Energy saving combustor using water gas fuels

A burner and water-using technology, applied to gas fuel burners, burners, combustion methods, etc., can solve problems such as drying green body heating, and achieve the effects of stabilizing wind pressure, prolonging mixing time, and slowing down flow velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings. It is only stated here that the words for directions such as up, down, left, right, front, back, inside, and outside that appear or will appear in the text of the present invention are only based on the accompanying drawings of the present invention, and are not specific to the present invention. limited.

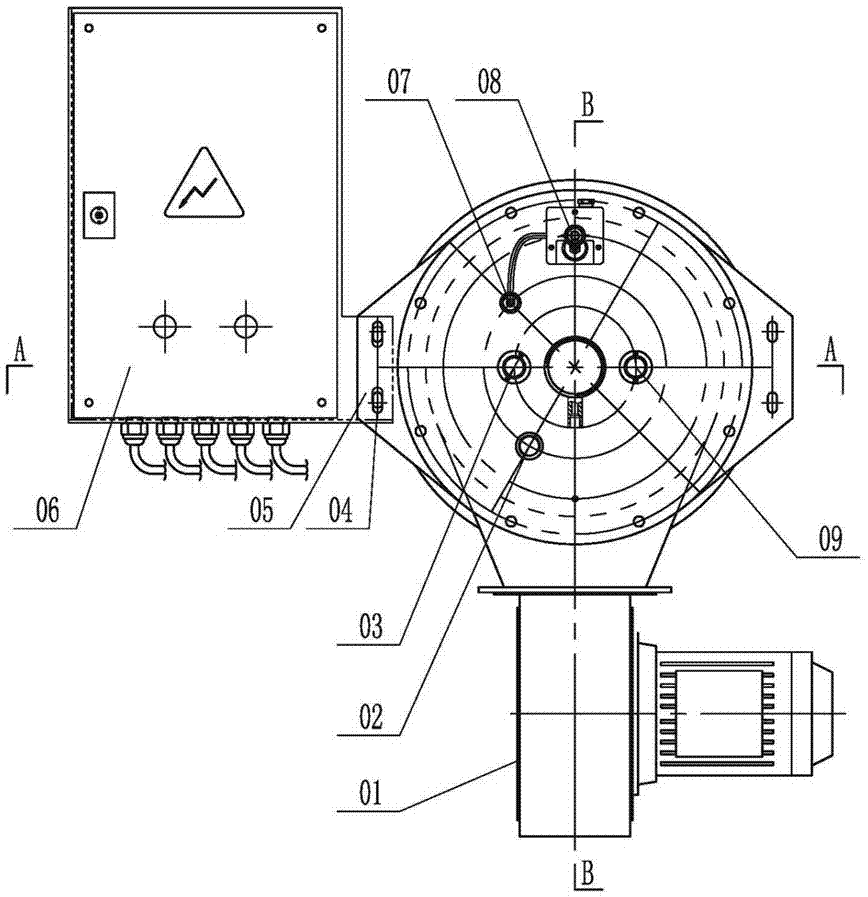

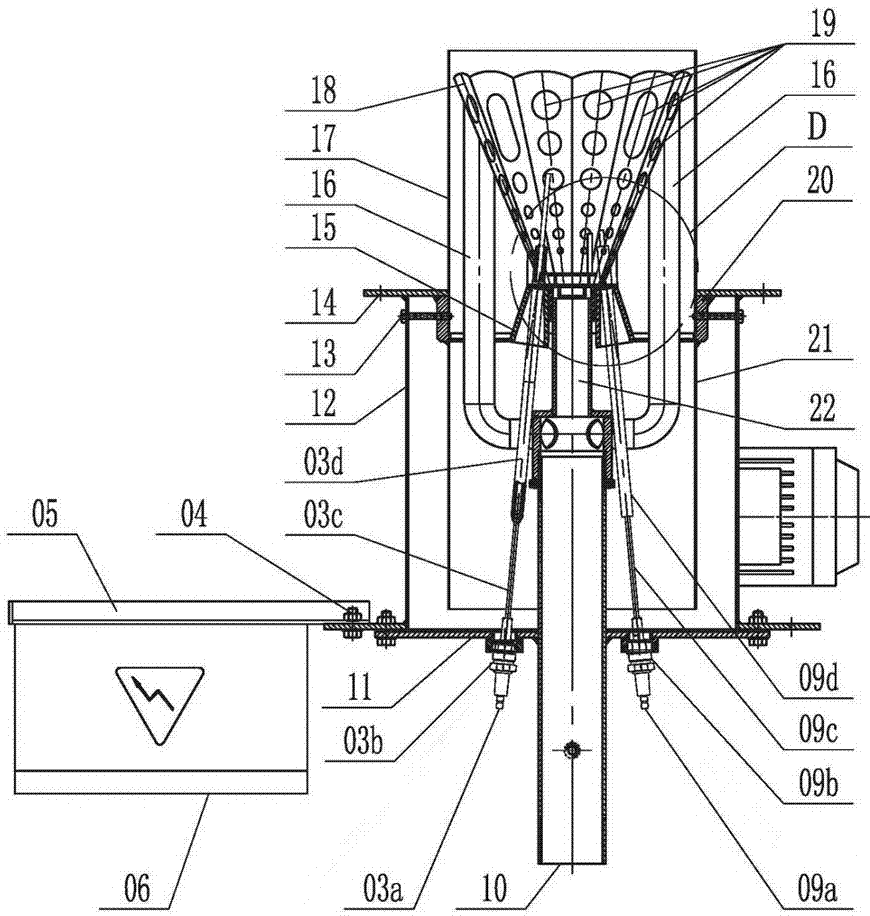

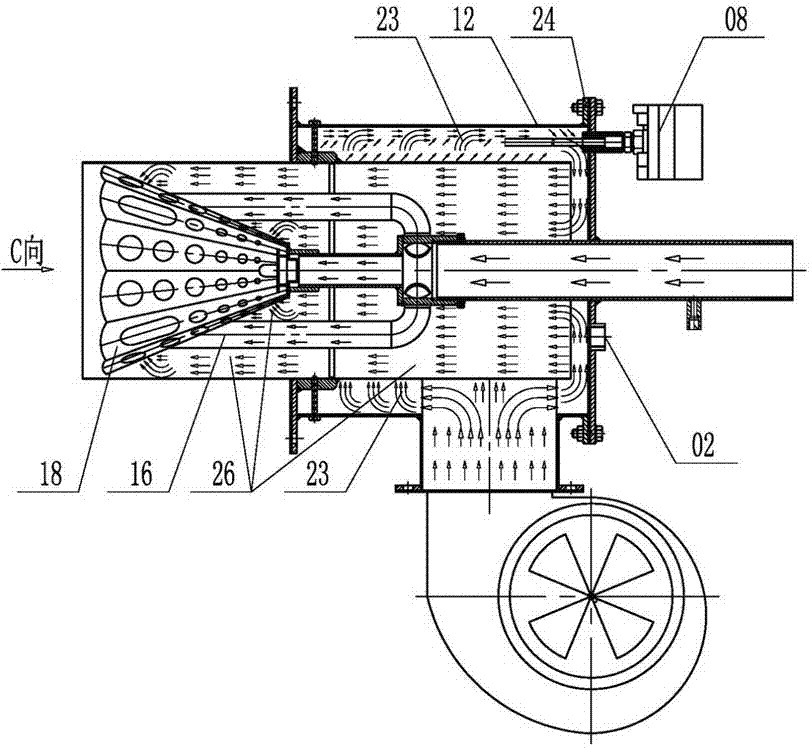

[0025] see Figure 1~4 , Figure 1~4 It shows the specific structure of the energy-saving burner using water gas fuel in the present invention, which uses low calorific value water gas as fuel, a high-power burner with a power exceeding 174kw-1740kw (calorific value about 150,000kcal / h-1,500,000kcal / h), a burner It can replace multiple conventional burners, so it can effectively simplify the pipeline structure of the drying kiln and solve the heating problem in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com