Stator blade, compressor structure and compressor

A technology for stator blades and compressors, applied in the field of compressors, can solve the problem of high air flow mixing loss, and achieve the effects of improving aerodynamic efficiency and reducing air flow mixing loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

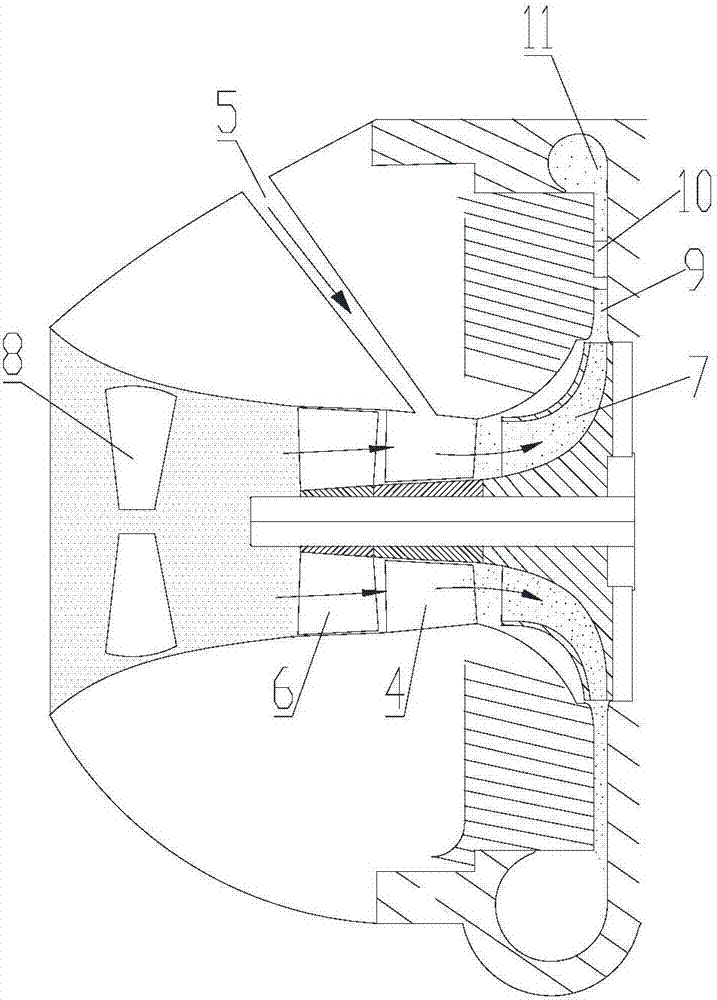

[0023] The centrifugal refrigerating compressor in the prior art adopts two-stage centrifugal impellers for compression and air supplementation in the middle. After the refrigerant is compressed by the first-stage impeller, it needs to be expanded by the diffuser, and then returned to the inlet of the second-stage impeller after passing through the diversion stage of the reflux device. The direction and size of the mainstream velocity are inconsistent, resulting in a large mixing loss.

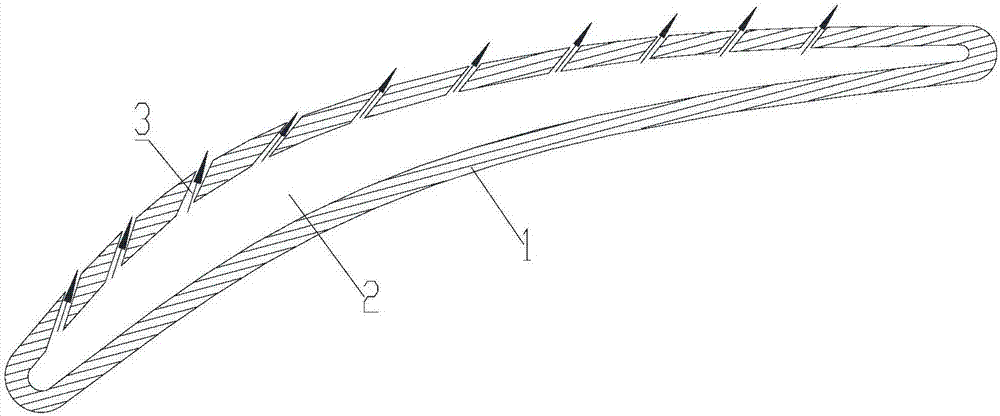

[0024] An embodiment of the present invention provides a stator vane, comprising: a vane body 1 , a cavity 2 is formed inside the vane body 1 , and an air supply hole 3 is formed on the vane body 1 . Preferably, the air supply holes 3 are arranged on the suction surface of the blade body 1 .

[0025]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com