A kind of preparation method of methyl three long-chain aliphatic ammonium carbonate

A hydrocarbyl ammonium carbonate, long-chain technology, applied in the preparation of organic carbonates, the preparation of amino compounds, the preparation of organic compounds, etc., can solve the problems of large consumption of acids and bases, complicated processes, impure products, etc., to reduce acidity. The effect of alkali consumption, expansion of application range and conversion rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

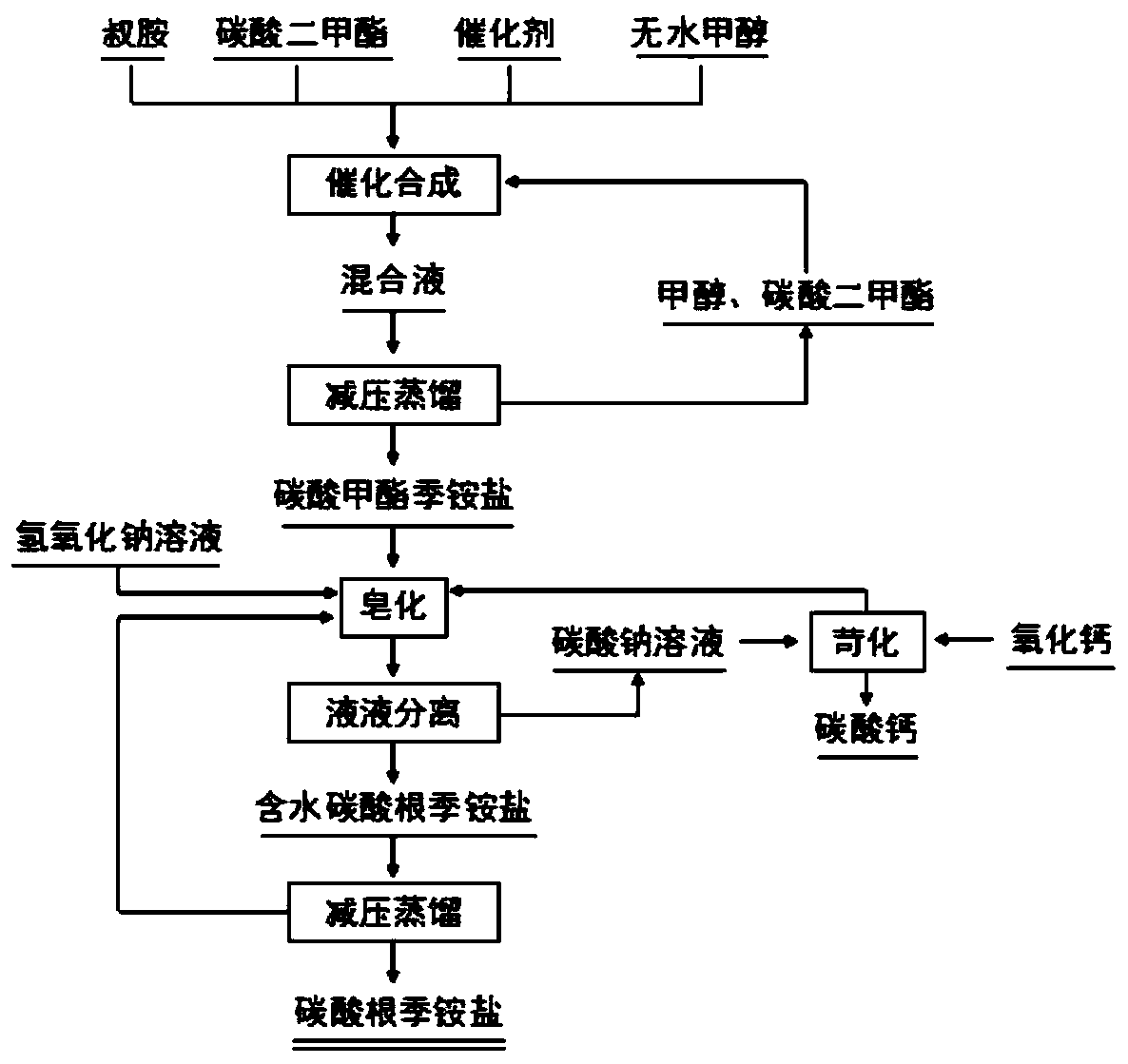

Method used

Image

Examples

Embodiment 1

[0037] Measure 240mL N235, 240mL dimethyl carbonate, 120mL anhydrous methanol, weigh 25.0g (trioctylmethyl quaternary ammonium bromide) catalyst, add it to a 1L autoclave, heat up to 110°C, and react at 1.1-2.4MPa After 8 hours, after the reaction stopped, it was cooled, and the solvent and unreacted dimethyl carbonate were distilled off under reduced pressure. The conversion of N235 was 95.39%. Add the distilled tri-long-chain fatty alkyl quaternary ammonium ester into 400 mL of potassium hydroxide solution with a concentration of 2 mol / L under stirring, and react at 80°C for 9 hours, then let stand to separate the phases, separate the oil phase and the water phase, The oil phase is carbonate-type quaternary ammonium salt (containing water, which can be removed under reduced pressure), with a yield of 93.77%, and wherein the content of bromine element is 1.67%.

Embodiment 2

[0039] Measure 240mL trioctyl tertiary amine, 240mL dimethyl carbonate, 120mL anhydrous methanol, add 27.8g (trioctylmethyl quaternary ammonium bromide) catalyst, add it to a 1L autoclave, raise the temperature to 115 ° C, at 1.7 ~2.7MPa reacted for 6 hours, after the reaction stopped, cooled, and evaporated the solvent and unreacted dimethyl carbonate under reduced pressure. The conversion rate of trioctyl tertiary amine is 97.19%. Add the distilled trioctyl methyl quaternary ammonium ester to 400mL sulfuric acid solution with a concentration of 2mol / L under stirring, react at room temperature for half an hour, let stand to separate the phases, separate the oil phase and the water phase, and the oil phase is sulfuric acid The root type quaternary ammonium salt (containing water, which can be removed under reduced pressure) has a yield of 95.83%, and wherein the bromine content is 1.85%.

Embodiment 3

[0041] Measure 240mL trioctyl tertiary amine, 240mL dimethyl carbonate, 120mL anhydrous methanol, add 28.0g (trioctylmethyl quaternary ammonium iodide) catalyst, add it to a 1L autoclave, raise the temperature to 110°C, at 1.75 ~2.7MPa reacted for 6 hours, after the reaction stopped, cooled, and evaporated the solvent and unreacted dimethyl carbonate under reduced pressure. The conversion rate of trioctyl tertiary amine is 92.78%. Add the distilled trioctylmethyl quaternary ammonium ester to 300mL hydrochloric acid solution with a concentration of 3mol / L under stirring, react at room temperature for half an hour, let stand to separate the phases, separate the oil phase and the water phase, and the oil phase is three Octylmethylammonium chloride (water-containing, decompressed to remove water), its yield is 94.27%, wherein the iodine element content is 2.33%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap