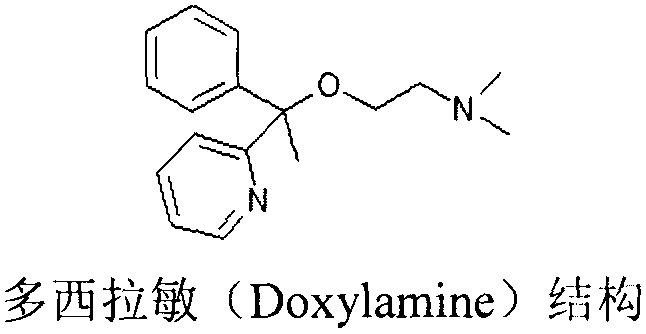

Doxylamine succinate preparation method

A technology of doxylamine succinate and succinic acid is applied in the field of preparation of antihistamine drug doxylamine succinate, and the effect of simple operation is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Doxylamine succinate crude product 2.0g, acetone 8g, triethylamine 0.11g, heated under stirring to dissolve completely, then placed at 10°C-20°C for crystallization, filtered, and vacuum dried at 50°C to obtain white crystalline doxylamine succinate Sirilamine 1.46g, melting point 103.6-104.1°C, content 99.5%.

Embodiment 2

[0025] Doxylamine succinate crude product 2.0g, absolute ethanol 5g, diisopropylamine 0.3g, fully dissolved by heating under stirring, then placed at 10°C-20°C for crystallization, filtered, and vacuum dried at 50°C to obtain white crystalline amber Doxylamine acid 1.25g, melting point 103.2-104.3°C, content 99.3%.

Embodiment 3

[0027] 5.0g of crude doxylamine succinate, 20g of n-butanol, 0.8g of N,N-dimethyl-2-(diphenylmethoxy)ethylamine, heated under stirring to completely dissolve, and then placed at 10°C- Crystallize at 20°C, filter, and vacuum-dry at 50°C to obtain 3.75 g of white crystalline doxylamine succinate with a melting point of 105.2-106.0°C and a content of 99.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com