Blowing and sucking combined material drying system and control method thereof

A drying system and material technology, which is applied to the dryer of static materials, biomass drying, drying gas layout, etc., can solve the problems of reducing boiler thermal efficiency, reducing combustion temperature, low drying efficiency, etc., to improve biomass combustion efficiency and The effects of thermal stability, improved heat exchange efficiency, and high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

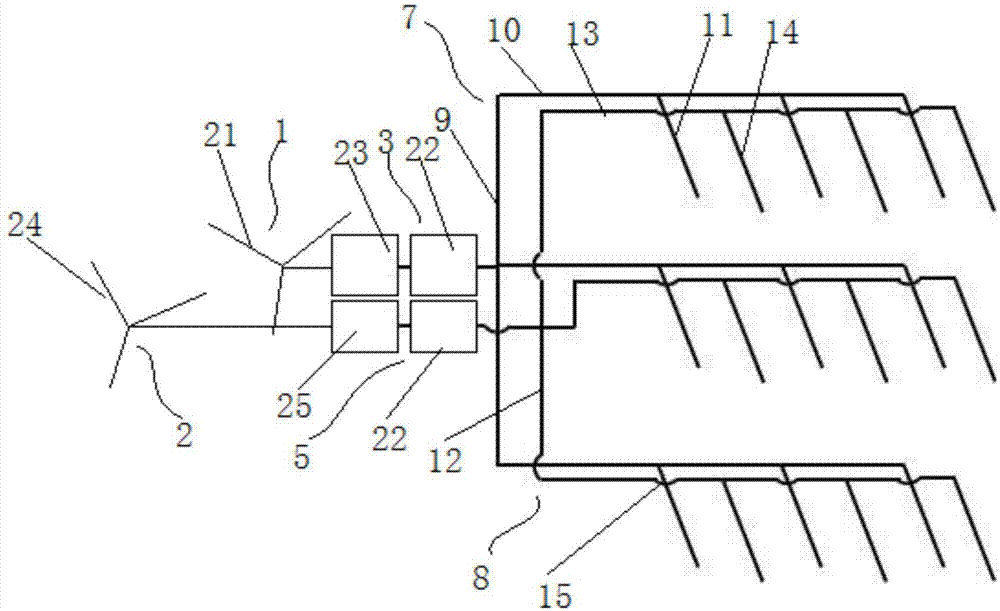

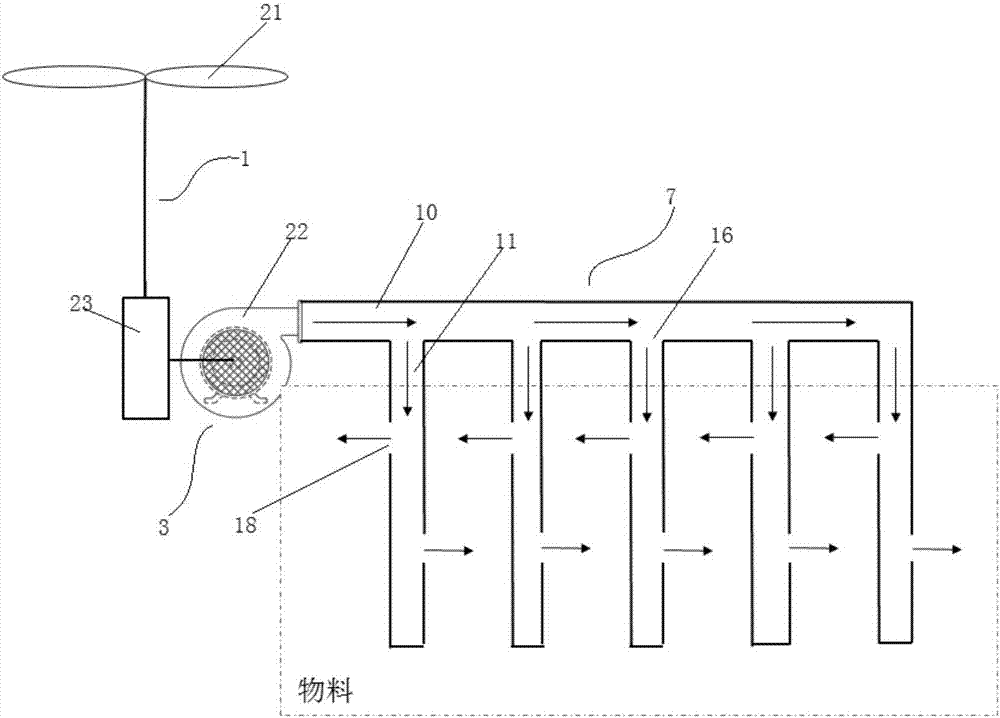

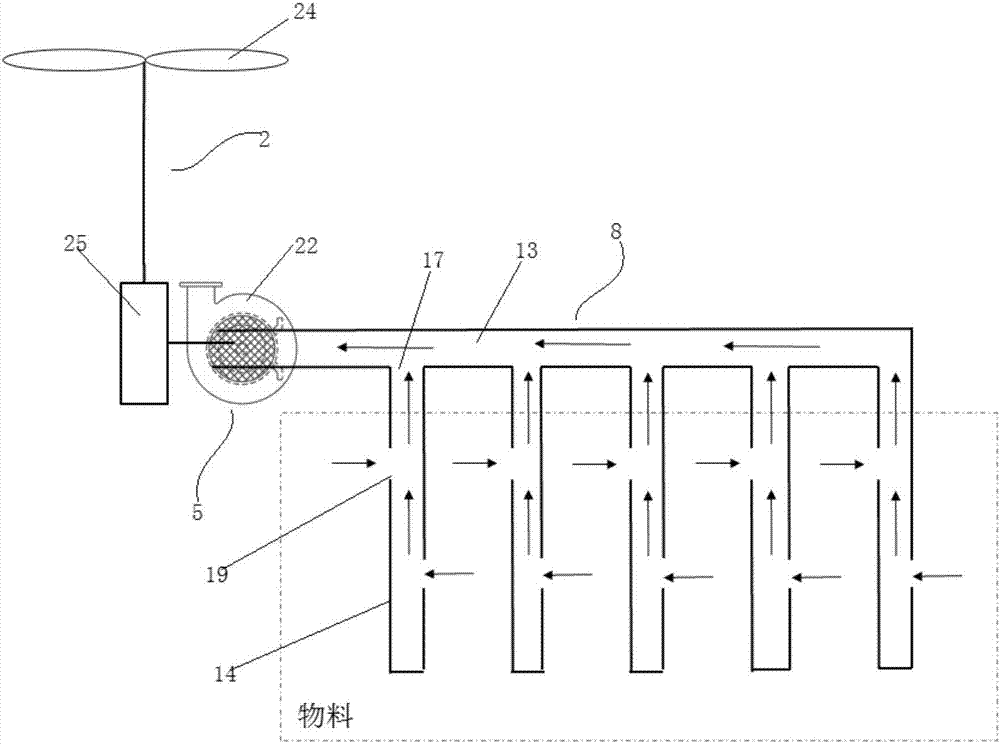

[0052] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0053] see in conjunction Figure 1 to Figure 11 As shown, according to the embodiment of the present invention, the blowing and suction combined material drying system includes: an air duct device, which is provided with air holes; The air part is connected to the air duct device and sucks air to the air duct device. The air holes on the air duct device can be used for blowing air or for sucking air, which is determined according to the structure of the air duct device and the function of the air hole.

[0054] When drying the material, the material can be blown dry and sucked dry alternately, and the high pressure of the blower can make the air flow reach all parts of the material more fully, and conduct more sufficient contact and heat exchange with the material, improving the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com