Preparation method of a low-heap specific gravity and high-activity low-temperature shift catalyst

A technology for changing the specific gravity of catalysts and piles. It is applied in the direction of catalyst activation/preparation, chemical instruments and methods, and physical/chemical process catalysts. It can solve problems such as increased bed resistance, more short films, and increased frequency of start-up and stop. and selectivity improvement, reduction of pulverization, and improvement of pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

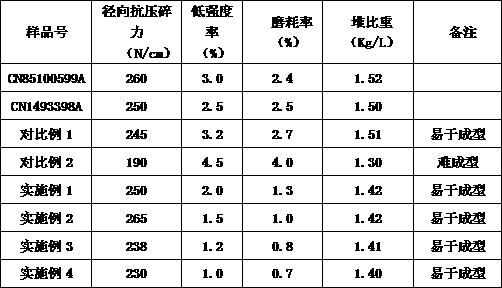

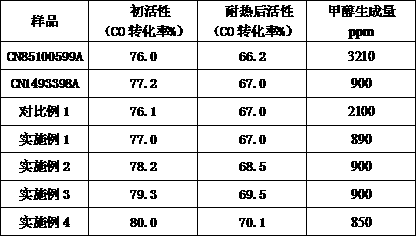

Embodiment 1

[0022] The copper-zinc-aluminum ternary material is obtained by the precipitation method, and the wet filter cake is obtained after washing and filtering. The wet filter cake is processed by two processes. One process is that the wet filter cake is put into the oven for drying, and the dry material is added to the mixer mill. Grinding, for every 120 Kg of dry material, add 30Kg of deionized water, the grinding time is 40min, granulate with an 8-mesh stainless steel screen, the particles enter the oven for drying, and the dry particles enter the roasting furnace for roasting to obtain cooked material 1, roasting The temperature is 320°C, and the roasting time is 90 minutes; another process is to directly add 0.5% of the beating material to the wet filter cake for beating, and the graphite is fully dissolved in deionized water and then evenly added to the beating material. For granulation, the particles are put into a roasting furnace to be roasted to obtain cooked particles 2, t...

Embodiment 2

[0024] The copper-zinc-aluminum ternary material is obtained by the precipitation method, and the wet filter cake is obtained after washing and filtering. The wet filter cake is processed by two processes. One process is that the wet filter cake is put into the oven for drying, and the dry material is added to the mixer mill. Grinding, for every 130 Kg of dry material, add 37Kg of deionized water, the grinding time is 50min, granulate with an 8-mesh stainless steel screen, the particles enter the oven for drying, and the dry particles enter the roasting furnace for roasting to obtain cooked material 1, roasting The temperature is 330°C, and the roasting time is 80 minutes; another process is to directly add 1.0% of the beating material to the wet filter cake for beating, and the graphite is fully dissolved in deionized water and then evenly added to the beating material. For granulation, the particles are put into a roasting furnace to be roasted to obtain cooked particles 2, t...

Embodiment 3

[0026] The copper-zinc-aluminum ternary material is obtained by the precipitation method, and the wet filter cake is obtained after washing and filtering. The wet filter cake is processed by two processes. One process is that the wet filter cake is put into the oven for drying, and the dry material is added to the mixer mill. Grinding, every time 140 Kg of dry material is milled, add 43Kg of deionized water, the grinding time is 55min, granulate with an 8-mesh stainless steel screen, the particles enter the oven for drying, and the dry particles enter the roasting furnace for roasting to obtain cooked material 1, roasting The temperature is 335°C, and the roasting time is 85 minutes; another process is to directly add 1.5% of the beating material to the wet filter cake for beating, and the graphite is fully dissolved in deionized water and then evenly added to the beating material. For granulation, the particles are put into a roasting furnace to be roasted to obtain cooked par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com