Strip missing detection device and method for loading sealing case machine

A technology of packing and sealing machine and detection device, which is applied in the direction of measuring device, optical device exploration, packaging, etc., can solve the problems of increasing consumption, entering the market, wasting manpower and material resources, etc., and achieves the effect of stable operation and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, so as to make the technical solution of the present invention easier to understand and grasp.

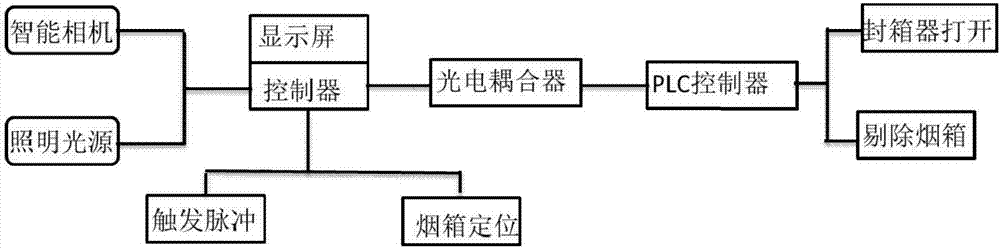

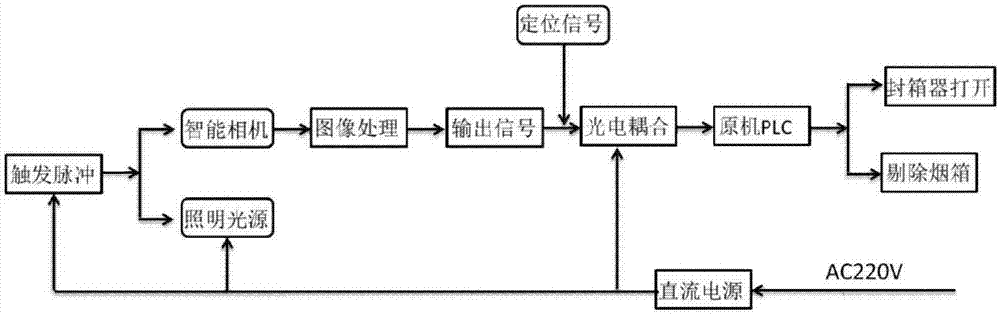

[0020] Such as figure 1 As shown, a YP13 cartoning and sealing machine strip missing detection device, its basic composition includes: industrial camera, strip lighting source, controller, trigger pulse photoelectric switch, smoke box positioning sensor, touch screen, photocoupler, DC Power supply, etc., industrial cameras, lighting sources, photoelectric switches, sensors, and controllers are connected to the control system of the original machine through photocouplers. Interrupting the production process enables automatic detection and rejection of products with defective bottom and top packaging in small boxes of transparent paper.

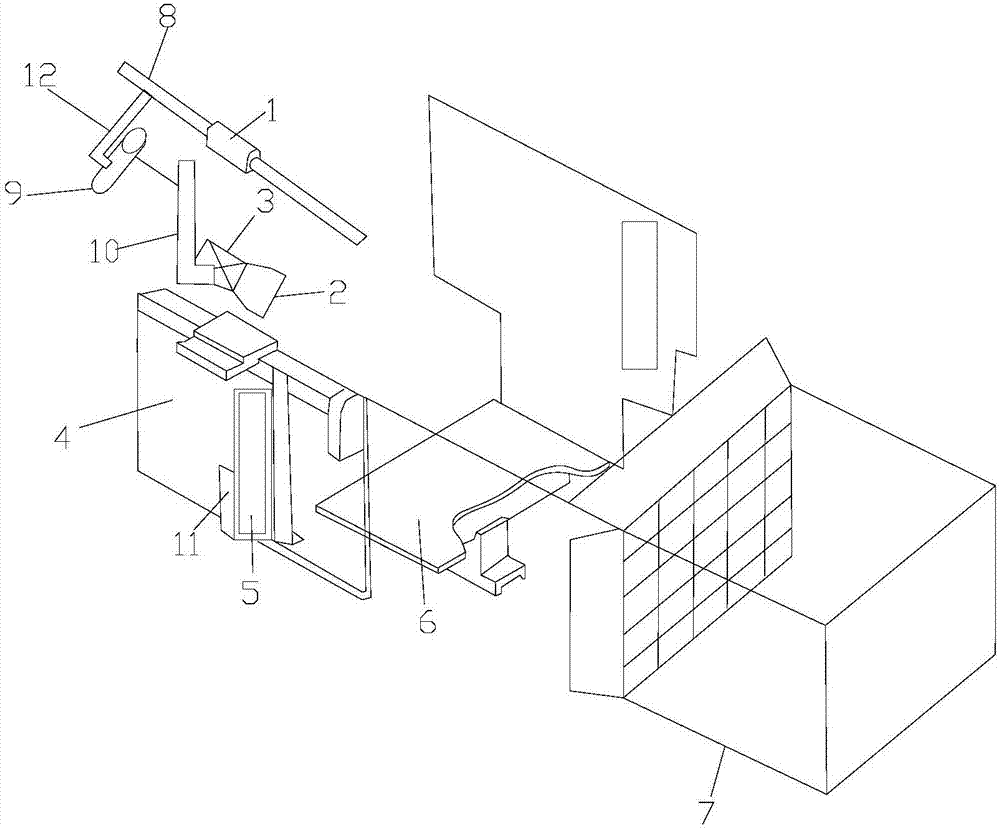

[0021] Such as figure 2 As shown, the industrial camera 3 is installed on the position above the YP1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com