Method for improving the shape of non-oriented silicon steel sheet

A technology of steel plate shape and oriented silicon steel, which is applied in the field of improving hot-rolled steel plate shape, can solve the problems of insufficient improvement of steel plate shape and high temperature of strip steel, so as to improve rollability, uniform cooling, and increase yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

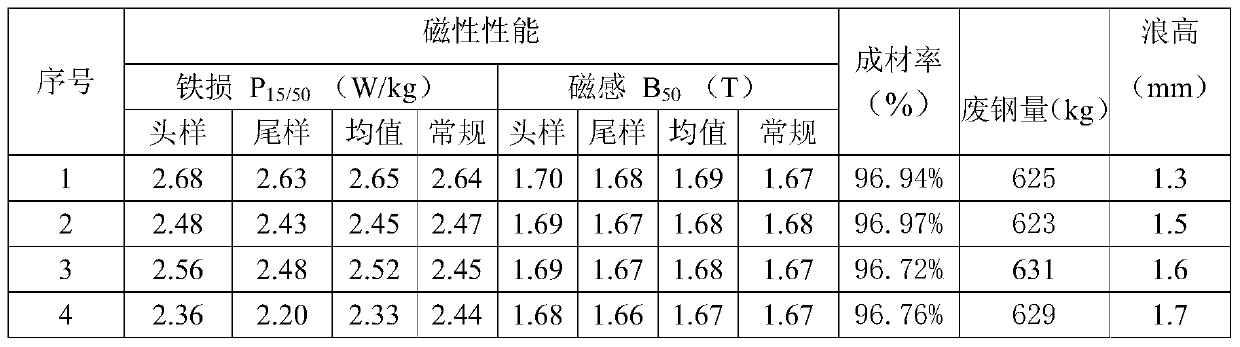

Examples

Embodiment 1-4

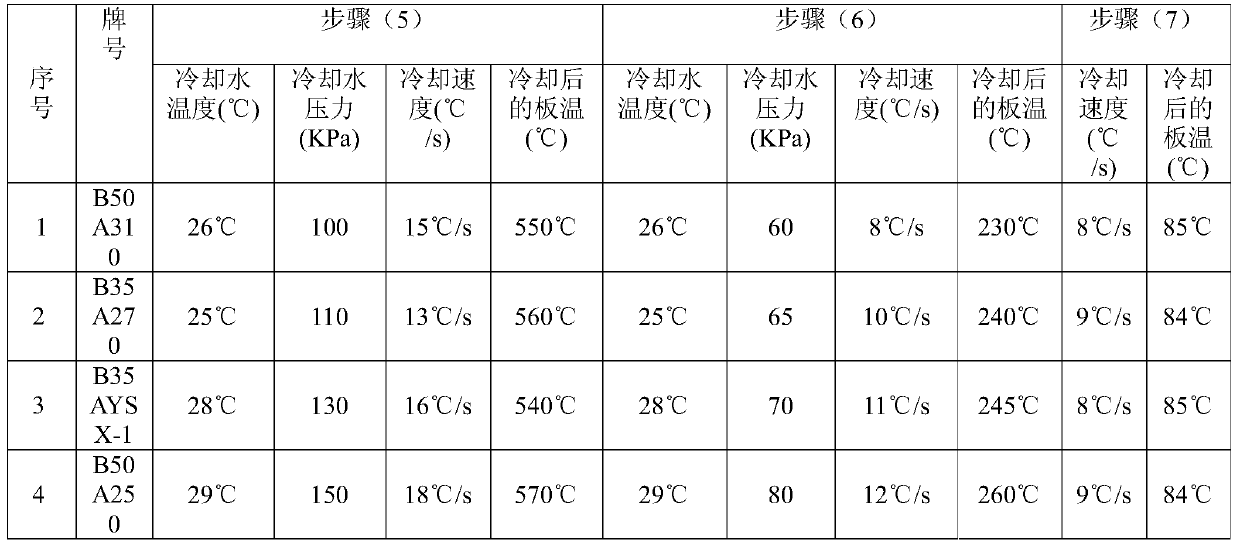

[0037] Continue to refer to Fig. 1, the method for improving the shape of non-oriented silicon steel sheet in embodiment 1-4 comprises carrying out normalized cooling step, cold rolling step and annealing coating step successively after making non-oriented silicon steel hot-rolled sheet, wherein, The normalizing cooling step comprises the following steps in turn (Table 1 shows the specific process parameters of the method for improving the shape of the non-oriented silicon steel sheet in the above-mentioned embodiments 1-4):

[0038] 1) Preheating: hot-rolled sheet is preheated from room temperature to 300-500°C;

[0039] 2) Non-oxidation heating: heat the hot-rolled sheet to 800-1000°C;

[0040] 3) Radiant tube heating and cooling: first heat the hot-rolled sheet to 900-1000°C by the radiant tube, and then cool it to 900-950°C by the radiant tube;

[0041] 4) Soaking by means of electricity or radiation: soaking temperature 850-900°C, cooling to 800-900°C;

[0042] 5) Rapid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com