Vacuum pipeline ultra-high speed train

A vacuum pipeline and ultra-high-speed technology, applied to motor vehicles, electric vehicles, railway car bodies, etc., can solve the problems of airflow congestion, high energy consumption for passenger comfort, etc., to reduce resistance, eliminate shock wave resistance, and reduce aerodynamic resistance and the effect of frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the accompanying drawings and examples.

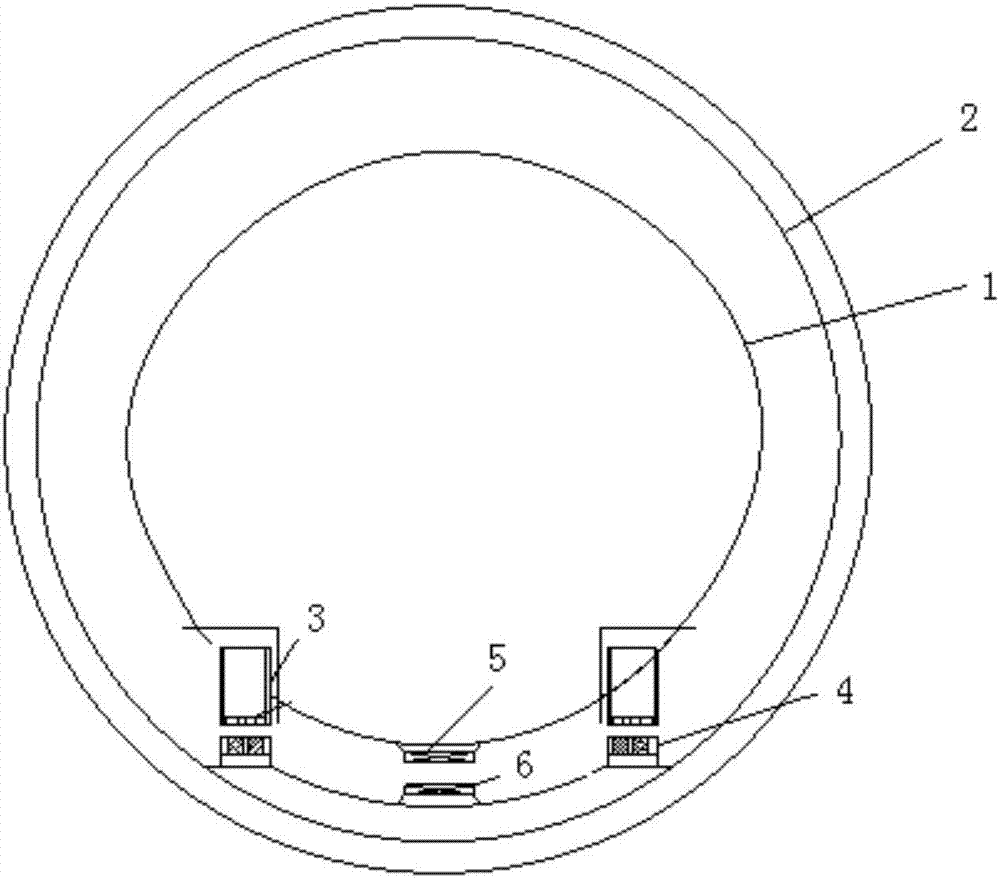

[0016] as attached figure 1 As shown, the present invention provides a vacuum tube ultra-high-speed train, which comprises a vacuum tube 2, a car body 1, a suspension device 3 on the car, a permanent magnet track 4, a vehicle-mounted propulsion device 5, a propulsion coil 6, and a vehicle-mounted battery and control system;

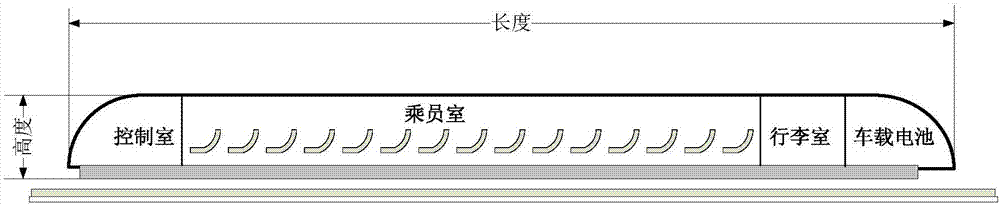

[0017] The interior space of the car body 1 is divided into a control room, a passenger room, a luggage room and an on-board battery room sequentially along the length direction.

[0018] Two rows of superconducting blocks and a suspension device 3 on the vehicle composed of two rows of superconducting blocks and a liquid nitrogen Dewar are installed side by side on the outer sides of the bottom of the vehicle body 1. The suspension device on the vehicle and the permanent magnetic track 4 laid on the inner bottom of the vacuum pipeli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com