Automatic transmission for hybrid vehicle and method for controlling a hybrid vehicle

A hybrid vehicle and automatic transmission technology, which is applied in the fields of automatic transmissions, transmissions, and automatic transmissions, can solve problems such as the increase in the total volume of the power transmission system, the difficulty in the optimal efficiency area of the motor, and the reduction in the total energy performance of the vehicle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

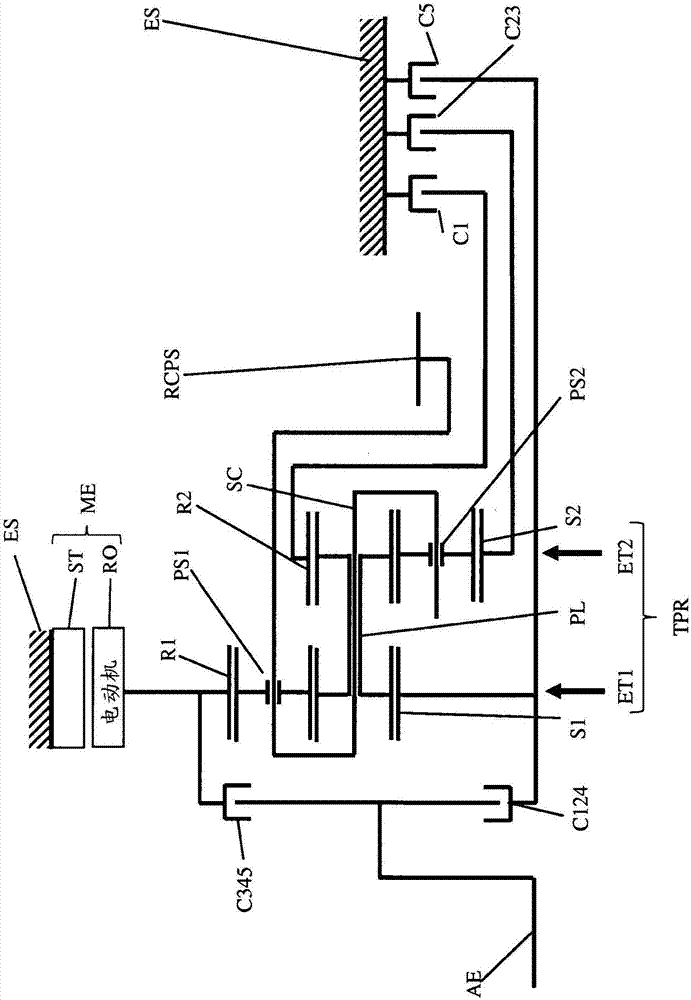

[0049] figure 1 and 6 An automatic transmission for a thermal / electric hybrid vehicle is schematically shown with:

[0050] – input shaft AE driven by heat engine,

[0051] – output wheel, output ring gear or output gear RCPS,

[0052] - fastening elements ES, such as housings,

[0053] - a motor ME, the stator ST of which is fixed to the fixture ES,

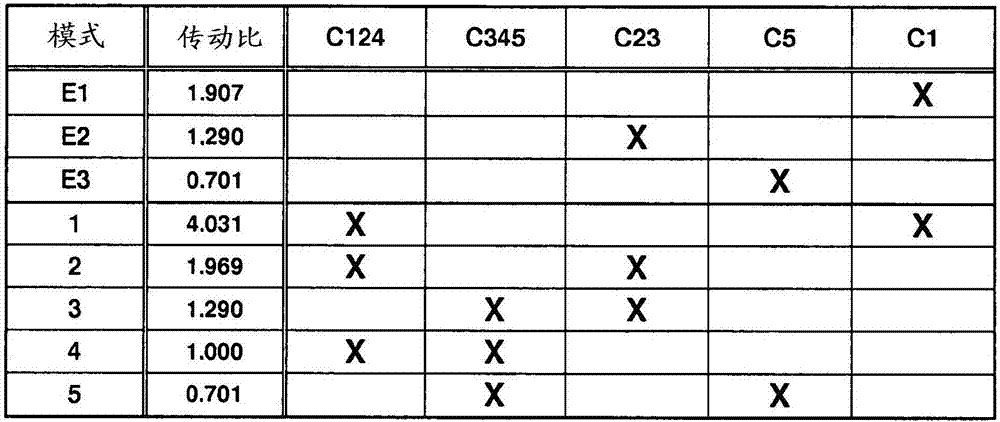

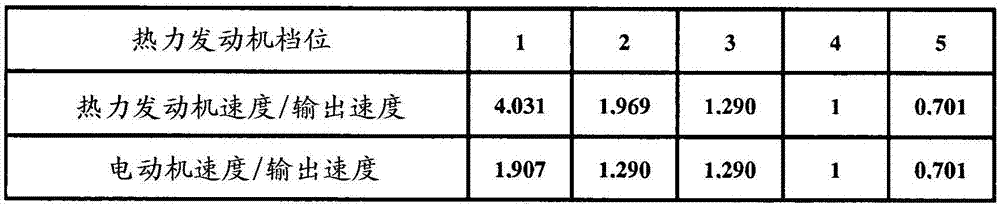

[0054] - first, second, third, fourth and fifth selective torque-transmitting mechanisms C124, C345, C1, C23, C5 which are selectively engageable or actuatable in order to establish, on the one hand, At least three speed ratios for driving the vehicle under the action of running, on the other hand at least five speed ratios are established for driving the vehicle under the action of the heat engine.

[0055] According to the invention, this transmission also has a single double planetary gear set TPR of the Lavigny Jooh type, which comprises the following components as constituent functional elements: first and second sun g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com