An Electromagnetic-Static Double Suspension Thrust Bearing

A technology of thrust bearings and static pressure bearings, applied to bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of low load capacity, small torque, wide temperature range, etc., increase load capacity and stiffness, relieve design restrictions, The effect of improving adjustment ability and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

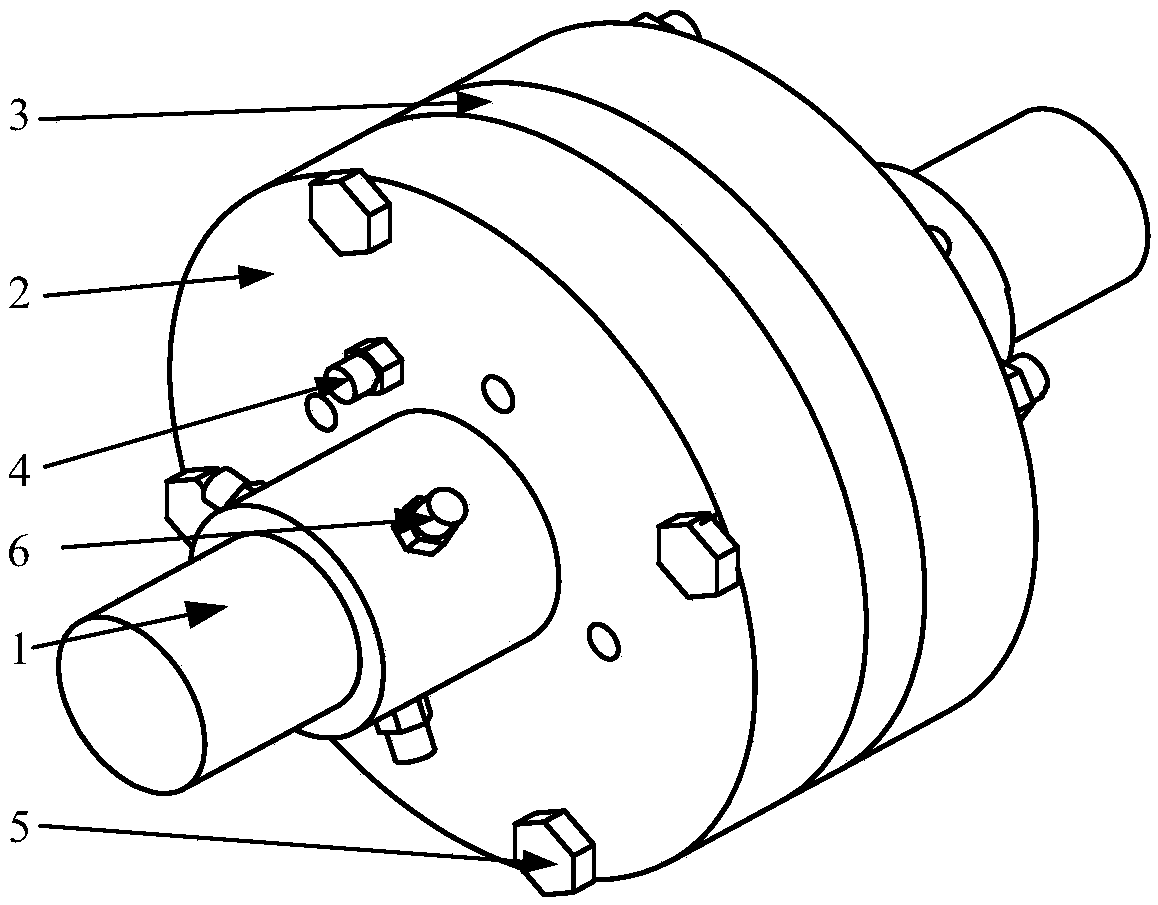

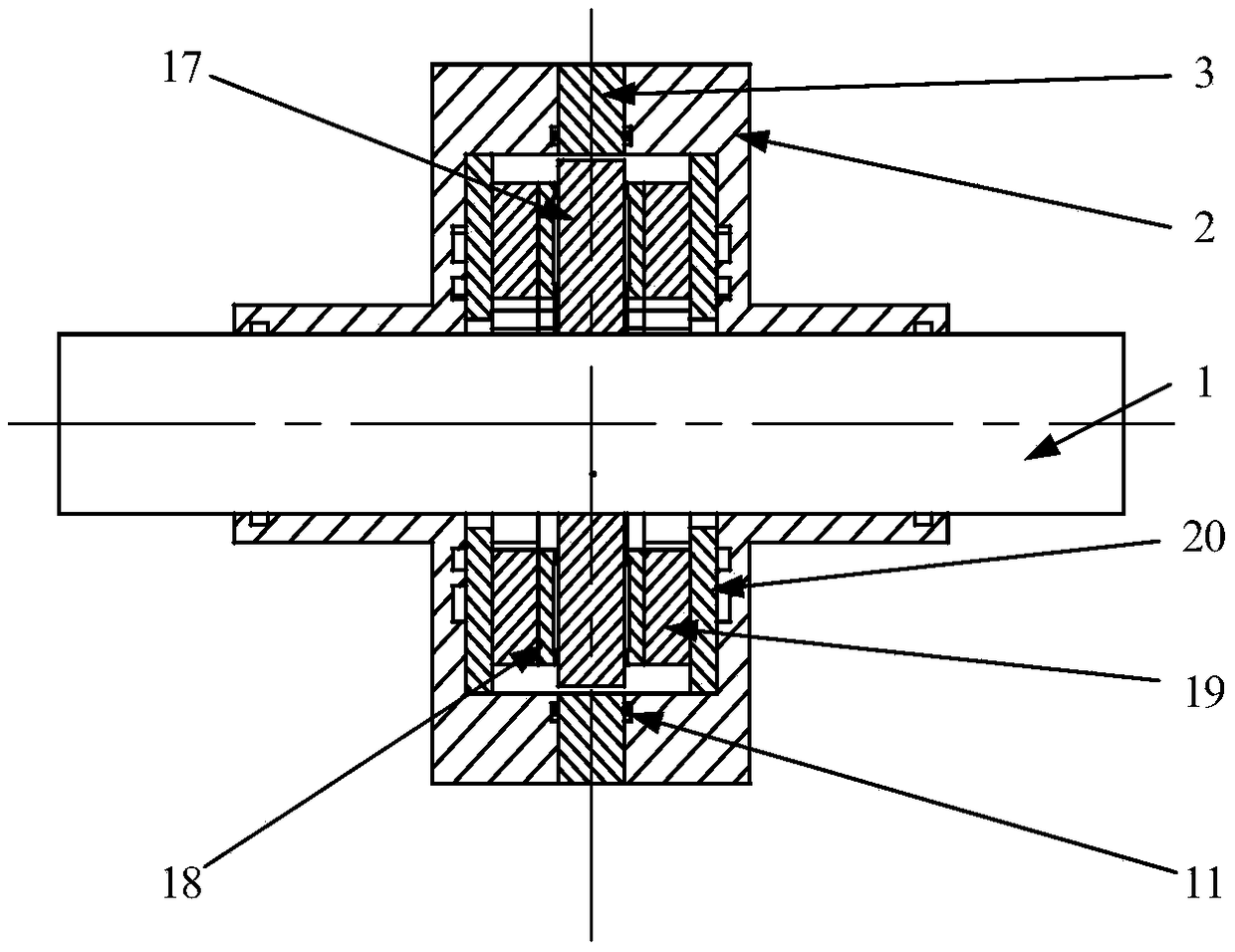

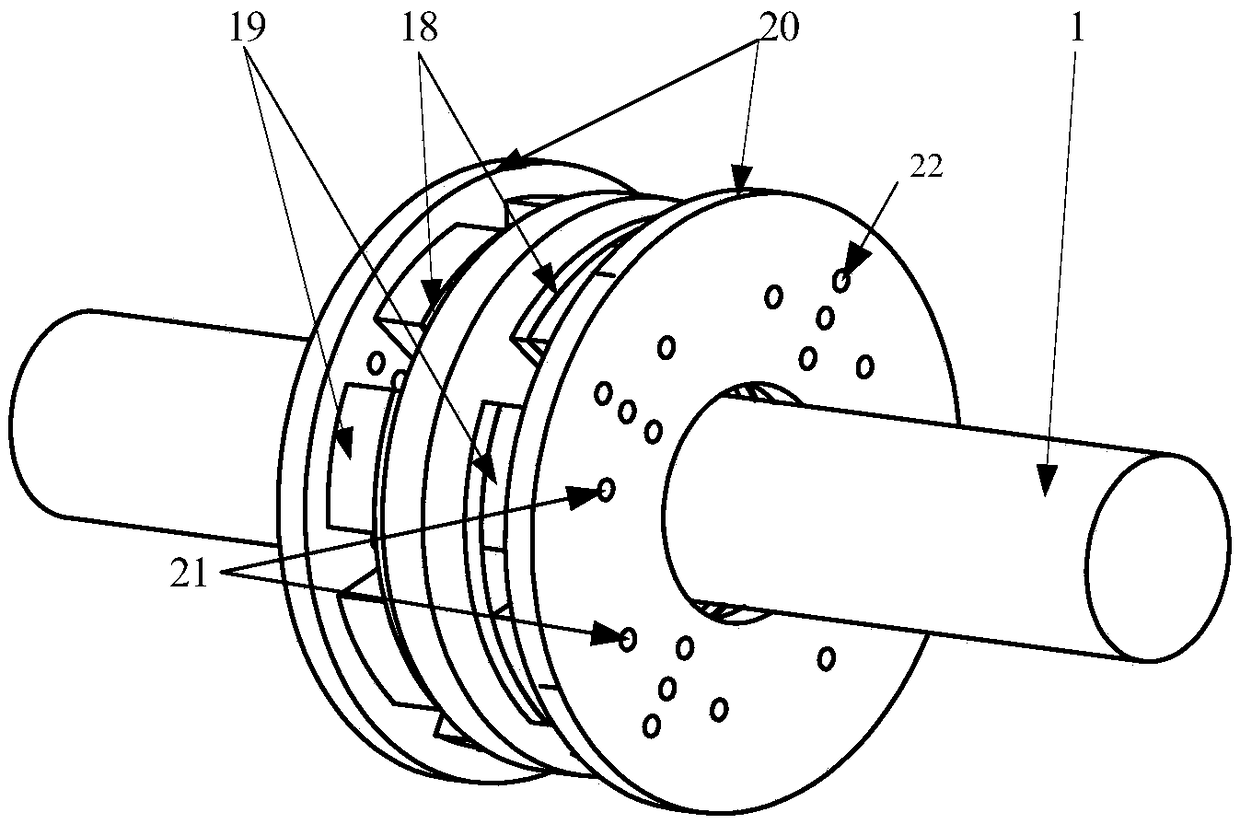

[0019] exist figure 1 and figure 2 In the schematic diagram of the electromagnetic-hydrostatic double-suspension thrust bearing shown, the rotating shaft 1 passes through two identical bushings 2. The bushing is composed of a circular groove and a round tube. The inner diameter of the round tube part of the bushing is Corresponding to the outer diameter of the shaft, such as Image 6 and Figure 8 As shown, a skeleton seal 7 is provided at the free end of the shaft sleeve round tube, and an annular groove is arranged on the inside of the shaft sleeve round tube adjacent to the skeleton seal. The straight grooves are connected to form a C-shaped oil return groove 15, and its two openings are located in the bottom of the shaft sleeve circular groove, and a groove is provided on the inner peripheral surface of the circular tube surrounded by each C-shaped oil return groove, which is a radial support cavity 16 , Each tank bottom is provided with an oil inlet B14, which is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com