Device for exhaust waste heat recovery

A particle filter and regeneration process technology, applied in the electronic control of exhaust treatment devices, diagnostic devices of exhaust treatment devices, exhaust treatment, etc., can solve problems such as internal combustion engine damage, fuel consumption impact, impact, etc. Achieve the effect of reducing impact and prolonging the replacement interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

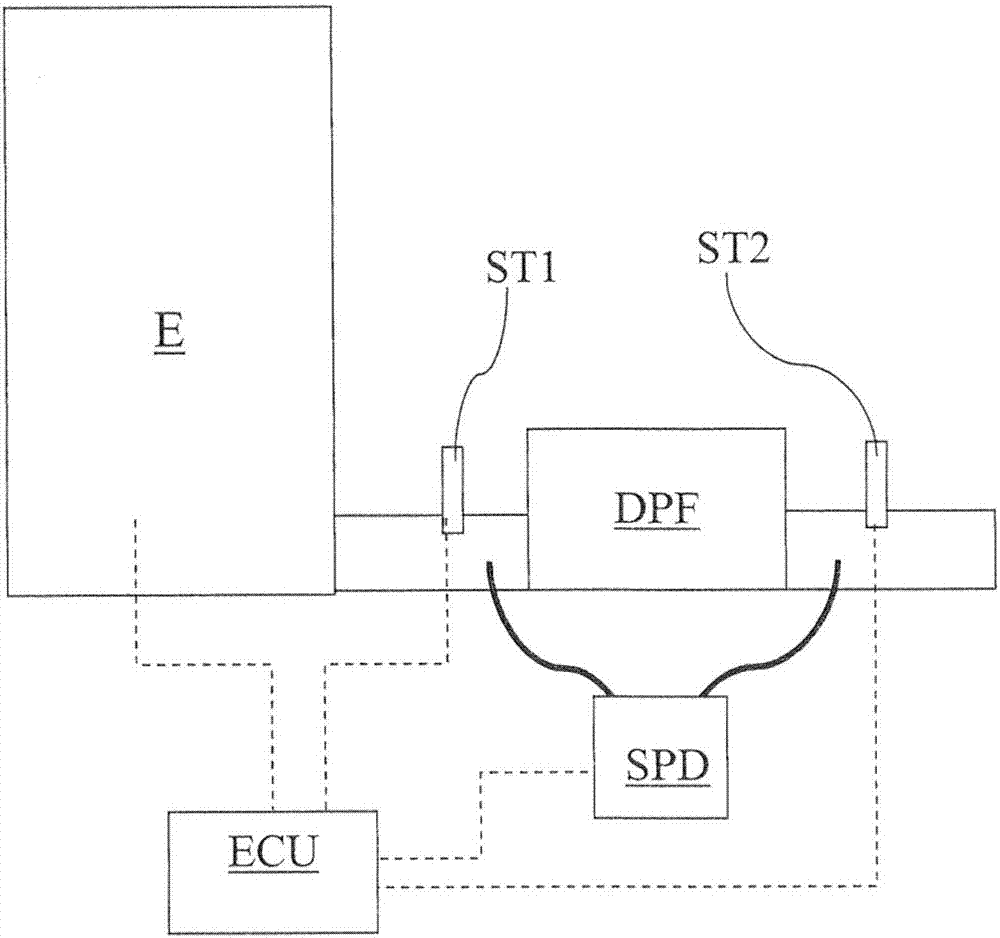

[0029] The method of the present invention will now be described, which is automatically activated when the process for regenerating the vehicle's DPF is initiated. After its activation, the method runs continuously and stops when the regeneration process is interrupted by the method.

[0030] According to the method of the present invention, the temperature is measured at the outlet of the DPF and the measured temperature is compared with a calculated theoretical value to obtain a temperature difference. When the temperature difference is below a first predetermined threshold, the regeneration process is interrupted.

[0031] In order to obtain the stability of the regeneration process, it is preferable to carry out the temperature monitoring after a predetermined time interval from the start of the regeneration process.

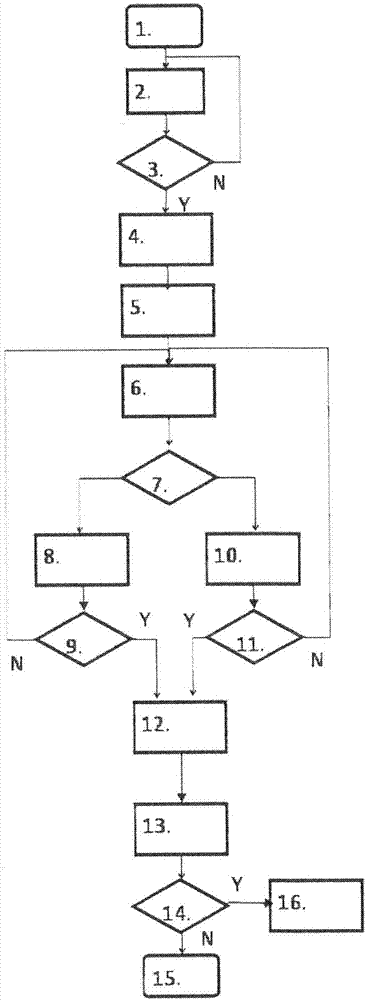

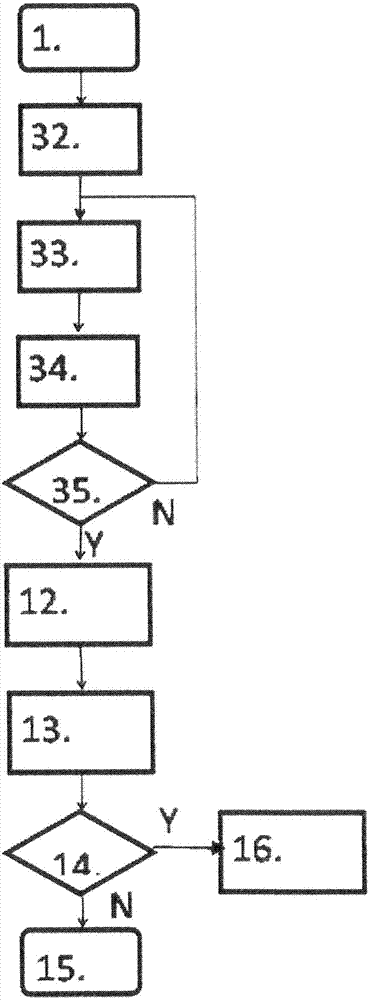

[0032] figure 1 A preferred embodiment of the first variant of the invention is shown by means of a flow chart comprising the following sequential steps....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com