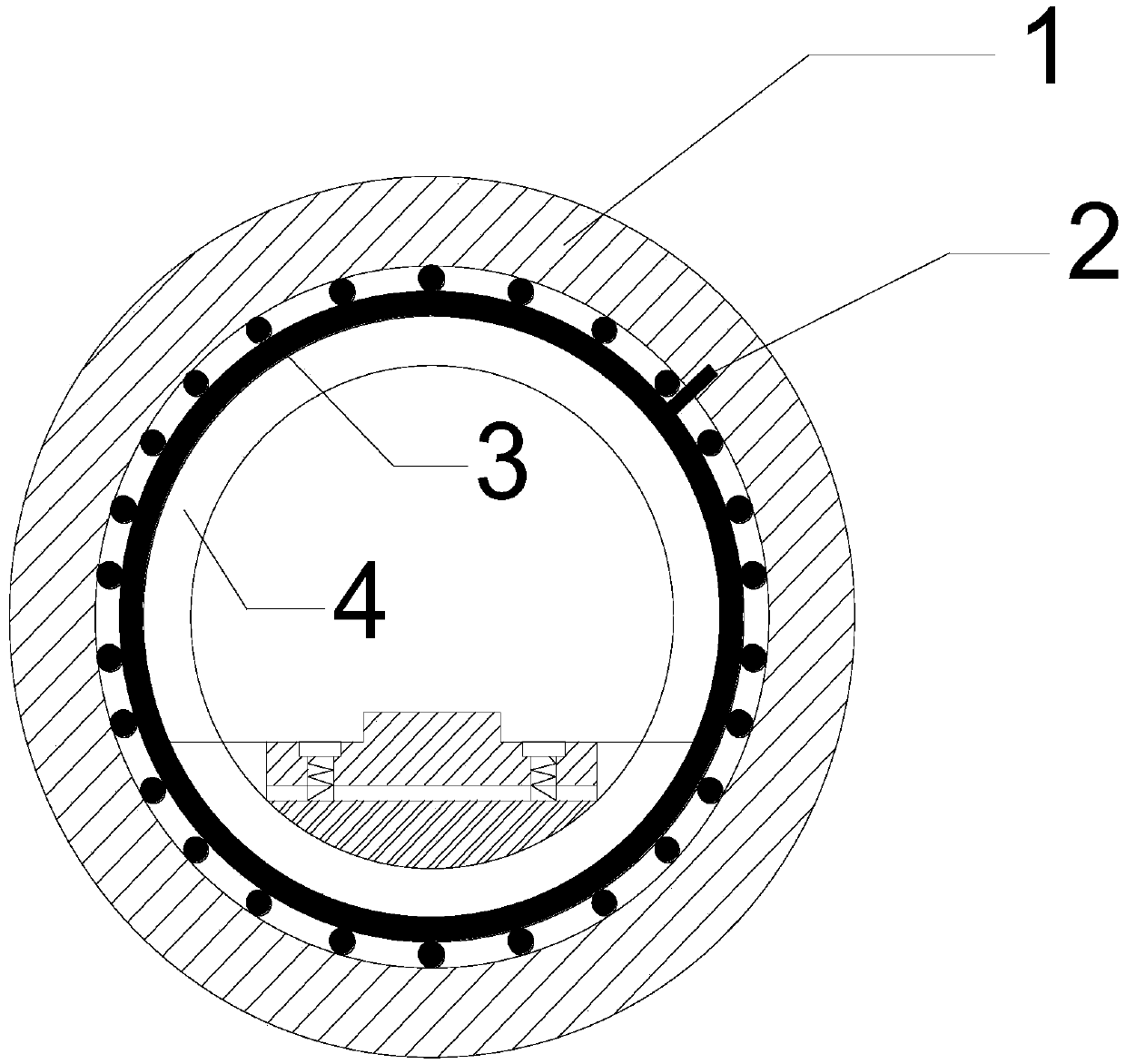

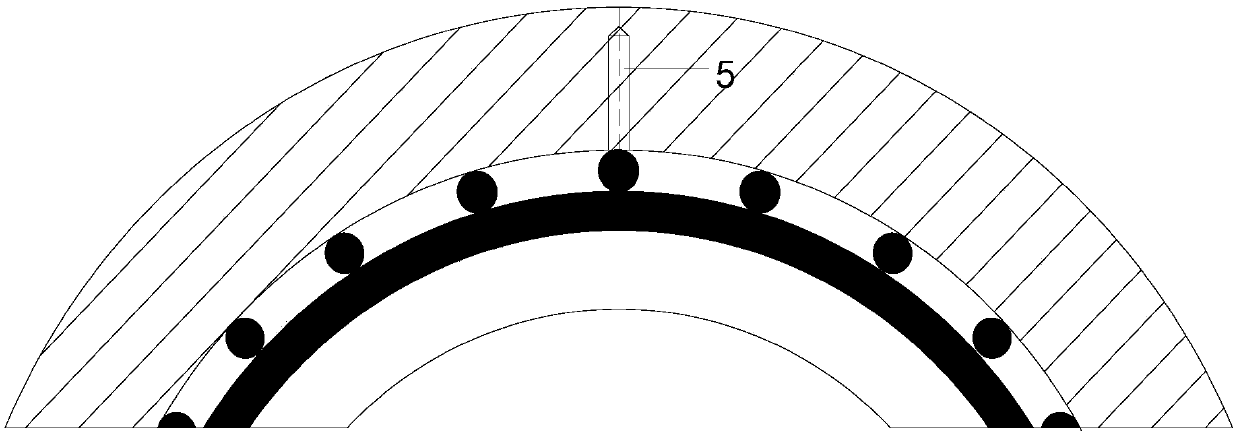

[0031] refer to Figure 1 to Figure 5 , a construction method for strengthening existing subway tunnel structures with high-performance composite mortar, and the steel mesh is bound according to Φ12@100×200mmHRB400 grade rebar 3 specifications. The steel bar 6 mesh is fixed to the inner wall of the shield segment 1 through expansion screws or planting bars 2 and closely adhered to the bottom layer, and expansion screws or planting bars 2 are driven into the inner wall of the shield segment 1 at a certain interval. Brushing the binder 7 on the outer layer of the steel bar is beneficial to the bonding of the old and new concrete structures. The spraying process is completed in two steps: the first pass of spraying makes the mortar completely cover the reinforcement mesh, and artificial leveling is carried out; after the wrapping layer of the reinforcement 6 is solidifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com