Electrical functional component having a contact pin, and method for producing an electrical functional component

A technology of contact pins and contact elements, which is applied in the manufacture of contact parts, contact parts, cables/conductors, etc., can solve the problems of expensive processing, low contact quality, dispersion, etc., and achieve the effect of simplified tolerance balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

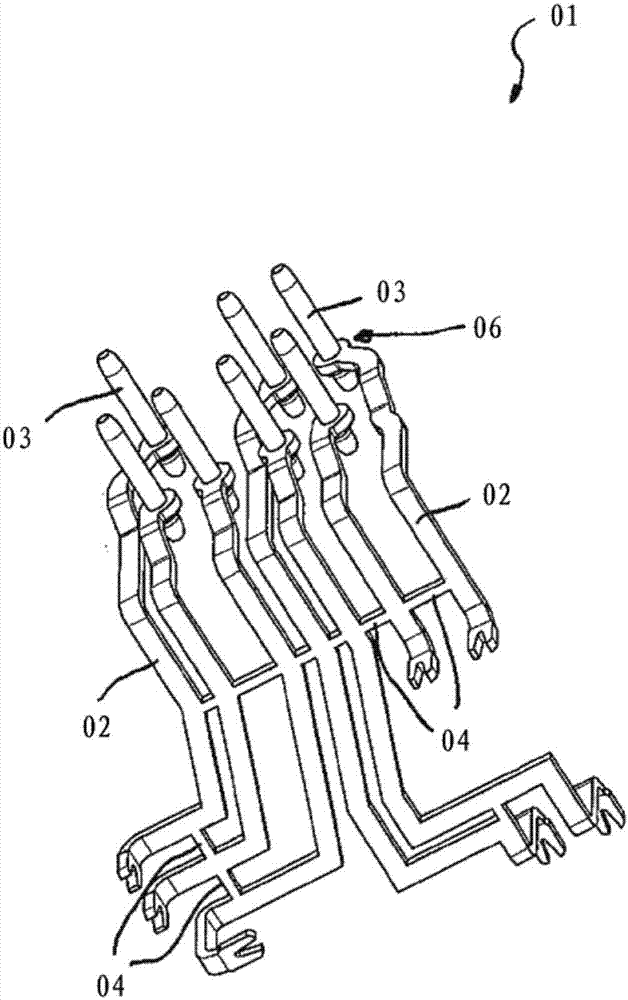

[0065] figure 1 An electrical functional part 01 is shown having a plurality of conductor tracks 02 , at the ends of which a contact pin 03 is each mounted in an electrically conductive manner. Contact pin 03 is used here to place the figure 1 A plug not shown in is attached to the functional part 01.

[0066] The conductor track 02 is produced by punching out a conductor plate, wherein initially a number of connection lugs 04 remain for assembly reasons. The connecting webs 04 are removed after the injection molding of the functional part 01 with plastic, so that all conductor tracks 02 are electrically insulated from one another.

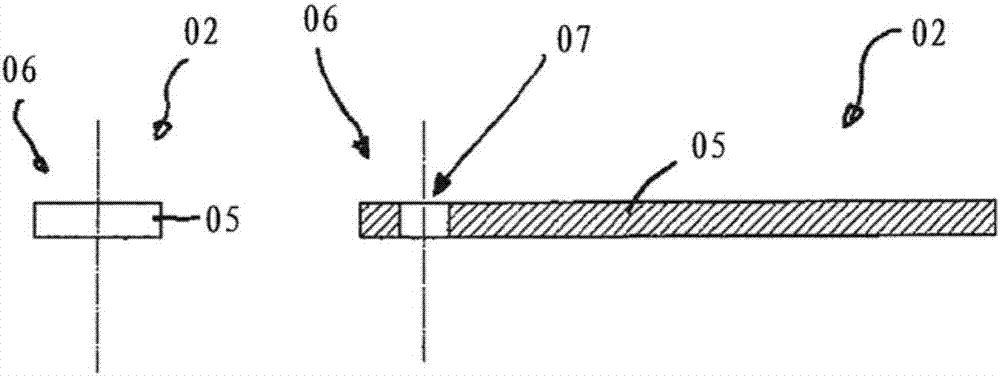

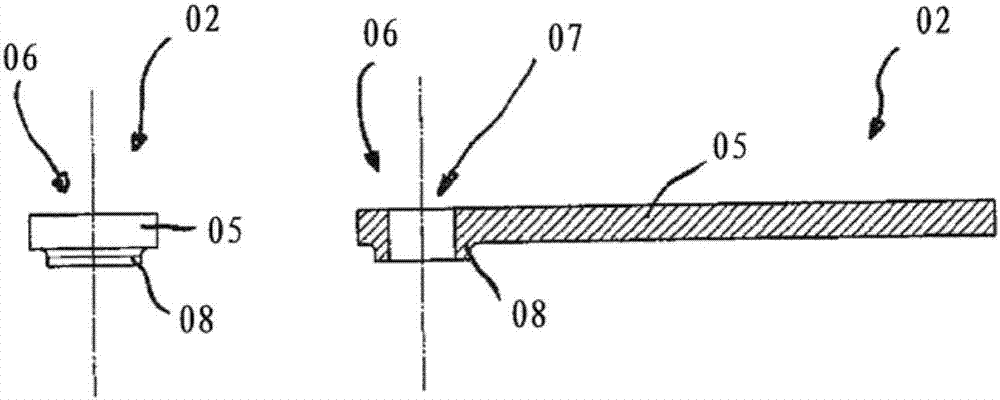

[0067] Between the conductor track 02 and the contact pin 03 there is in each case an electrically conductive contact area, so that an electrical current can be transmitted between the conductor track 02 and the contact pin 03 substantially without resistance. In this case, the electrical contact area between the conductor track 02 and the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com