High milk content frozen drink and preparation method thereof

A frozen drink and content technology, which is applied in the direction of fat-containing food ingredients, frozen sweets, food ingredients, etc., can solve the problems that need to be improved, and achieve the effect of strong stability, high nutritional value, and good flavor and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

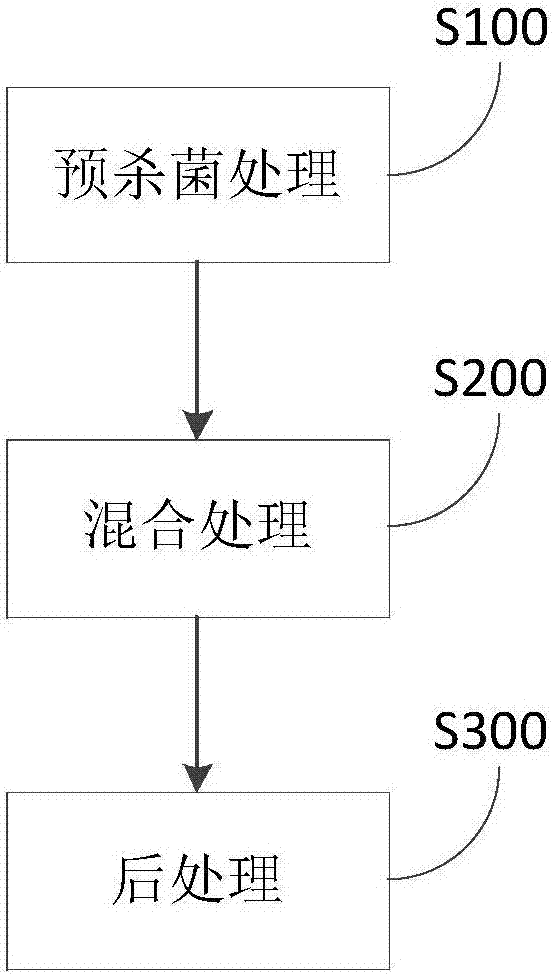

Method used

Image

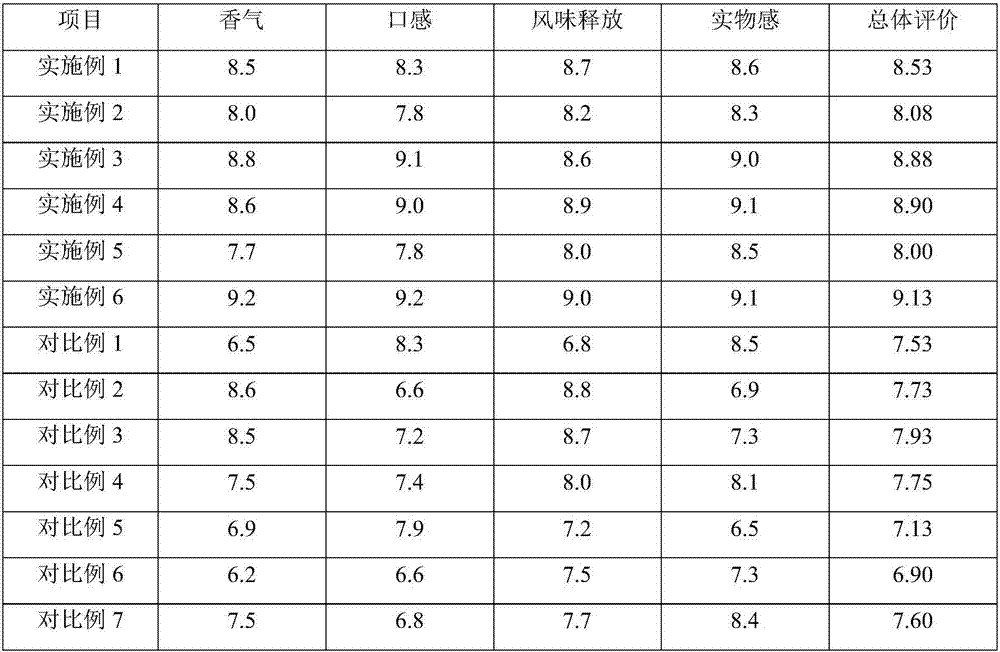

Examples

Embodiment 1

[0051] In this example, the frozen drink was prepared as follows:

[0052] 1. Raw materials (1000kg)

[0053] Raw milk: 500kg; Maltose syrup: 80kg; White sugar: 75kg; Skimmed milk powder: 50kg; Coconut oil: 60kg; 0.8kg; sodium alginate: 0.5kg; xanthan gum: 0.4kg; glyceryl monostearate: 2.2kg; food flavor: 1.0kg; the rest is drinking water.

[0054] 2. Production process

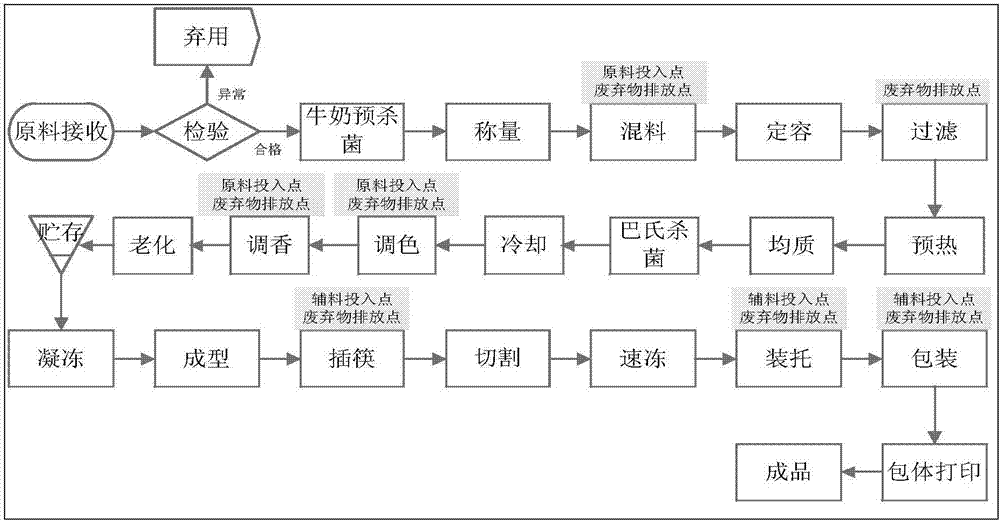

[0055] For details, see figure 2 ,in,

[0056] Pre-sterilization: Raw milk needs to be pre-sterilized at a temperature of 75°C for 15 seconds before being put into ingredients;

[0057] Mixing: Sodium alginate needs to be mixed with part of the white sugar first, soaked in warm water at 30-40°C for 3 hours until transparent, and then put in the ingredients. The order of mixing the materials is pre-sterilized milk, milk powder, part of the white sugar and Other stabilizers, sodium alginate soaking solution, vegetable oil, milk fat raw material, flavor and the remaining part of water pre-mixed with the re...

Embodiment 2

[0065] Prepare frozen drink according to the method for embodiment 1, difference is that raw material (1000kg) is as follows:

[0066] Raw milk: 400kg; Maltose syrup: 80kg; White sugar: 75kg; Skimmed milk powder: 50kg; Coconut oil: 60kg; Cream (milk fat content 33%): 80kg; kg; sodium alginate: 0.5kg; xanthan gum: 0.4kg; glyceryl monostearate: 1.6kg; polyglycerol fatty acid ester: 0.4kg; food flavor: 1.0kg; the rest is drinking water.

[0067] According to the frozen drink formula provided in this embodiment (conforming to the national standard for ice cream), through the above-mentioned production process, a milky-white semi-cream ice cream can be obtained, which has a delicate taste, good shape retention, and natural frankincense.

Embodiment 3

[0069] Prepare frozen drink according to the method for embodiment 1, difference is that raw material (1000kg) is as follows:

[0070] Raw milk: 600kg; Maltose syrup: 80kg; White sugar: 70kg; Skimmed milk powder: 50kg; Coconut oil: 60kg; Frozen cream (milk fat content: 44%): 50kg; ; Sodium alginate: 0.5kg; Xanthan gum: 0.4kg; Glyceryl monostearate: 2.0kg; Sucrose fatty acid ester: 0.2kg;

[0071] According to the frozen drink formula provided in this embodiment (conforming to the national standard for ice cream), through the above-mentioned production process, a milky-white semi-cream ice cream can be obtained, which has a delicate taste, good shape retention, and natural frankincense.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com